Key Insights

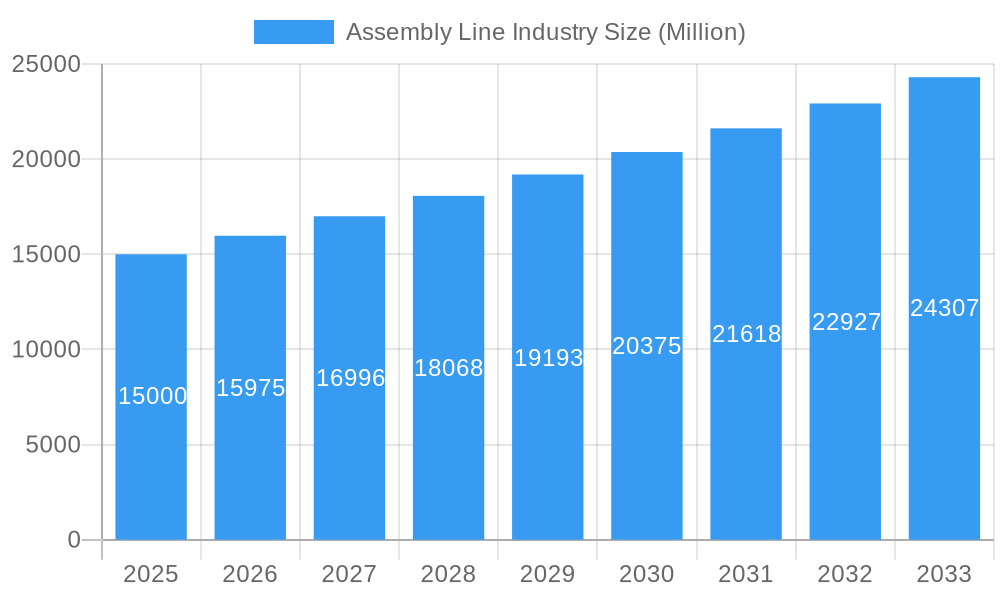

The global assembly line industry is poised for substantial expansion, driven by widespread automation adoption across manufacturing sectors. The market, valued at $307.15 billion in 2025, is projected to grow at a compound annual growth rate (CAGR) of 7.85% from 2025 to 2033. Key growth drivers include the escalating demand for efficient and flexible manufacturing processes in automotive, electronics, and food & beverage industries. Advancements in robotics, AI, and machine learning are enabling more sophisticated and adaptable assembly lines, enhancing productivity and reducing operational costs. The integration of Industry 4.0 technologies, including the Industrial Internet of Things (IIoT), further boosts efficiency and facilitates data-driven decision-making, propelling market growth.

Assembly Line Industry Market Size (In Billion)

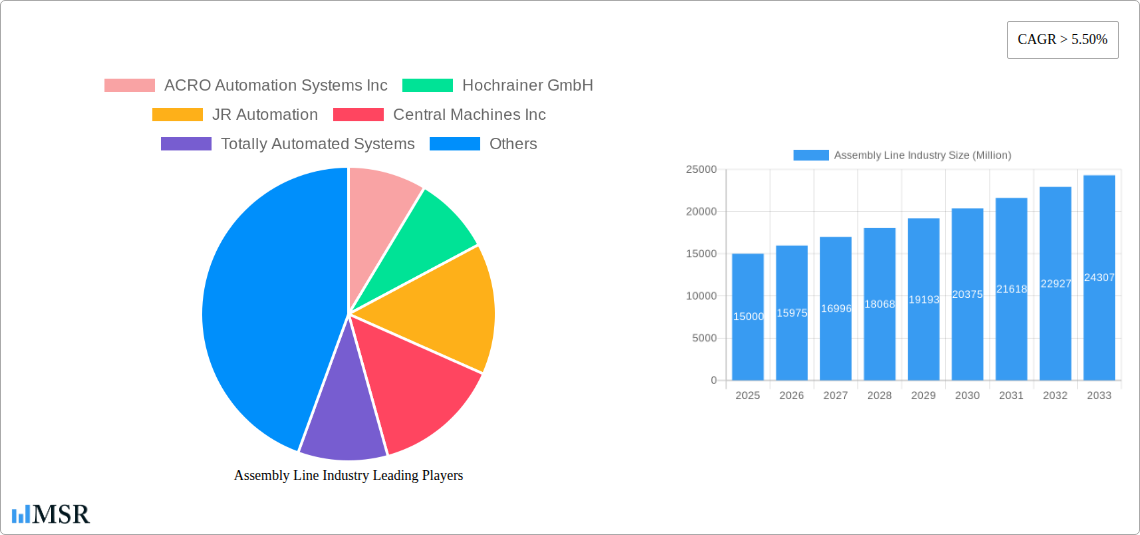

Challenges to market growth include high initial investment costs for advanced automation, which can hinder smaller enterprises. The requirement for skilled labor to operate and maintain complex systems also presents a significant hurdle, particularly in regions with workforce shortages. Supply chain disruptions and geopolitical uncertainties add to market volatility. Nevertheless, the long-term outlook remains positive, with ongoing innovation and technological advancements expected to mitigate these obstacles and sustain robust growth. The industry is segmented by automation type, industry application, and geography. Leading players such as ACRO Automation Systems Inc, Hochrainer GmbH, and JR Automation are actively influencing market dynamics through continuous product development and strategic partnerships.

Assembly Line Industry Company Market Share

Assembly Line Industry Market Report: 2019-2033

This comprehensive report provides a detailed analysis of the global Assembly Line Industry, offering invaluable insights for stakeholders seeking to navigate this dynamic market. With a study period spanning 2019-2033, a base year of 2025, and a forecast period of 2025-2033, this report provides a robust understanding of historical trends, current market dynamics, and future growth projections. The report includes extensive coverage of key players, including ACRO Automation Systems Inc, Hochrainer GmbH, JR Automation, and many more, offering a detailed competitive landscape analysis. The market is projected to reach xx Million by 2033, exhibiting a CAGR of xx%.

Assembly Line Industry Market Concentration & Dynamics

The global assembly line industry is characterized by a moderately concentrated market, with a few large multinational corporations holding significant market share. While precise figures are proprietary, we estimate the top 10 players control approximately xx% of the global market in 2025. This concentration is influenced by high barriers to entry, including substantial capital investment requirements for advanced automation technologies and specialized expertise. The industry is further shaped by a dynamic innovation ecosystem, with continuous technological advancements driving efficiency and productivity improvements. Regulatory frameworks, varying by region, play a crucial role, influencing safety standards, environmental regulations, and labor laws. Substitute products, such as manual assembly processes or alternative manufacturing methods, pose limited threats due to the inherent advantages of automation in terms of speed, precision, and cost-effectiveness in large-scale production.

- Market Share: Top 10 players estimated at xx% in 2025.

- M&A Activity: An estimated xx Million worth of M&A deals in the period 2019-2024, indicating significant consolidation within the industry. This trend is expected to continue with an estimated xx Million in projected M&A activity from 2025-2033.

- Innovation Ecosystem: Strong focus on collaborative robots (cobots), AI-powered automation, and predictive maintenance.

- End-User Trends: Growing demand for customized products and shorter production cycles are driving the adoption of flexible assembly lines.

Assembly Line Industry Industry Insights & Trends

The global assembly line industry is experiencing robust growth, driven by several key factors. The increasing demand for automation across various sectors, including automotive, electronics, and pharmaceuticals, is a major catalyst. Technological advancements, particularly in robotics, artificial intelligence (AI), and the Internet of Things (IoT), are significantly improving the efficiency and flexibility of assembly lines. Evolving consumer behaviors, such as a preference for customized products and faster delivery times, are further propelling the industry's growth. The market size was estimated at xx Million in 2024, and is projected to reach xx Million by 2033, demonstrating a significant expansion. This growth is fueled by a robust CAGR of xx% during the forecast period. Disruptions such as supply chain vulnerabilities and skilled labor shortages present challenges but simultaneously spur innovation in areas such as resilient supply chain management and the development of more autonomous assembly systems.

Key Markets & Segments Leading Assembly Line Industry

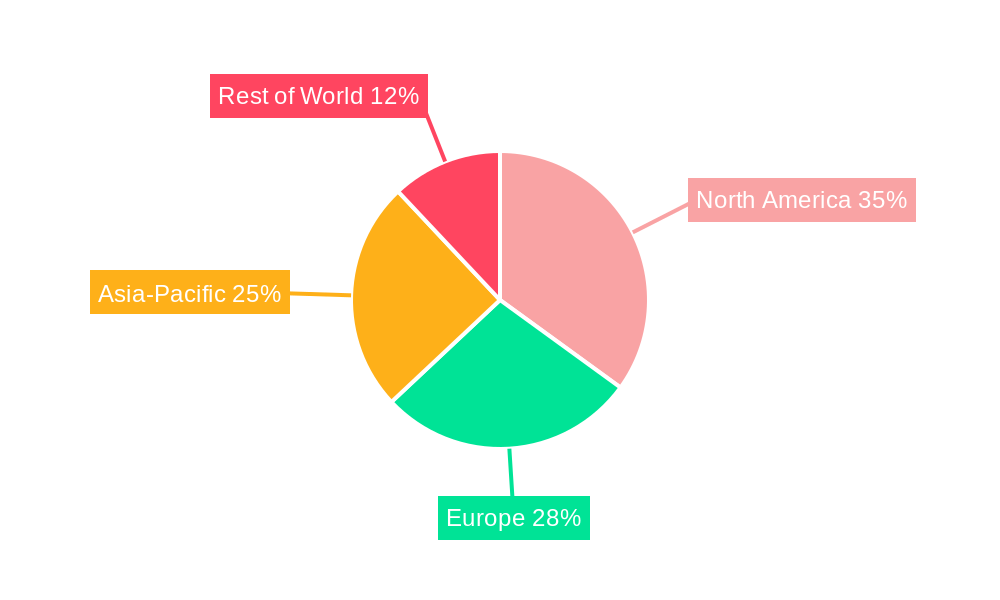

The Asia-Pacific region currently holds the dominant position in the global assembly line industry, driven by strong economic growth, rapid industrialization, and substantial investments in manufacturing infrastructure. China, in particular, plays a pivotal role, serving as a major manufacturing hub for numerous global companies.

- Drivers of Dominance in Asia-Pacific:

- Rapid economic growth and industrialization.

- Large and growing manufacturing sector.

- Significant investments in infrastructure and automation technologies.

- Increasing adoption of advanced manufacturing techniques like Industry 4.0.

- Favorable government policies supporting industrial development.

The automotive segment remains a significant driver of growth, with the increasing demand for electric vehicles (EVs) and autonomous driving technology further stimulating the need for advanced assembly lines. Other key segments include electronics, pharmaceuticals, food and beverage, and aerospace. However, the Asia-Pacific's dominance is gradually being challenged by the increasing automation within the North American and European markets, as well as the growing assembly line needs of developing economies in regions like South America and Africa.

Assembly Line Industry Product Developments

Recent product innovations focus on enhancing flexibility, efficiency, and safety. The integration of AI and machine learning enables predictive maintenance, reducing downtime and optimizing production schedules. Collaborative robots (cobots) are becoming increasingly prevalent, allowing for safer and more efficient human-robot collaboration. These advancements provide manufacturers with a competitive edge, enabling them to produce higher-quality products faster and at lower costs. The market sees continued integration of smart sensors, cloud computing, and advanced analytics enhancing real-time process monitoring, predictive maintenance, and overall efficiency improvements.

Challenges in the Assembly Line Industry Market

The assembly line industry faces several challenges, including regulatory hurdles related to safety, environmental concerns, and labor standards. Supply chain disruptions, particularly those related to semiconductor shortages and geopolitical instability, significantly impact production capacity and timelines. Intense competition, particularly from low-cost manufacturers in emerging economies, puts downward pressure on prices, impacting profitability. These factors, cumulatively, are estimated to cost the industry approximately xx Million in losses annually.

Forces Driving Assembly Line Industry Growth

Several key factors drive the growth of the assembly line industry. Technological advancements, particularly in robotics and AI, are enhancing efficiency and productivity. Strong economic growth in emerging markets fuels demand for automated manufacturing solutions. Favorable government policies supporting industrial development and automation adoption further contribute to industry expansion. For example, various government incentives and tax breaks have encouraged significant investments in automation across different regions.

Challenges in the Assembly Line Industry Market

Long-term growth will hinge on continued innovation, strategic partnerships, and market expansion. The development of more flexible and adaptable assembly lines will be crucial to meeting the increasing demand for customized products and shorter lead times. Collaborative efforts between manufacturers and technology providers are essential to accelerate the adoption of advanced technologies. Expansion into new and growing markets, particularly in developing economies, presents substantial opportunities for future growth.

Emerging Opportunities in Assembly Line Industry

Emerging opportunities lie in the development of more sustainable and environmentally friendly assembly lines. The increasing demand for customized products presents a significant opportunity to develop flexible and adaptable solutions. The integration of artificial intelligence (AI) and machine learning (ML) will significantly optimize production processes, improving efficiency and reducing costs. The use of digital twins for virtual commissioning and simulation offers substantial benefits in terms of reduced downtime and enhanced production planning.

Leading Players in the Assembly Line Industry Sector

- ACRO Automation Systems Inc

- Hochrainer GmbH

- JR Automation

- Central Machines Inc

- Totally Automated Systems

- Fusion Systems Group

- Adescor Inc

- Gemtec GmbH

- Markone Control Systems

- Eriez Manufacturing Co

- NEVMAT Australia PTY LTD

- RNA Automation

- UMD Automated Systems

- Mondragon Assembly

- Hitachi Power Solutions Co Ltd

- MechTech Automation Group

- RG-Luma Automation

- BBS Automation

- SITEC Industrietechnologie GmbH

List Not Exhaustive

Key Milestones in Assembly Line Industry Industry

- May 2021: Mondragon Assembly expands into the USA market with a new subsidiary in Chicago, enhancing its customer reach and service capabilities. This move signifies a strategic expansion into a key market, increasing competitive pressure and market share within the North American region.

- August 2021: JR Automation unifies its five divisional brands under a single corporate identity, streamlining operations and strengthening its market position. This consolidation improves brand recognition, enhances operational efficiency, and may lead to synergies in product development and market penetration.

Strategic Outlook for Assembly Line Industry Market

The future of the assembly line industry is bright, driven by continuous technological advancements, growing automation demand across various sectors, and the ongoing expansion of manufacturing activities globally. Strategic partnerships, strategic acquisitions, and the focus on sustainable manufacturing practices will play a pivotal role in shaping the industry's landscape in the coming years. The industry’s continued focus on optimizing efficiency, flexibility, and resilience will be critical to meeting evolving customer demands and navigating market uncertainties. Companies that successfully embrace innovation, digitalization, and sustainable practices are poised for significant growth and success.

Assembly Line Industry Segmentation

-

1. Type

- 1.1. Manual Assembly Lines

- 1.2. Semi-automated Assembly Lines

- 1.3. Fully Automated Assembly Lines

-

2. End-user

- 2.1. Automotive

- 2.2. Industrial Manufacturing

- 2.3. Electronics and Semiconductors

- 2.4. Medical & Pharmaceutical

- 2.5. Others

Assembly Line Industry Segmentation By Geography

- 1. North America

- 2. Asia Pacific

- 3. Europe

- 4. Latin America

- 5. Rest of the World

Assembly Line Industry Regional Market Share

Geographic Coverage of Assembly Line Industry

Assembly Line Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 7.85% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 3.4.1. Demand from Electric Vehicle Companies Driving the Market

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Assembly Line Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Type

- 5.1.1. Manual Assembly Lines

- 5.1.2. Semi-automated Assembly Lines

- 5.1.3. Fully Automated Assembly Lines

- 5.2. Market Analysis, Insights and Forecast - by End-user

- 5.2.1. Automotive

- 5.2.2. Industrial Manufacturing

- 5.2.3. Electronics and Semiconductors

- 5.2.4. Medical & Pharmaceutical

- 5.2.5. Others

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. Asia Pacific

- 5.3.3. Europe

- 5.3.4. Latin America

- 5.3.5. Rest of the World

- 5.1. Market Analysis, Insights and Forecast - by Type

- 6. North America Assembly Line Industry Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Type

- 6.1.1. Manual Assembly Lines

- 6.1.2. Semi-automated Assembly Lines

- 6.1.3. Fully Automated Assembly Lines

- 6.2. Market Analysis, Insights and Forecast - by End-user

- 6.2.1. Automotive

- 6.2.2. Industrial Manufacturing

- 6.2.3. Electronics and Semiconductors

- 6.2.4. Medical & Pharmaceutical

- 6.2.5. Others

- 6.1. Market Analysis, Insights and Forecast - by Type

- 7. Asia Pacific Assembly Line Industry Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Type

- 7.1.1. Manual Assembly Lines

- 7.1.2. Semi-automated Assembly Lines

- 7.1.3. Fully Automated Assembly Lines

- 7.2. Market Analysis, Insights and Forecast - by End-user

- 7.2.1. Automotive

- 7.2.2. Industrial Manufacturing

- 7.2.3. Electronics and Semiconductors

- 7.2.4. Medical & Pharmaceutical

- 7.2.5. Others

- 7.1. Market Analysis, Insights and Forecast - by Type

- 8. Europe Assembly Line Industry Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Type

- 8.1.1. Manual Assembly Lines

- 8.1.2. Semi-automated Assembly Lines

- 8.1.3. Fully Automated Assembly Lines

- 8.2. Market Analysis, Insights and Forecast - by End-user

- 8.2.1. Automotive

- 8.2.2. Industrial Manufacturing

- 8.2.3. Electronics and Semiconductors

- 8.2.4. Medical & Pharmaceutical

- 8.2.5. Others

- 8.1. Market Analysis, Insights and Forecast - by Type

- 9. Latin America Assembly Line Industry Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Type

- 9.1.1. Manual Assembly Lines

- 9.1.2. Semi-automated Assembly Lines

- 9.1.3. Fully Automated Assembly Lines

- 9.2. Market Analysis, Insights and Forecast - by End-user

- 9.2.1. Automotive

- 9.2.2. Industrial Manufacturing

- 9.2.3. Electronics and Semiconductors

- 9.2.4. Medical & Pharmaceutical

- 9.2.5. Others

- 9.1. Market Analysis, Insights and Forecast - by Type

- 10. Rest of the World Assembly Line Industry Analysis, Insights and Forecast, 2020-2032

- 10.1. Market Analysis, Insights and Forecast - by Type

- 10.1.1. Manual Assembly Lines

- 10.1.2. Semi-automated Assembly Lines

- 10.1.3. Fully Automated Assembly Lines

- 10.2. Market Analysis, Insights and Forecast - by End-user

- 10.2.1. Automotive

- 10.2.2. Industrial Manufacturing

- 10.2.3. Electronics and Semiconductors

- 10.2.4. Medical & Pharmaceutical

- 10.2.5. Others

- 10.1. Market Analysis, Insights and Forecast - by Type

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2025

- 11.2. Company Profiles

- 11.2.1 ACRO Automation Systems Inc

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Hochrainer GmbH

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 JR Automation

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 Central Machines Inc

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 Totally Automated Systems

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 Fusion Systems Group

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 Adescor Inc

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 Gemtec GmbH

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 Markone Control Systems

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Eriez Manufacturing Co

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 NEVMAT Australia PTY LTD

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.12 RNA Automation

- 11.2.12.1. Overview

- 11.2.12.2. Products

- 11.2.12.3. SWOT Analysis

- 11.2.12.4. Recent Developments

- 11.2.12.5. Financials (Based on Availability)

- 11.2.13 UMD Automated Systems

- 11.2.13.1. Overview

- 11.2.13.2. Products

- 11.2.13.3. SWOT Analysis

- 11.2.13.4. Recent Developments

- 11.2.13.5. Financials (Based on Availability)

- 11.2.14 Mondragon Assembly

- 11.2.14.1. Overview

- 11.2.14.2. Products

- 11.2.14.3. SWOT Analysis

- 11.2.14.4. Recent Developments

- 11.2.14.5. Financials (Based on Availability)

- 11.2.15 Hitachi Power Solutions Co Ltd

- 11.2.15.1. Overview

- 11.2.15.2. Products

- 11.2.15.3. SWOT Analysis

- 11.2.15.4. Recent Developments

- 11.2.15.5. Financials (Based on Availability)

- 11.2.16 MechTech Automation Group

- 11.2.16.1. Overview

- 11.2.16.2. Products

- 11.2.16.3. SWOT Analysis

- 11.2.16.4. Recent Developments

- 11.2.16.5. Financials (Based on Availability)

- 11.2.17 RG-Luma Automation

- 11.2.17.1. Overview

- 11.2.17.2. Products

- 11.2.17.3. SWOT Analysis

- 11.2.17.4. Recent Developments

- 11.2.17.5. Financials (Based on Availability)

- 11.2.18 BBS Automation

- 11.2.18.1. Overview

- 11.2.18.2. Products

- 11.2.18.3. SWOT Analysis

- 11.2.18.4. Recent Developments

- 11.2.18.5. Financials (Based on Availability)

- 11.2.19 SITEC Industrietechnologie GmbH**List Not Exhaustive

- 11.2.19.1. Overview

- 11.2.19.2. Products

- 11.2.19.3. SWOT Analysis

- 11.2.19.4. Recent Developments

- 11.2.19.5. Financials (Based on Availability)

- 11.2.1 ACRO Automation Systems Inc

List of Figures

- Figure 1: Global Assembly Line Industry Revenue Breakdown (billion, %) by Region 2025 & 2033

- Figure 2: North America Assembly Line Industry Revenue (billion), by Type 2025 & 2033

- Figure 3: North America Assembly Line Industry Revenue Share (%), by Type 2025 & 2033

- Figure 4: North America Assembly Line Industry Revenue (billion), by End-user 2025 & 2033

- Figure 5: North America Assembly Line Industry Revenue Share (%), by End-user 2025 & 2033

- Figure 6: North America Assembly Line Industry Revenue (billion), by Country 2025 & 2033

- Figure 7: North America Assembly Line Industry Revenue Share (%), by Country 2025 & 2033

- Figure 8: Asia Pacific Assembly Line Industry Revenue (billion), by Type 2025 & 2033

- Figure 9: Asia Pacific Assembly Line Industry Revenue Share (%), by Type 2025 & 2033

- Figure 10: Asia Pacific Assembly Line Industry Revenue (billion), by End-user 2025 & 2033

- Figure 11: Asia Pacific Assembly Line Industry Revenue Share (%), by End-user 2025 & 2033

- Figure 12: Asia Pacific Assembly Line Industry Revenue (billion), by Country 2025 & 2033

- Figure 13: Asia Pacific Assembly Line Industry Revenue Share (%), by Country 2025 & 2033

- Figure 14: Europe Assembly Line Industry Revenue (billion), by Type 2025 & 2033

- Figure 15: Europe Assembly Line Industry Revenue Share (%), by Type 2025 & 2033

- Figure 16: Europe Assembly Line Industry Revenue (billion), by End-user 2025 & 2033

- Figure 17: Europe Assembly Line Industry Revenue Share (%), by End-user 2025 & 2033

- Figure 18: Europe Assembly Line Industry Revenue (billion), by Country 2025 & 2033

- Figure 19: Europe Assembly Line Industry Revenue Share (%), by Country 2025 & 2033

- Figure 20: Latin America Assembly Line Industry Revenue (billion), by Type 2025 & 2033

- Figure 21: Latin America Assembly Line Industry Revenue Share (%), by Type 2025 & 2033

- Figure 22: Latin America Assembly Line Industry Revenue (billion), by End-user 2025 & 2033

- Figure 23: Latin America Assembly Line Industry Revenue Share (%), by End-user 2025 & 2033

- Figure 24: Latin America Assembly Line Industry Revenue (billion), by Country 2025 & 2033

- Figure 25: Latin America Assembly Line Industry Revenue Share (%), by Country 2025 & 2033

- Figure 26: Rest of the World Assembly Line Industry Revenue (billion), by Type 2025 & 2033

- Figure 27: Rest of the World Assembly Line Industry Revenue Share (%), by Type 2025 & 2033

- Figure 28: Rest of the World Assembly Line Industry Revenue (billion), by End-user 2025 & 2033

- Figure 29: Rest of the World Assembly Line Industry Revenue Share (%), by End-user 2025 & 2033

- Figure 30: Rest of the World Assembly Line Industry Revenue (billion), by Country 2025 & 2033

- Figure 31: Rest of the World Assembly Line Industry Revenue Share (%), by Country 2025 & 2033

List of Tables

- Table 1: Global Assembly Line Industry Revenue billion Forecast, by Type 2020 & 2033

- Table 2: Global Assembly Line Industry Revenue billion Forecast, by End-user 2020 & 2033

- Table 3: Global Assembly Line Industry Revenue billion Forecast, by Region 2020 & 2033

- Table 4: Global Assembly Line Industry Revenue billion Forecast, by Type 2020 & 2033

- Table 5: Global Assembly Line Industry Revenue billion Forecast, by End-user 2020 & 2033

- Table 6: Global Assembly Line Industry Revenue billion Forecast, by Country 2020 & 2033

- Table 7: Global Assembly Line Industry Revenue billion Forecast, by Type 2020 & 2033

- Table 8: Global Assembly Line Industry Revenue billion Forecast, by End-user 2020 & 2033

- Table 9: Global Assembly Line Industry Revenue billion Forecast, by Country 2020 & 2033

- Table 10: Global Assembly Line Industry Revenue billion Forecast, by Type 2020 & 2033

- Table 11: Global Assembly Line Industry Revenue billion Forecast, by End-user 2020 & 2033

- Table 12: Global Assembly Line Industry Revenue billion Forecast, by Country 2020 & 2033

- Table 13: Global Assembly Line Industry Revenue billion Forecast, by Type 2020 & 2033

- Table 14: Global Assembly Line Industry Revenue billion Forecast, by End-user 2020 & 2033

- Table 15: Global Assembly Line Industry Revenue billion Forecast, by Country 2020 & 2033

- Table 16: Global Assembly Line Industry Revenue billion Forecast, by Type 2020 & 2033

- Table 17: Global Assembly Line Industry Revenue billion Forecast, by End-user 2020 & 2033

- Table 18: Global Assembly Line Industry Revenue billion Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Assembly Line Industry?

The projected CAGR is approximately 7.85%.

2. Which companies are prominent players in the Assembly Line Industry?

Key companies in the market include ACRO Automation Systems Inc, Hochrainer GmbH, JR Automation, Central Machines Inc, Totally Automated Systems, Fusion Systems Group, Adescor Inc, Gemtec GmbH, Markone Control Systems, Eriez Manufacturing Co, NEVMAT Australia PTY LTD, RNA Automation, UMD Automated Systems, Mondragon Assembly, Hitachi Power Solutions Co Ltd, MechTech Automation Group, RG-Luma Automation, BBS Automation, SITEC Industrietechnologie GmbH**List Not Exhaustive.

3. What are the main segments of the Assembly Line Industry?

The market segments include Type, End-user.

4. Can you provide details about the market size?

The market size is estimated to be USD 307.15 billion as of 2022.

5. What are some drivers contributing to market growth?

N/A

6. What are the notable trends driving market growth?

Demand from Electric Vehicle Companies Driving the Market.

7. Are there any restraints impacting market growth?

N/A

8. Can you provide examples of recent developments in the market?

May 2021: Mondragon Assembly is expanding into the USA market. The opening of a new subsidiary in Chicago will enable Mondragon Assembly to provide a closer and personalized service to the customers in the country.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in billion.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Assembly Line Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Assembly Line Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Assembly Line Industry?

To stay informed about further developments, trends, and reports in the Assembly Line Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

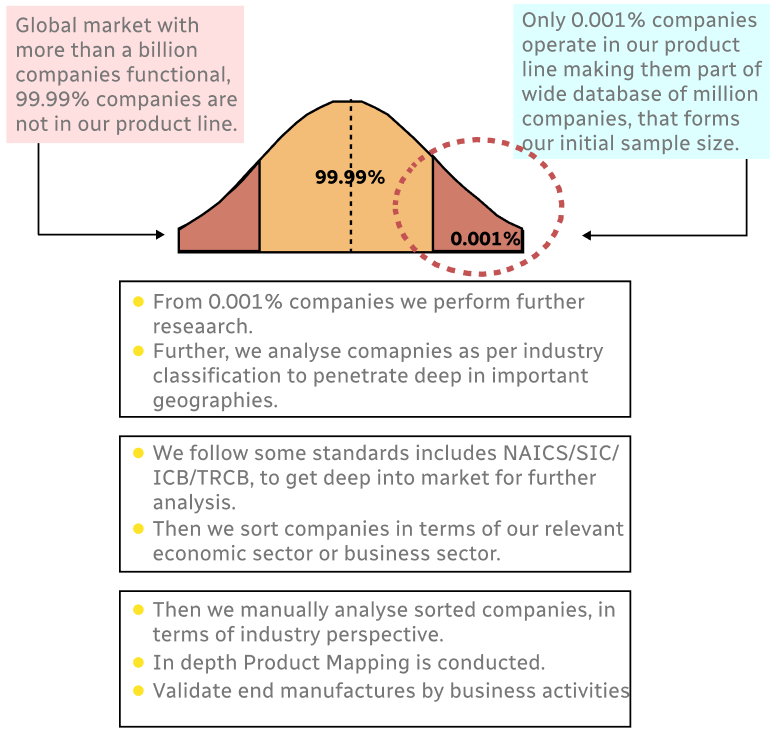

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

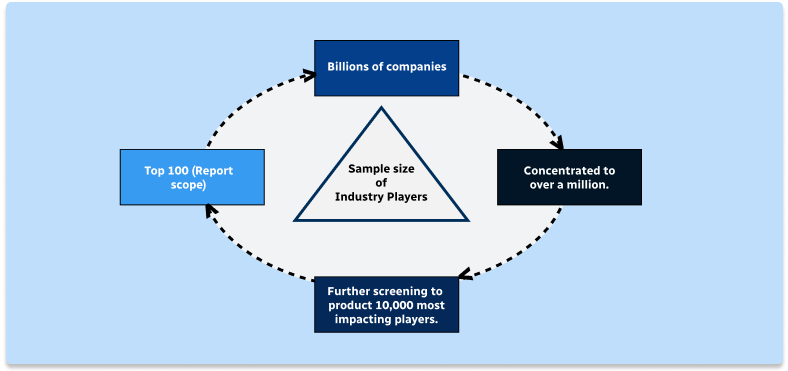

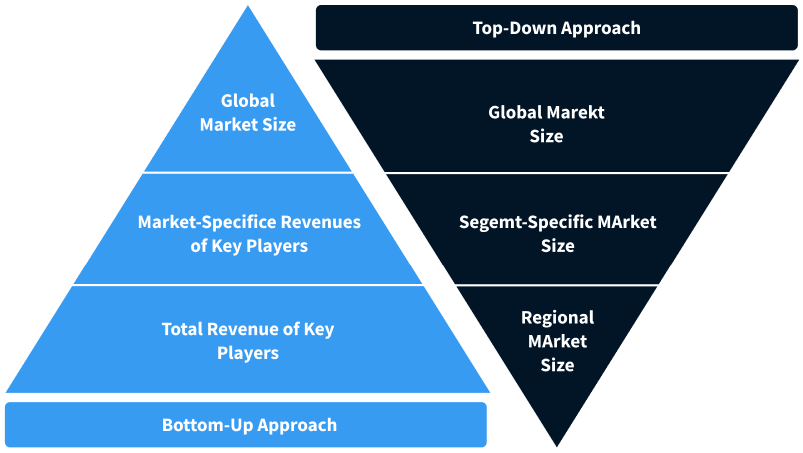

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

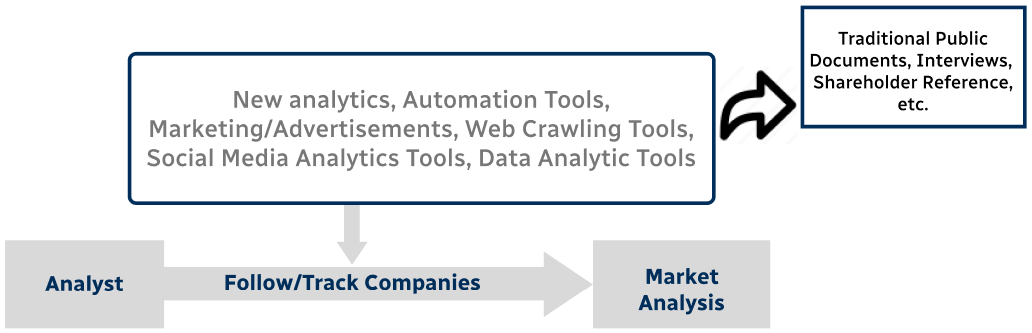

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence