Key Insights

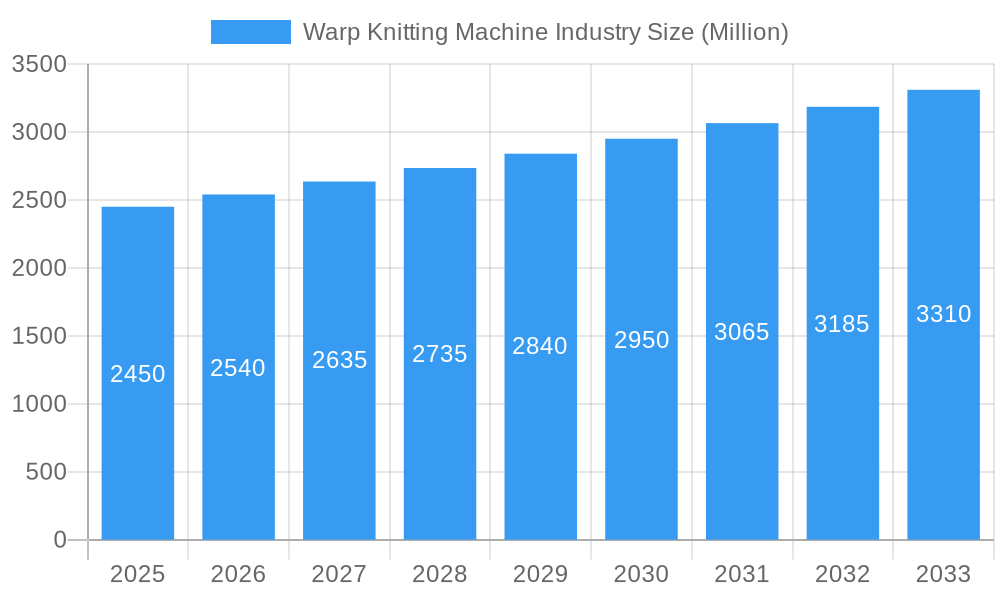

The global warp knitting machine market is projected to reach a substantial valuation, driven by consistent demand from diverse application sectors and technological advancements. With a Compound Annual Growth Rate (CAGR) of 3.70% from 2025 to 2033, the market's expansion is underpinned by the increasing adoption of warp knitted fabrics in apparel, home textiles, and crucially, technical textiles. The apparel sector, a perennial driver, benefits from warp knitting's ability to produce versatile, high-performance fabrics for activewear, athleisure, and fashion. Home textiles are also seeing growth, with warp knitted materials contributing to bedding, upholstery, and curtains due to their durability and aesthetic appeal. Emerging applications in technical textiles, such as geotextiles, medical fabrics, and automotive interiors, represent significant growth avenues. These specialized applications demand fabrics with specific properties like strength, elasticity, and breathability, all of which can be achieved through advanced warp knitting technologies. The market's robust growth trajectory is further supported by ongoing innovation in machine efficiency, automation, and the development of new knitting structures, enabling manufacturers to meet evolving consumer and industrial needs.

Warp Knitting Machine Industry Market Size (In Billion)

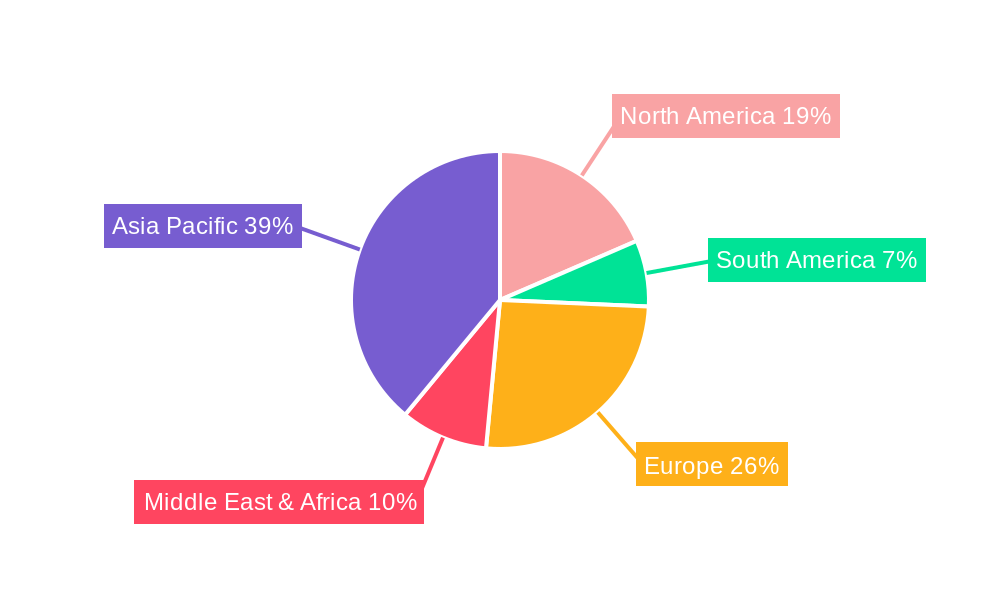

The market landscape is characterized by a dynamic interplay of growth drivers and restraining factors. Key drivers include the rising disposable incomes globally, leading to increased spending on textiles for both fashion and home furnishings, and the growing emphasis on sustainable and eco-friendly textile production, where warp knitting can offer advantages in terms of reduced waste and energy consumption. The technical textiles segment, in particular, is a potent growth engine, propelled by advancements in materials science and the demand for specialized fabrics in industries like automotive, medical, and construction. However, the market faces certain restraints, including the high initial investment cost of sophisticated warp knitting machinery and the volatility in raw material prices, which can impact manufacturing costs. Geographically, Asia Pacific, particularly China and India, is expected to dominate the market due to its strong manufacturing base and burgeoning domestic demand. Europe and North America, while mature markets, continue to be significant due to their focus on high-value, technical textiles and innovation. The competitive landscape features established players like Karl Mayer and Jakob Muller AG, alongside emerging regional manufacturers, all striving to capture market share through product innovation and strategic partnerships.

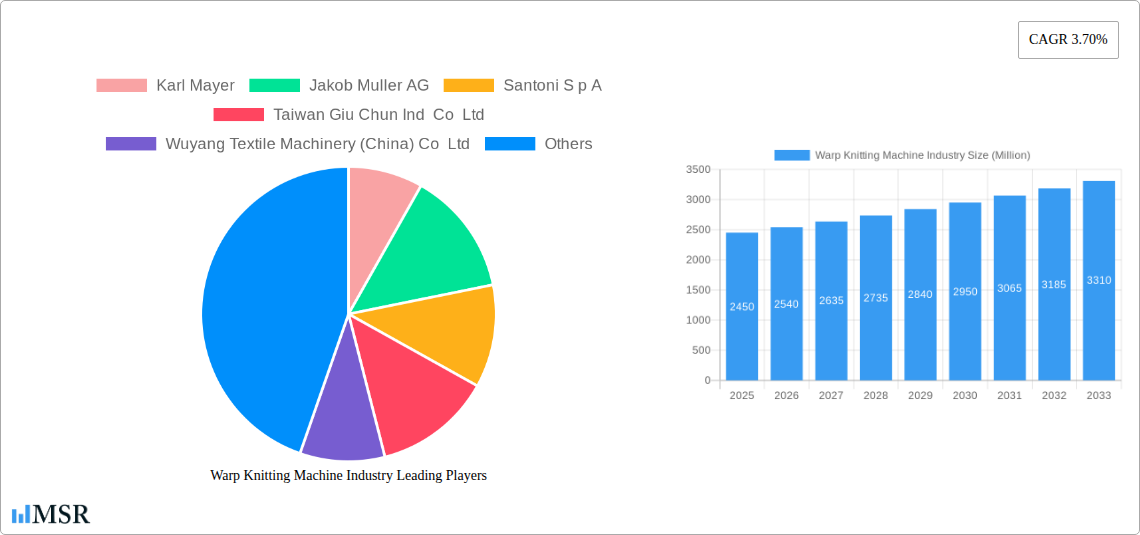

Warp Knitting Machine Industry Company Market Share

Dive deep into the global warp knitting machine market with our definitive report, meticulously crafted for industry leaders, manufacturers, investors, and researchers. This in-depth analysis provides unparalleled insights into the dynamics, trends, and future trajectory of this vital sector, covering the period from 2019–2033, with a base and estimated year of 2025, and a forecast period of 2025–2033.

Warp Knitting Machine Industry Market Concentration & Dynamics

The warp knitting machine market exhibits a moderate to high concentration, dominated by a few key global players while also featuring a growing number of specialized manufacturers. The innovation ecosystem is robust, driven by constant R&D investments in automation, digitalization, and specialized machine functionalities. Regulatory frameworks, primarily focused on safety, environmental standards, and fair trade practices, are evolving to accommodate technological advancements. The threat of substitute products is relatively low, given the unique capabilities of warp knitting for specific textile structures. End-user trends are heavily influencing machine development, with a surging demand for high-performance fabrics in technical and industrial applications. Merger and acquisition (M&A) activities, while not at an explosive pace, are strategically focused on expanding product portfolios and market reach. We anticipate approximately 3-5 significant M&A deals annually within the broader textile machinery sector, impacting the warp knitting segment. The global market size for warp knitting machines is projected to reach XX Billion by 2025, with an estimated market share dominated by Karl Mayer holding approximately 35-40%.

Warp Knitting Machine Industry Industry Insights & Trends

The warp knitting machine industry is on an upward trajectory, propelled by a confluence of factors driving market growth. The estimated market size for warp knitting machines is projected to be XX Billion USD in 2025, with an anticipated Compound Annual Growth Rate (CAGR) of XX% during the forecast period of 2025-2033. This growth is underpinned by the increasing demand for lightweight, durable, and high-performance textiles across diverse applications. Technological disruptions are at the forefront, with advancements in digital control systems, AI-powered pattern design, and energy-efficient machinery significantly enhancing productivity and fabric quality. The integration of IoT and Industry 4.0 principles allows for real-time monitoring, predictive maintenance, and optimized production workflows, thereby reducing operational costs for manufacturers. Evolving consumer behaviors are also playing a crucial role; the growing preference for sustainable and ethically produced textiles is pushing manufacturers to adopt eco-friendly production methods, which in turn influences the demand for warp knitting machines capable of processing recycled and biodegradable yarns. Furthermore, the expansion of the e-commerce landscape for fashion and home goods has amplified the need for agile and responsive textile manufacturing, a niche that warp knitting machines are adept at fulfilling. The increasing utilization of warp-knitted fabrics in the automotive sector for interior components, airbags, and lightweight structural elements, alongside their established presence in apparel and home furnishings, further solidifies the market's growth prospects. Innovations in 3D warp knitting are also opening new avenues for producing seamless, integrated textile structures with advanced functionalities. The global market is expected to reach approximately XX Billion USD by 2033.

Key Markets & Segments Leading Warp Knitting Machine Industry

The global warp knitting machine market is characterized by dynamic regional dominance and segment leadership. Geographically, Asia-Pacific stands out as the leading region, driven by robust manufacturing capabilities, significant investments in textile infrastructure, and a vast domestic market for apparel and technical textiles. Countries like China and India are at the forefront, contributing significantly to both production and consumption.

- Dominant Regions & Countries:

- Asia-Pacific: Account for over XX% of the global market share, fueled by strong economic growth, favorable manufacturing policies, and substantial demand for textiles.

- Europe: A key market for high-end, specialized warp knitting machines, particularly for technical textiles and automotive applications, with countries like Germany leading in innovation.

- North America: Growing demand for technical textiles and sustainable apparel is driving market expansion.

Within machine types, Raschel Knit machines are experiencing significant traction due to their versatility in producing a wide array of fabrics, from fine laces to heavy-duty nets and composites.

- Machine Type Dominance:

- Raschel Knit: Expected to capture a market share of approximately XX% by 2025, driven by applications in sportswear, medical textiles, and industrial filters.

- Tricot Knit: Continues to hold a substantial share, essential for apparel linings, swimwear, and lingerie.

- Milanese Knit: Showing strong growth in niche markets requiring dense, stable fabrics for high-performance apparel.

The application segment witnessing the most rapid expansion is Technical Textiles, where warp knitting excels in creating functional fabrics for diverse industries.

- Application Segment Leadership:

- Technical Textiles: Projected to grow at a CAGR of XX%, encompassing automotive interiors, geotextiles, medical implants, protective clothing, and filtration media.

- Apparel Textiles: Remains a core segment, with increasing demand for innovative textures and performance features.

- Home Textiles: Steady growth, particularly in areas like bedding, upholstery, and curtains requiring specialized textures and durability.

The growth in these segments is directly linked to macro-economic factors such as rising disposable incomes, increased urbanization, and a growing emphasis on specialized functional materials across industries. The infrastructure development in emerging economies further bolsters the demand for warp knitting machines in the technical textile sector.

Warp Knitting Machine Industry Product Developments

Warp knitting machine manufacturers are consistently innovating to meet evolving industry demands. Recent product developments focus on enhanced automation, increased speed, energy efficiency, and the capability to produce complex fabric structures with greater precision. Innovations include advanced digital pattern control for intricate designs, integrated quality control systems for real-time defect detection, and the development of machines capable of processing a wider range of yarn types, including sustainable and recycled fibers. The market relevance of these developments lies in their ability to empower manufacturers to produce higher-value, specialized textiles for demanding applications in apparel, home furnishings, and particularly, technical textiles such as automotive components, medical devices, and industrial filters. The competitive edge derived from these advancements allows companies to cater to niche markets and maintain profitability in an increasingly competitive landscape.

Challenges in the Warp Knitting Machine Industry Market

The warp knitting machine market faces several significant challenges. High initial capital investment for advanced machinery acts as a barrier for smaller manufacturers. Stringent environmental regulations and the increasing demand for sustainable production processes necessitate costly upgrades and adoption of new technologies. Furthermore, supply chain disruptions, exacerbated by geopolitical factors and raw material price volatility, can impact production timelines and costs. Skilled labor shortages for operating and maintaining sophisticated warp knitting machinery also pose a considerable constraint. The competitive pressure from lower-cost manufacturing regions can also impact profit margins for established players. Quantifiable impacts include potential delays in adoption of new technologies by up to 15-20% for SMEs due to capital constraints and an estimated 5-10% increase in operational costs due to supply chain volatility.

Forces Driving Warp Knitting Machine Industry Growth

Several key forces are propelling the growth of the warp knitting machine industry. Technological advancements, particularly in digitalization and automation, are enhancing efficiency and enabling the production of complex, high-value textiles. The expanding applications of warp-knitted fabrics in the technical textiles sector, including automotive, medical, and industrial applications, are significant growth drivers. Increasing global demand for sustainable and eco-friendly textile solutions is also encouraging innovation and adoption of warp knitting technologies capable of processing recycled and biodegradable materials. Economic growth in emerging markets is leading to increased disposable incomes and a subsequent rise in demand for sophisticated apparel and home textiles, further boosting the sector.

Challenges in the Warp Knitting Machine Industry Market

While growth is evident, the warp knitting machine industry must navigate long-term challenges to ensure sustained expansion. The continuous need for R&D investment to stay ahead of technological curves is substantial. Adapting to evolving sustainability mandates and consumer expectations for eco-conscious production requires ongoing innovation and potentially significant capital expenditure. Furthermore, maintaining a competitive edge against rapidly advancing technologies and potential disruptive innovations from adjacent industries demands strategic foresight and agile business models. The global nature of the market also necessitates navigating diverse regulatory landscapes and geopolitical uncertainties, which can impact international trade and investment.

Emerging Opportunities in Warp Knitting Machine Industry

The warp knitting machine industry is ripe with emerging opportunities. The burgeoning demand for technical textiles in sectors like aerospace, renewable energy (e.g., wind turbine components), and advanced construction presents vast untapped potential. The rise of 3D knitting technology offers exciting prospects for creating seamless, functional garments and complex composite structures with reduced waste. Increased focus on circular economy principles is creating opportunities for machines designed to process recycled fibers and for textile recycling technologies that complement warp knitting. Furthermore, the growing interest in personalized and on-demand manufacturing in the apparel sector opens avenues for highly flexible and adaptable warp knitting solutions. The digitalization of the textile value chain presents opportunities for developing integrated software solutions and smart machinery that enhance connectivity and data-driven decision-making.

Leading Players in the Warp Knitting Machine Industry Sector

- Karl Mayer

- Jakob Muller AG

- Santoni S p A

- Taiwan Giu Chun Ind Co Ltd

- Wuyang Textile Machinery (China) Co Ltd

- Changzhou Runyuan Warp Knitting Machinery Co Ltd

- COMEZ

- Jingwei textile machinery

- Ruanyuan

- Terrot GmbH

- Dukoo Machinery Industry Co

Key Milestones in Warp Knitting Machine Industry Industry

- May 2022: KM.ON innovates and digitalizes the textile value chain with its offerings. The software company of the KARL MAYER Group is continuously developing new digital solutions to improve the customer experience, reduce complexity in our customers' day-to-day business and ultimately make their business more profitable.

- December 2021: Three new products of Wuyang Textile Machinery passed the appraisal of scientific and technological achievements which includes "GE288/5 intelligent cashmere double needle bed warp knitting machine" and " GE2290 jacquard warp knitting machine" and "SMJ- CNC Mesh Fabric Warp Knitting Machine."

Strategic Outlook for Warp Knitting Machine Industry Market

The strategic outlook for the warp knitting machine market is characterized by sustained growth and significant opportunities for innovation. Key growth accelerators include the continued expansion of technical textile applications, the increasing adoption of digitalization and automation across the value chain, and the growing consumer demand for sustainable and high-performance fabrics. Manufacturers that invest in R&D, focus on developing energy-efficient and eco-friendly solutions, and adapt to the evolving needs of diverse end-user industries will be best positioned for success. Strategic collaborations and partnerships will be crucial for navigating market complexities and tapping into new technological frontiers. The market is set to witness further advancements in intelligent machinery and integrated manufacturing solutions, driving efficiency and profitability for stakeholders.

Warp Knitting Machine Industry Segmentation

-

1. Machine Type

- 1.1. Tricot Knit

- 1.2. Raschel Knit

- 1.3. Crochet Knit

- 1.4. Milanese Knit

-

2. Application

- 2.1. Apparel Textiles

- 2.2. Home Textiles

- 2.3. Technical Textiles

- 2.4. Automotive Textiles

- 2.5. Others

Warp Knitting Machine Industry Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Mexico

-

2. South America

- 2.1. Brazil

- 2.2. Argentina

- 2.3. Rest of South America

-

3. Europe

- 3.1. United Kingdom

- 3.2. Germany

- 3.3. France

- 3.4. Italy

- 3.5. Spain

- 3.6. Russia

- 3.7. Benelux

- 3.8. Nordics

- 3.9. Rest of Europe

-

4. Middle East & Africa

- 4.1. Turkey

- 4.2. Israel

- 4.3. GCC

- 4.4. North Africa

- 4.5. South Africa

- 4.6. Rest of Middle East & Africa

-

5. Asia Pacific

- 5.1. China

- 5.2. India

- 5.3. Japan

- 5.4. South Korea

- 5.5. ASEAN

- 5.6. Oceania

- 5.7. Rest of Asia Pacific

Warp Knitting Machine Industry Regional Market Share

Geographic Coverage of Warp Knitting Machine Industry

Warp Knitting Machine Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 9.36% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 3.4.1. Sports Footwear Creating Demand

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Warp Knitting Machine Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Machine Type

- 5.1.1. Tricot Knit

- 5.1.2. Raschel Knit

- 5.1.3. Crochet Knit

- 5.1.4. Milanese Knit

- 5.2. Market Analysis, Insights and Forecast - by Application

- 5.2.1. Apparel Textiles

- 5.2.2. Home Textiles

- 5.2.3. Technical Textiles

- 5.2.4. Automotive Textiles

- 5.2.5. Others

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. South America

- 5.3.3. Europe

- 5.3.4. Middle East & Africa

- 5.3.5. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Machine Type

- 6. North America Warp Knitting Machine Industry Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Machine Type

- 6.1.1. Tricot Knit

- 6.1.2. Raschel Knit

- 6.1.3. Crochet Knit

- 6.1.4. Milanese Knit

- 6.2. Market Analysis, Insights and Forecast - by Application

- 6.2.1. Apparel Textiles

- 6.2.2. Home Textiles

- 6.2.3. Technical Textiles

- 6.2.4. Automotive Textiles

- 6.2.5. Others

- 6.1. Market Analysis, Insights and Forecast - by Machine Type

- 7. South America Warp Knitting Machine Industry Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Machine Type

- 7.1.1. Tricot Knit

- 7.1.2. Raschel Knit

- 7.1.3. Crochet Knit

- 7.1.4. Milanese Knit

- 7.2. Market Analysis, Insights and Forecast - by Application

- 7.2.1. Apparel Textiles

- 7.2.2. Home Textiles

- 7.2.3. Technical Textiles

- 7.2.4. Automotive Textiles

- 7.2.5. Others

- 7.1. Market Analysis, Insights and Forecast - by Machine Type

- 8. Europe Warp Knitting Machine Industry Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Machine Type

- 8.1.1. Tricot Knit

- 8.1.2. Raschel Knit

- 8.1.3. Crochet Knit

- 8.1.4. Milanese Knit

- 8.2. Market Analysis, Insights and Forecast - by Application

- 8.2.1. Apparel Textiles

- 8.2.2. Home Textiles

- 8.2.3. Technical Textiles

- 8.2.4. Automotive Textiles

- 8.2.5. Others

- 8.1. Market Analysis, Insights and Forecast - by Machine Type

- 9. Middle East & Africa Warp Knitting Machine Industry Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Machine Type

- 9.1.1. Tricot Knit

- 9.1.2. Raschel Knit

- 9.1.3. Crochet Knit

- 9.1.4. Milanese Knit

- 9.2. Market Analysis, Insights and Forecast - by Application

- 9.2.1. Apparel Textiles

- 9.2.2. Home Textiles

- 9.2.3. Technical Textiles

- 9.2.4. Automotive Textiles

- 9.2.5. Others

- 9.1. Market Analysis, Insights and Forecast - by Machine Type

- 10. Asia Pacific Warp Knitting Machine Industry Analysis, Insights and Forecast, 2020-2032

- 10.1. Market Analysis, Insights and Forecast - by Machine Type

- 10.1.1. Tricot Knit

- 10.1.2. Raschel Knit

- 10.1.3. Crochet Knit

- 10.1.4. Milanese Knit

- 10.2. Market Analysis, Insights and Forecast - by Application

- 10.2.1. Apparel Textiles

- 10.2.2. Home Textiles

- 10.2.3. Technical Textiles

- 10.2.4. Automotive Textiles

- 10.2.5. Others

- 10.1. Market Analysis, Insights and Forecast - by Machine Type

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2025

- 11.2. Company Profiles

- 11.2.1 Karl Mayer

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Jakob Muller AG

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 Santoni S p A

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 Taiwan Giu Chun Ind Co Ltd

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 Wuyang Textile Machinery (China) Co Ltd

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 Changzhou Runyuan Warp Knitting Machinery Co Ltd

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 COMEZ

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 Jingwei textile machinery

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 Ruanyuan

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Terrot GmbH

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 Dukoo Machinery Industry Co *List Not Exhaustive 6 3 Other Companies (Overview/Key Information

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.1 Karl Mayer

List of Figures

- Figure 1: Global Warp Knitting Machine Industry Revenue Breakdown (undefined, %) by Region 2025 & 2033

- Figure 2: North America Warp Knitting Machine Industry Revenue (undefined), by Machine Type 2025 & 2033

- Figure 3: North America Warp Knitting Machine Industry Revenue Share (%), by Machine Type 2025 & 2033

- Figure 4: North America Warp Knitting Machine Industry Revenue (undefined), by Application 2025 & 2033

- Figure 5: North America Warp Knitting Machine Industry Revenue Share (%), by Application 2025 & 2033

- Figure 6: North America Warp Knitting Machine Industry Revenue (undefined), by Country 2025 & 2033

- Figure 7: North America Warp Knitting Machine Industry Revenue Share (%), by Country 2025 & 2033

- Figure 8: South America Warp Knitting Machine Industry Revenue (undefined), by Machine Type 2025 & 2033

- Figure 9: South America Warp Knitting Machine Industry Revenue Share (%), by Machine Type 2025 & 2033

- Figure 10: South America Warp Knitting Machine Industry Revenue (undefined), by Application 2025 & 2033

- Figure 11: South America Warp Knitting Machine Industry Revenue Share (%), by Application 2025 & 2033

- Figure 12: South America Warp Knitting Machine Industry Revenue (undefined), by Country 2025 & 2033

- Figure 13: South America Warp Knitting Machine Industry Revenue Share (%), by Country 2025 & 2033

- Figure 14: Europe Warp Knitting Machine Industry Revenue (undefined), by Machine Type 2025 & 2033

- Figure 15: Europe Warp Knitting Machine Industry Revenue Share (%), by Machine Type 2025 & 2033

- Figure 16: Europe Warp Knitting Machine Industry Revenue (undefined), by Application 2025 & 2033

- Figure 17: Europe Warp Knitting Machine Industry Revenue Share (%), by Application 2025 & 2033

- Figure 18: Europe Warp Knitting Machine Industry Revenue (undefined), by Country 2025 & 2033

- Figure 19: Europe Warp Knitting Machine Industry Revenue Share (%), by Country 2025 & 2033

- Figure 20: Middle East & Africa Warp Knitting Machine Industry Revenue (undefined), by Machine Type 2025 & 2033

- Figure 21: Middle East & Africa Warp Knitting Machine Industry Revenue Share (%), by Machine Type 2025 & 2033

- Figure 22: Middle East & Africa Warp Knitting Machine Industry Revenue (undefined), by Application 2025 & 2033

- Figure 23: Middle East & Africa Warp Knitting Machine Industry Revenue Share (%), by Application 2025 & 2033

- Figure 24: Middle East & Africa Warp Knitting Machine Industry Revenue (undefined), by Country 2025 & 2033

- Figure 25: Middle East & Africa Warp Knitting Machine Industry Revenue Share (%), by Country 2025 & 2033

- Figure 26: Asia Pacific Warp Knitting Machine Industry Revenue (undefined), by Machine Type 2025 & 2033

- Figure 27: Asia Pacific Warp Knitting Machine Industry Revenue Share (%), by Machine Type 2025 & 2033

- Figure 28: Asia Pacific Warp Knitting Machine Industry Revenue (undefined), by Application 2025 & 2033

- Figure 29: Asia Pacific Warp Knitting Machine Industry Revenue Share (%), by Application 2025 & 2033

- Figure 30: Asia Pacific Warp Knitting Machine Industry Revenue (undefined), by Country 2025 & 2033

- Figure 31: Asia Pacific Warp Knitting Machine Industry Revenue Share (%), by Country 2025 & 2033

List of Tables

- Table 1: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Machine Type 2020 & 2033

- Table 2: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 3: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Region 2020 & 2033

- Table 4: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Machine Type 2020 & 2033

- Table 5: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 6: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 7: United States Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 8: Canada Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 9: Mexico Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 10: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Machine Type 2020 & 2033

- Table 11: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 12: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 13: Brazil Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 14: Argentina Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 15: Rest of South America Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 16: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Machine Type 2020 & 2033

- Table 17: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 18: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 19: United Kingdom Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 20: Germany Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 21: France Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 22: Italy Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 23: Spain Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 24: Russia Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 25: Benelux Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 26: Nordics Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 27: Rest of Europe Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 28: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Machine Type 2020 & 2033

- Table 29: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 30: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 31: Turkey Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 32: Israel Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 33: GCC Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 34: North Africa Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 35: South Africa Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 36: Rest of Middle East & Africa Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 37: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Machine Type 2020 & 2033

- Table 38: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 39: Global Warp Knitting Machine Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 40: China Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 41: India Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 42: Japan Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 43: South Korea Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 44: ASEAN Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 45: Oceania Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 46: Rest of Asia Pacific Warp Knitting Machine Industry Revenue (undefined) Forecast, by Application 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Warp Knitting Machine Industry?

The projected CAGR is approximately 9.36%.

2. Which companies are prominent players in the Warp Knitting Machine Industry?

Key companies in the market include Karl Mayer, Jakob Muller AG, Santoni S p A, Taiwan Giu Chun Ind Co Ltd, Wuyang Textile Machinery (China) Co Ltd, Changzhou Runyuan Warp Knitting Machinery Co Ltd, COMEZ, Jingwei textile machinery, Ruanyuan, Terrot GmbH, Dukoo Machinery Industry Co *List Not Exhaustive 6 3 Other Companies (Overview/Key Information.

3. What are the main segments of the Warp Knitting Machine Industry?

The market segments include Machine Type, Application.

4. Can you provide details about the market size?

The market size is estimated to be USD XXX N/A as of 2022.

5. What are some drivers contributing to market growth?

N/A

6. What are the notable trends driving market growth?

Sports Footwear Creating Demand.

7. Are there any restraints impacting market growth?

N/A

8. Can you provide examples of recent developments in the market?

May 2022: KM.ON innovates and digitalizes the textile value chain with its offerings. The software company of the KARL MAYER Group is continuously developing new digital solutions to improve the customer experience, reduce complexity in our customers' day-to-day business and ultimately make their business more profitable.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in N/A.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Warp Knitting Machine Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Warp Knitting Machine Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Warp Knitting Machine Industry?

To stay informed about further developments, trends, and reports in the Warp Knitting Machine Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

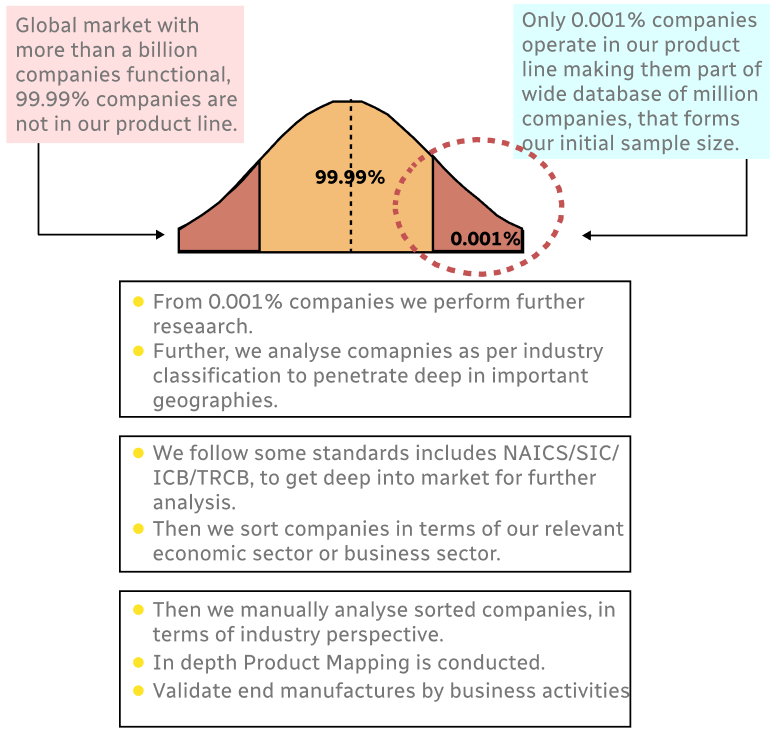

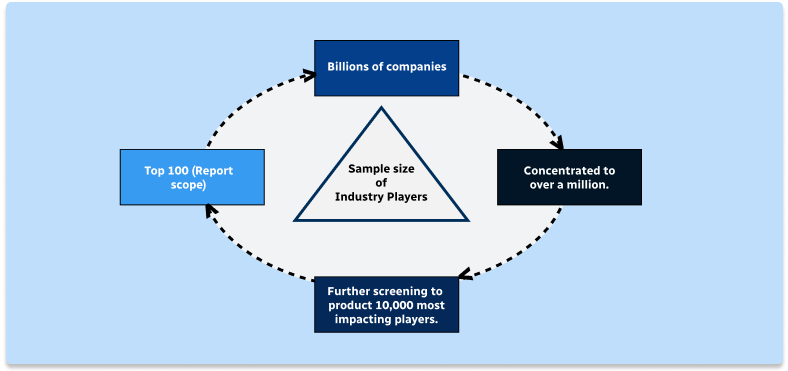

Step 1 - Identification of Relevant Samples Size from Population Database

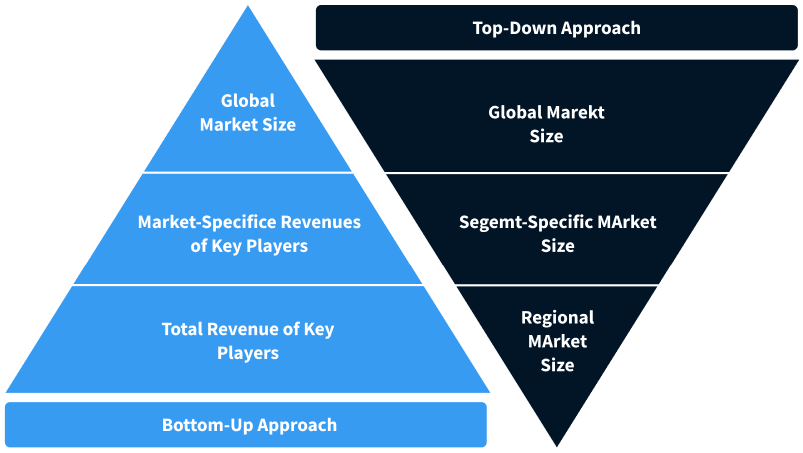

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

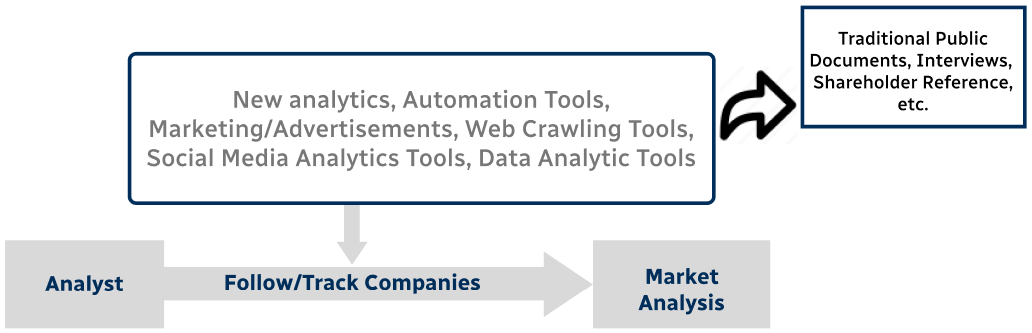

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence