Key Insights

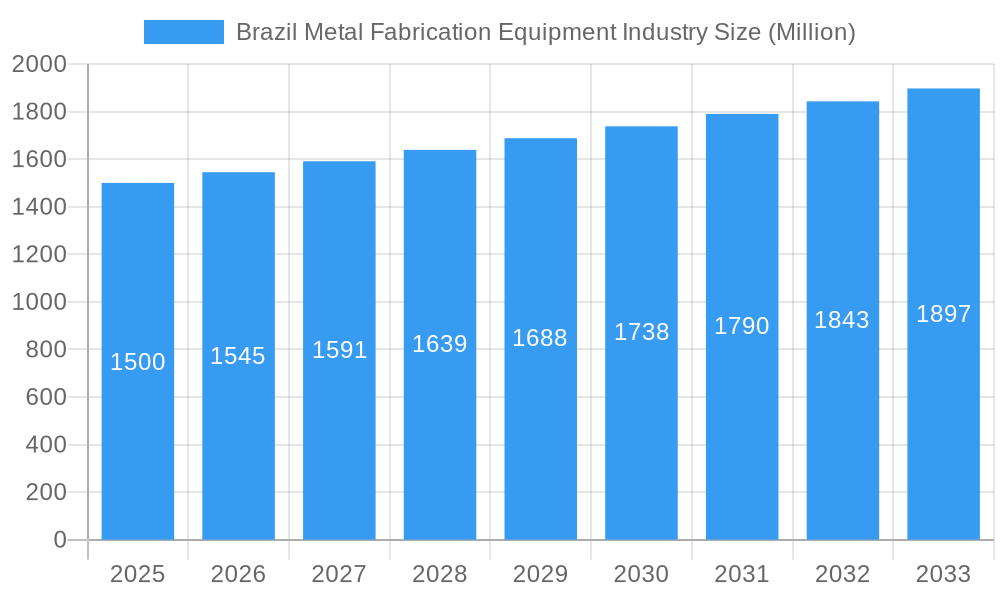

The Brazilian metal fabrication equipment market, valued at approximately $1.3 billion in the base year 2025, is poised for significant expansion. The market is projected to grow at a Compound Annual Growth Rate (CAGR) of 2.86% from 2025 to 2033. This growth is primarily driven by Brazil's expanding manufacturing sector, with key contributions from the automotive, construction, and energy industries. Increased investment in infrastructure development and rising demand for robust manufactured goods are further propelling market growth. Government-led initiatives aimed at modernizing industrial processes and upgrading manufacturing technologies, including incentives for automation and Industry 4.0 adoption in metal fabrication, are fostering a conducive environment for equipment acquisition. Potential headwinds include economic volatility, currency fluctuations, import tariffs, and a dependence on foreign technologies. The market exhibits segmentation across equipment types (e.g., laser cutting, bending, welding), applications (automotive, construction, aerospace), and geographical regions (Southeast, South, Northeast, etc.). Leading market participants, including BMA Brazil, Colfax, DMG Mori, Amada, Shenyang Machine Tool, Hurco, Kennametal, and MAG Giddings & Lewis, are actively competing by focusing on strategic alliances, tailored solutions, and comprehensive after-sales support to meet the evolving needs of the Brazilian market.

Brazil Metal Fabrication Equipment Industry Market Size (In Billion)

The forecast period anticipates sustained market growth, fueled by the increasing demand for automation and advanced technologies. Despite existing challenges, the market outlook remains optimistic, presenting substantial opportunities for both established and emerging companies. Key strategies for success in this dynamic market include forging strategic partnerships, establishing localized production capabilities, and delivering end-to-end solutions. A discernible trend towards more sustainable and energy-efficient equipment is expected as environmental consciousness intensifies.

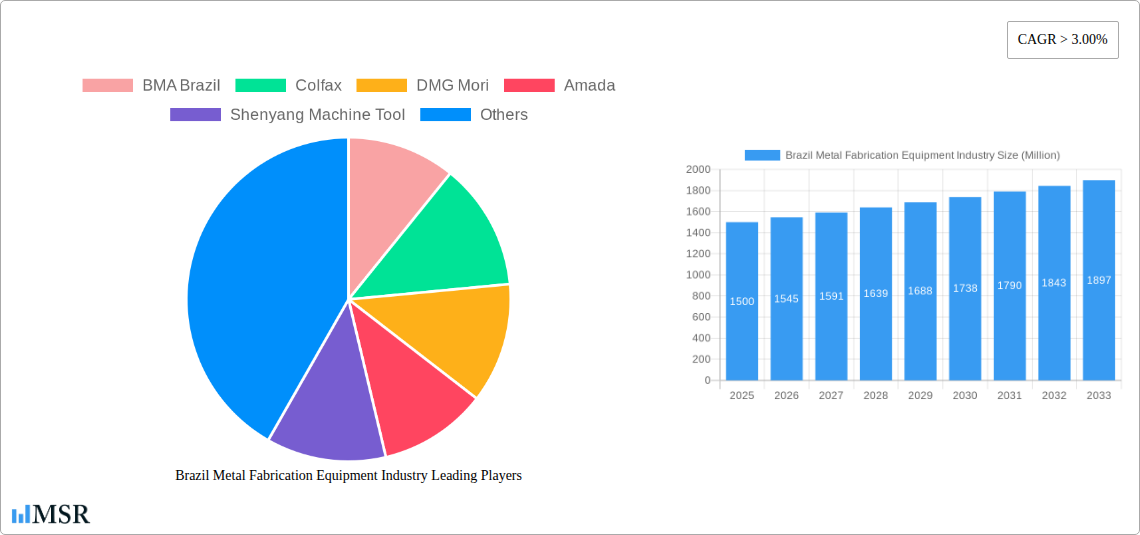

Brazil Metal Fabrication Equipment Industry Company Market Share

Brazil Metal Fabrication Equipment Industry: A Comprehensive Market Report (2019-2033)

This in-depth report provides a comprehensive analysis of the Brazil metal fabrication equipment industry, offering invaluable insights for stakeholders, investors, and industry professionals. Covering the period 2019-2033, with a base year of 2025 and a forecast period of 2025-2033, this report unveils market dynamics, growth drivers, challenges, and emerging opportunities within this dynamic sector. The study utilizes extensive data analysis and expert insights to deliver actionable intelligence on market size (valued at xx Million in 2025), CAGR, key segments, and leading players.

Brazil Metal Fabrication Equipment Industry Market Concentration & Dynamics

The Brazilian metal fabrication equipment market exhibits a moderately concentrated structure, with a few major international and domestic players holding significant market share. BMA Brazil, for example, commands an estimated xx% market share in the segment, while other multinational corporations like Amada and DMG Mori hold substantial positions. The market's competitive landscape is characterized by intense rivalry, driving innovation and price competition.

Market Dynamics:

- Innovation Ecosystems: The industry is witnessing a gradual shift towards Industry 4.0 technologies, with increased adoption of automation, robotics, and digitalization in manufacturing processes.

- Regulatory Frameworks: Brazilian regulations concerning industrial safety and environmental standards significantly impact market dynamics. Compliance costs and evolving norms influence equipment choices.

- Substitute Products: The availability of used equipment and alternative manufacturing processes presents a competitive challenge for new equipment sales.

- End-User Trends: The automotive, construction, and energy sectors drive significant demand for metal fabrication equipment. The growth of these end-user industries strongly correlates with the market's performance.

- M&A Activities: The number of M&A deals within the Brazilian metal fabrication equipment industry has averaged approximately xx deals per year during the historical period (2019-2024), with a projected increase to xx deals annually during the forecast period. This indicates consolidation trends and strategic expansion among key players.

Brazil Metal Fabrication Equipment Industry Industry Insights & Trends

The Brazilian metal fabrication equipment market is projected to experience robust growth during the forecast period (2025-2033), driven by the expansion of key industrial sectors and government initiatives promoting infrastructure development. Market size is estimated to reach xx Million by 2033, exhibiting a CAGR of xx%. This growth is further fueled by the rising adoption of advanced manufacturing technologies, including laser cutting, CNC machining, and 3D printing. The increasing focus on automation and efficiency improvements within the manufacturing sector is another significant growth driver. However, economic fluctuations and import/export dynamics can impact growth trajectories.

Key Markets & Segments Leading Brazil Metal Fabrication Equipment Industry

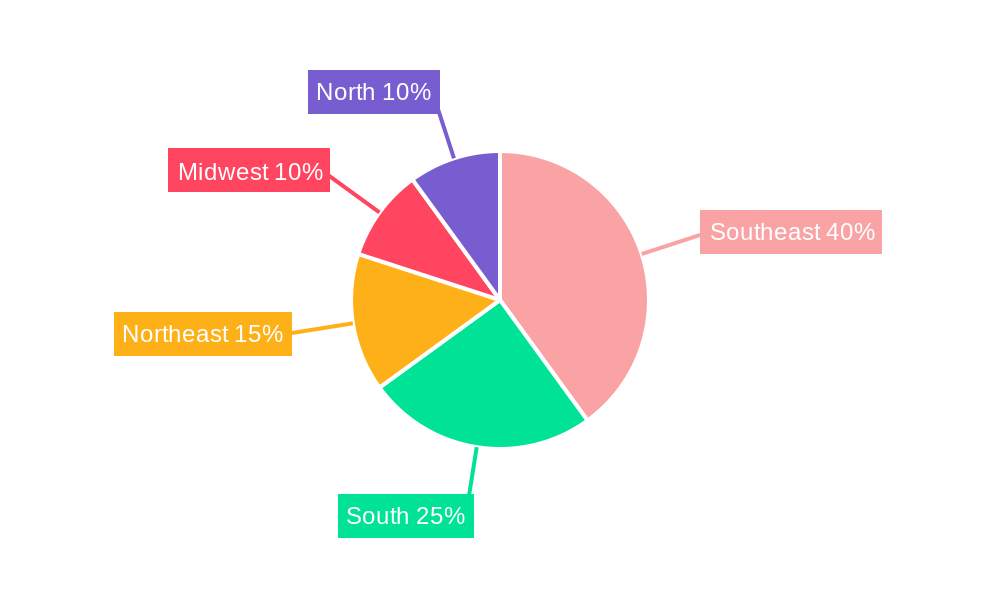

The Southeast region of Brazil dominates the metal fabrication equipment market, driven by concentrated industrial activity, a robust automotive sector, and significant infrastructure projects.

Key Drivers:

- Strong Economic Growth (Southeast Region): The region's robust economy provides a fertile ground for investments in advanced manufacturing technologies.

- Automotive Industry Expansion: The booming automotive sector fuels considerable demand for high-precision metal fabrication equipment.

- Infrastructure Development: Major infrastructure projects like road expansions and building construction increase demand for equipment.

The automotive segment stands as the largest end-user, followed by construction and energy.

Brazil Metal Fabrication Equipment Industry Product Developments

Recent product innovations focus on improved precision, automation capabilities, and enhanced safety features. Advancements in CNC technology, laser cutting systems, and robotic welding are transforming the industry. Manufacturers are increasingly incorporating Industry 4.0 principles to enhance equipment connectivity and data analytics for improved production efficiency. This contributes to a competitive edge, allowing for faster production cycles and higher quality outputs.

Challenges in the Brazil Metal Fabrication Equipment Industry Market

The Brazilian metal fabrication equipment market faces several challenges, including fluctuating currency exchange rates impacting import costs, complex import regulations, and the availability of skilled labor. Supply chain disruptions, exacerbated by global events, also present significant headwinds. The intensity of competition, particularly from international players with established market presence, further complicates the market landscape. These factors collectively limit market growth potential.

Forces Driving Brazil Metal Fabrication Equipment Industry Growth

Key drivers include the government's focus on infrastructure development, strong growth in the automotive and construction sectors, and increasing adoption of advanced manufacturing techniques. Favorable government policies supporting industrial automation and technological upgrades further propel market expansion. The rise in demand for high-precision metal components from diverse sectors sustains long-term market growth.

Long-Term Growth Catalysts in the Brazil Metal Fabrication Equipment Industry

Long-term growth will be driven by continued investment in technological advancements, strategic partnerships between domestic and international companies, and expansion into new market segments like renewable energy and aerospace. Government incentives fostering innovation and technological adoption further enhance long-term prospects.

Emerging Opportunities in Brazil Metal Fabrication Equipment Industry

Emerging opportunities lie in the adoption of additive manufacturing (3D printing), the integration of IoT (Internet of Things) into equipment, and the growing demand for customized metal fabrication solutions. Expanding into smaller manufacturing businesses and offering service contracts can also open up new revenue streams for market players.

Leading Players in the Brazil Metal Fabrication Equipment Industry Sector

- BMA Brazil

- Colfax

- DMG Mori

- Amada

- Shenyang Machine Tool

- Hurco

- Kennametal

- MAG Giddings & Lewis

- List Not Exhaustive

Key Milestones in Brazil Metal Fabrication Equipment Industry Industry

- 2020: Increased government investment in infrastructure projects stimulates demand for metal fabrication equipment.

- 2021: Several major players announce new product launches incorporating advanced technologies like robotics and automation.

- 2022: A significant M&A deal involving two key players reshapes the market's competitive dynamics.

- 2023: Rising energy costs and supply chain disruptions impact production and equipment pricing.

- 2024: Several Brazilian manufacturers adopt Industry 4.0 strategies, driving greater efficiency and competitiveness.

Strategic Outlook for Brazil Metal Fabrication Equipment Industry Market

The Brazilian metal fabrication equipment market presents a promising outlook, with sustained growth expected over the forecast period driven by industrial expansion and technological advancements. Strategic partnerships, investments in R&D, and a strong focus on customer service will be crucial for success. Capitalizing on emerging technologies like additive manufacturing and embracing sustainable manufacturing practices will be key differentiators in this competitive landscape.

Brazil Metal Fabrication Equipment Industry Segmentation

-

1. Product type

- 1.1. Automatic

- 1.2. Semi - automatic

- 1.3. Manual

-

2. Equipment type

- 2.1. Cutting

- 2.2. Machining

- 2.3. Forming

- 2.4. Welding

- 2.5. Other Equipment Types

-

3. End User industry

- 3.1. Oil and Gas

- 3.2. Manufacturing

- 3.3. Power and Utilities

- 3.4. Construction

- 3.5. Other End-user Industries

Brazil Metal Fabrication Equipment Industry Segmentation By Geography

- 1. Brazil

Brazil Metal Fabrication Equipment Industry Regional Market Share

Geographic Coverage of Brazil Metal Fabrication Equipment Industry

Brazil Metal Fabrication Equipment Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 2.86% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 3.4.1. Manufacturing sector promises a greater boom in the region for the metal fabrication equipment market

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Brazil Metal Fabrication Equipment Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Product type

- 5.1.1. Automatic

- 5.1.2. Semi - automatic

- 5.1.3. Manual

- 5.2. Market Analysis, Insights and Forecast - by Equipment type

- 5.2.1. Cutting

- 5.2.2. Machining

- 5.2.3. Forming

- 5.2.4. Welding

- 5.2.5. Other Equipment Types

- 5.3. Market Analysis, Insights and Forecast - by End User industry

- 5.3.1. Oil and Gas

- 5.3.2. Manufacturing

- 5.3.3. Power and Utilities

- 5.3.4. Construction

- 5.3.5. Other End-user Industries

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. Brazil

- 5.1. Market Analysis, Insights and Forecast - by Product type

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 BMA Brazil

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Colfax

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 DMG Mori

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Amada

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 Shenyang Machine Tool

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Hurco

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 Kennametal

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 MAG Giddings & Lewis*List Not Exhaustive

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.1 BMA Brazil

List of Figures

- Figure 1: Brazil Metal Fabrication Equipment Industry Revenue Breakdown (billion, %) by Product 2025 & 2033

- Figure 2: Brazil Metal Fabrication Equipment Industry Share (%) by Company 2025

List of Tables

- Table 1: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by Product type 2020 & 2033

- Table 2: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by Equipment type 2020 & 2033

- Table 3: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by End User industry 2020 & 2033

- Table 4: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by Region 2020 & 2033

- Table 5: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by Product type 2020 & 2033

- Table 6: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by Equipment type 2020 & 2033

- Table 7: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by End User industry 2020 & 2033

- Table 8: Brazil Metal Fabrication Equipment Industry Revenue billion Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Brazil Metal Fabrication Equipment Industry?

The projected CAGR is approximately 2.86%.

2. Which companies are prominent players in the Brazil Metal Fabrication Equipment Industry?

Key companies in the market include BMA Brazil, Colfax, DMG Mori, Amada, Shenyang Machine Tool, Hurco, Kennametal, MAG Giddings & Lewis*List Not Exhaustive.

3. What are the main segments of the Brazil Metal Fabrication Equipment Industry?

The market segments include Product type, Equipment type, End User industry.

4. Can you provide details about the market size?

The market size is estimated to be USD 1.3 billion as of 2022.

5. What are some drivers contributing to market growth?

N/A

6. What are the notable trends driving market growth?

Manufacturing sector promises a greater boom in the region for the metal fabrication equipment market.

7. Are there any restraints impacting market growth?

N/A

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in billion.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Brazil Metal Fabrication Equipment Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Brazil Metal Fabrication Equipment Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Brazil Metal Fabrication Equipment Industry?

To stay informed about further developments, trends, and reports in the Brazil Metal Fabrication Equipment Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

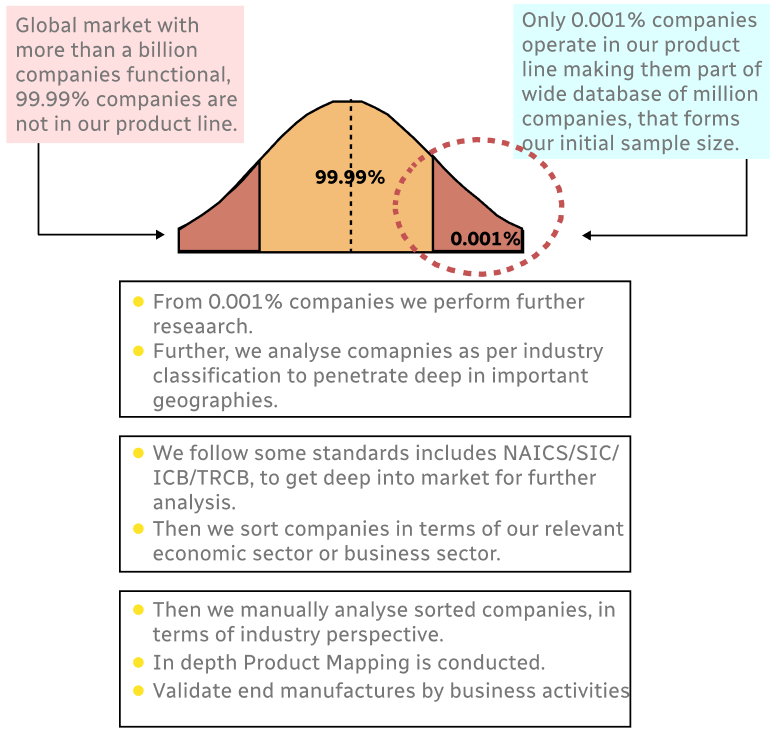

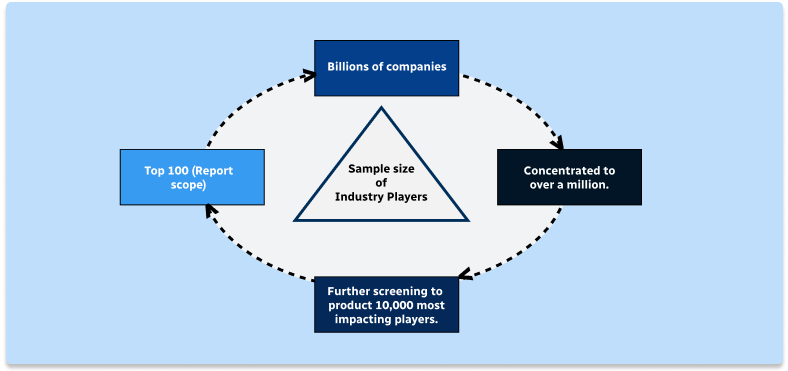

Step 1 - Identification of Relevant Samples Size from Population Database

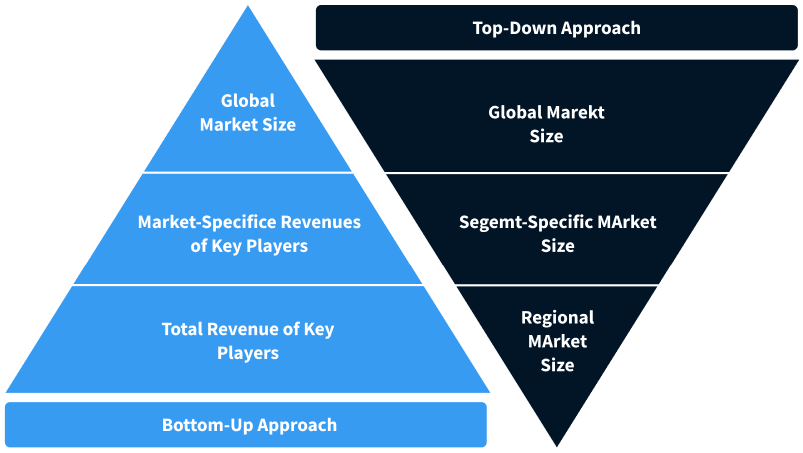

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

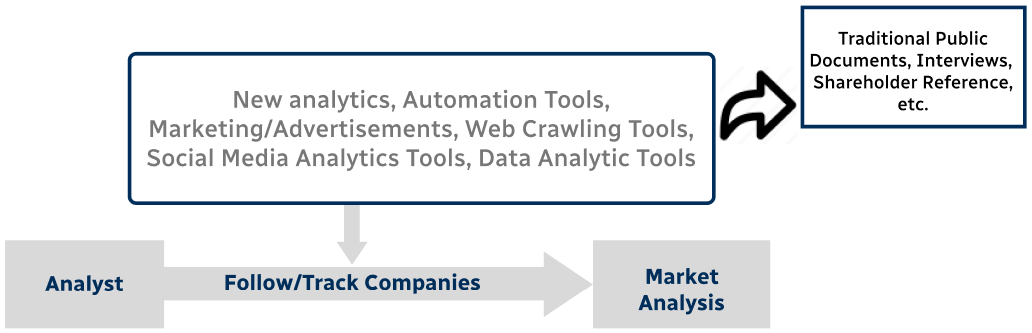

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence