Key Insights

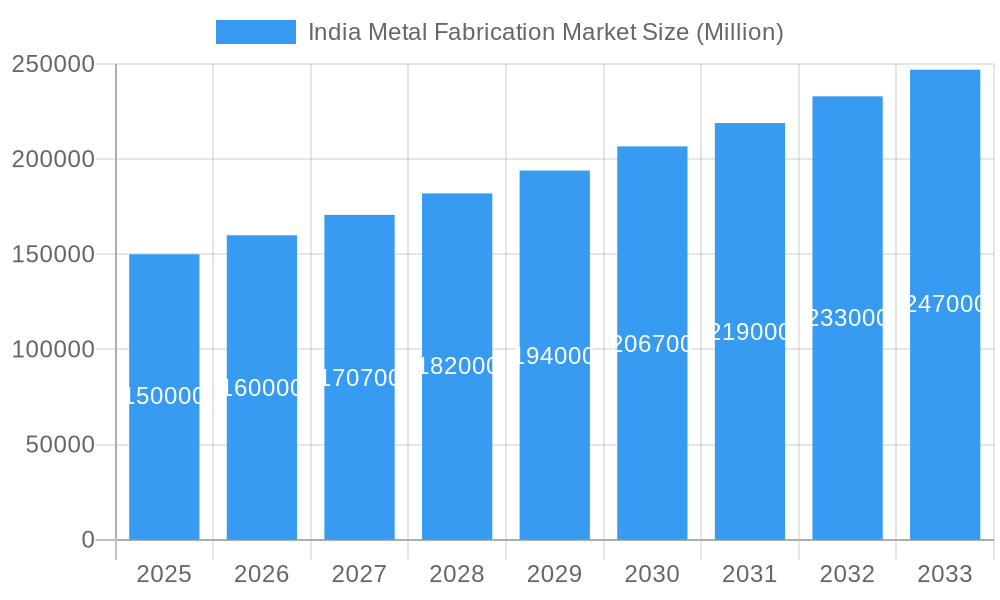

The India Metal Fabrication Market, projected at $2.91 billion in the base year 2025, is poised for substantial expansion. With an anticipated Compound Annual Growth Rate (CAGR) of 5.27%, the market is expected to reach significant valuations by 2033. This growth is primarily propelled by the robust performance of the construction and infrastructure sectors, coupled with rising demand in the automotive and consumer durables industries. Government initiatives like "Make in India" and a broader focus on industrial development are further accelerating market momentum. Key trends, including the adoption of automation and advanced fabrication technologies, are enhancing efficiency and precision. While challenges such as raw material price volatility and skilled labor availability persist, the market's positive outlook is supported by India's sustained economic growth and strong industrial output. Market segmentation spans product types (structural steel, sheet metal components, pressure vessels), applications (construction, automotive, energy), and regional markets, offering diverse opportunities.

India Metal Fabrication Market Market Size (In Billion)

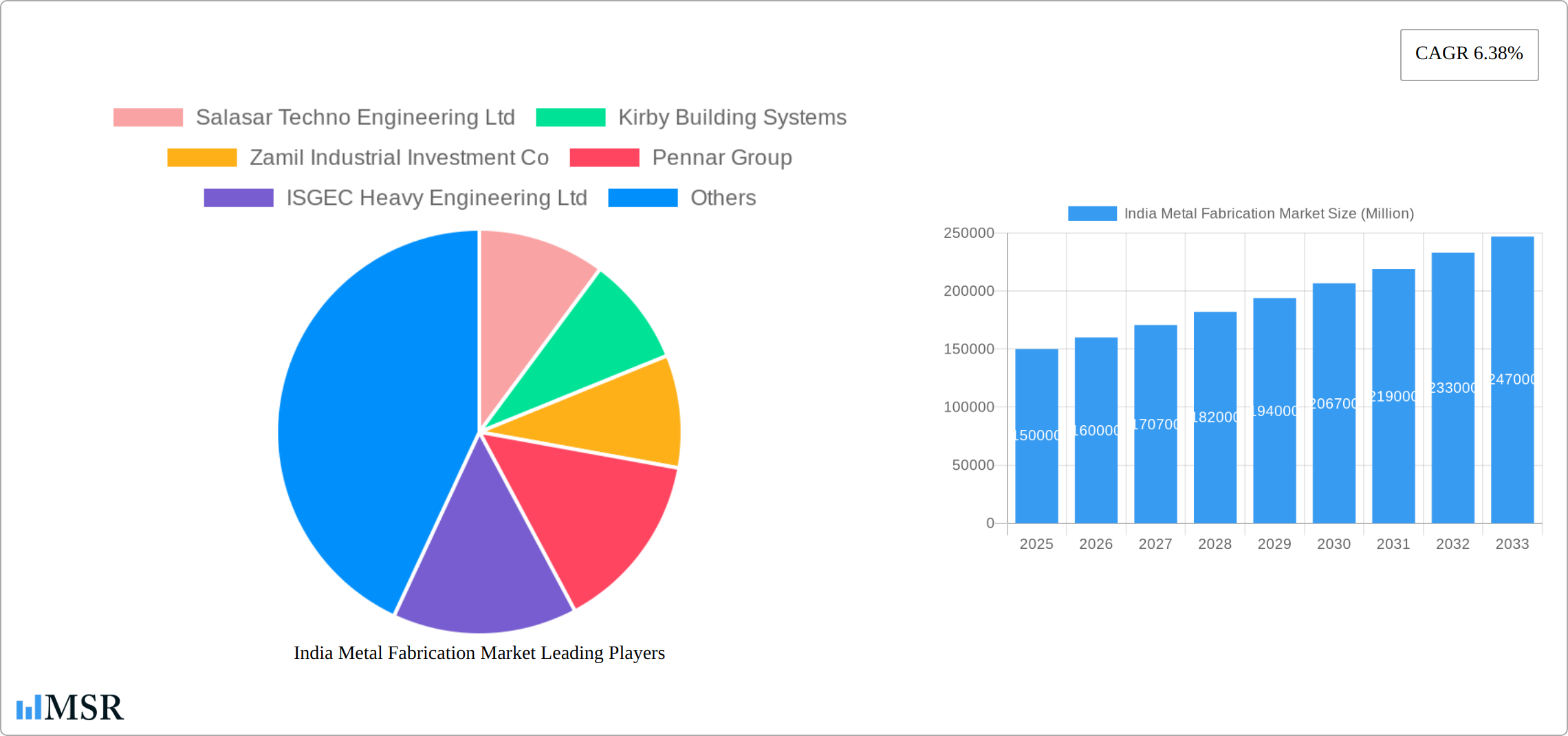

Leading entities such as Salasar Techno Engineering Ltd, Kirby Building Systems, and Larsen & Toubro Ltd are instrumental in shaping the competitive landscape. The presence of a dynamic ecosystem of smaller enterprises and emerging businesses underscores the market's vitality. Future success will depend on strategic adoption of cutting-edge technologies, production process optimization, and adeptness in meeting varied industry segment demands. The forecast period from 2025 to 2033 presents compelling growth avenues, positioning the India Metal Fabrication Market as a promising investment arena for established corporations and new ventures alike.

India Metal Fabrication Market Company Market Share

India Metal Fabrication Market Report: 2019-2033

This comprehensive report provides a detailed analysis of the India Metal Fabrication Market, offering invaluable insights for industry stakeholders, investors, and businesses seeking to navigate this dynamic sector. The report covers the period 2019-2033, with a focus on the forecast period 2025-2033 and a base year of 2025. Expect in-depth analysis of market size, CAGR, key segments, leading players, and emerging trends.

India Metal Fabrication Market Market Concentration & Dynamics

The India Metal Fabrication Market exhibits a moderately concentrated structure, with a few large players holding significant market share. However, a substantial number of smaller and medium-sized enterprises (SMEs) also contribute significantly to the overall market volume. Market share data for individual companies is currently unavailable, but we estimate the top five players account for approximately xx% of the market. The market's dynamics are shaped by several key factors:

- Innovation Ecosystems: The Indian metal fabrication sector is witnessing growing adoption of advanced technologies like automation, robotics, and additive manufacturing, driving efficiency and product innovation. This is fostered by collaborations between industry players, research institutions, and government initiatives.

- Regulatory Frameworks: Government policies promoting infrastructure development, "Make in India" initiatives, and favorable tax structures significantly influence market growth. However, regulatory complexities and bureaucratic hurdles can sometimes impede progress.

- Substitute Products: The market faces competition from substitute materials like plastics and composites in certain applications. However, the inherent strength and durability of metal continue to drive its demand across numerous sectors.

- End-User Trends: Growing demand from construction, automotive, energy, and manufacturing sectors fuels market expansion. Changes in consumer preferences and building codes influence the type and volume of metal fabrication required.

- M&A Activities: The market has witnessed a moderate level of mergers and acquisitions (M&A) activity in recent years, with xx major deals recorded between 2019 and 2024. This consolidation trend is expected to continue as larger players seek to expand their market share and capabilities.

India Metal Fabrication Market Industry Insights & Trends

The India Metal Fabrication Market is poised for substantial expansion in the coming years. Driven by sustained momentum in critical end-use sectors such as construction, infrastructure development, and the burgeoning automotive industry, the market is anticipated to reach significant valuation by 2033. This positive trajectory is underpinned by a confluence of factors:

- Aggressive Infrastructure Development: Ambitious government-led initiatives, including the Bharatmala Pariyojana, Gati Shakti National Master Plan, and the ongoing Smart Cities Mission, are acting as powerful catalysts, generating immense demand for a wide array of metal fabrication products. This includes structural components, bridge elements, and specialized equipment.

- Robust Automotive Sector Expansion: The dynamic Indian automotive landscape, encompassing both passenger and commercial vehicles, as well as the rapidly growing electric vehicle (EV) segment, necessitates a continuous and escalating supply of intricate metal components and assemblies.

- Accelerated Industrialization and Manufacturing: The ongoing drive towards industrialization and the expansion of manufacturing capabilities across diverse sectors, from heavy machinery to consumer goods, are creating a consistent and growing demand for precision metal fabrication services and custom parts.

- Pervasive Technological Advancements: The widespread adoption of cutting-edge manufacturing technologies, such as advanced laser cutting systems, collaborative robotic welding, automated assembly lines, and additive manufacturing (3D printing), is significantly enhancing operational efficiency, dimensional accuracy, and the ability to produce complex, customized fabrications, thereby fueling market growth.

- Evolving Sustainability Imperatives: A growing emphasis on sustainable construction practices, energy efficiency, and the utilization of environmentally responsible materials is prompting the development and implementation of greener metal fabrication processes and the creation of eco-friendly metal products.

Key Markets & Segments Leading India Metal Fabrication Market

The Indian Metal Fabrication Market exhibits significant regional and sectoral diversity. While a definitive statement on a single dominant region or segment requires more granular data, key growth drivers are evident across several areas:

- Construction Sector Dominance: This segment continues to be a primary engine of market expansion, propelled by substantial government investment in large-scale infrastructure projects and rapid urbanization. The demand for structural steel, pre-fabricated building components, roofing solutions, and other fabricated metal products remains exceptionally strong.

- Automotive Industry's Growing Influence: The accelerated growth of the automotive sector, covering two-wheelers, four-wheelers, and the burgeoning commercial vehicle segment, translates into a substantial demand for a wide range of precisely fabricated metal components, chassis parts, and body structures, significantly boosting the contribution of this sector.

- Diversified Manufacturing Demand: Across a multitude of manufacturing sub-sectors, including industrial machinery, home appliances, electronics, and capital goods, the requirement for custom-designed and precisely fabricated metal components maintains a consistent and robust level, contributing significantly to the overall market volume.

- Expanding Energy Infrastructure: The development and expansion of energy infrastructure, particularly in renewable energy sectors like solar and wind power, are spurring demand for specialized and heavy-duty metal fabrications, including towers, support structures, and equipment housing, thereby providing a strong growth impetus.

A more precise dominance analysis would necessitate a deeper dive into granular market segmentation data.

India Metal Fabrication Market Product Developments

Recent product developments in the India Metal Fabrication Market focus on improved efficiency, durability, and customization. Advances in laser cutting technologies allow for greater precision and reduced material waste. Robotic welding systems enhance productivity and consistency in fabrication processes. The growing adoption of 3D printing offers new possibilities for creating complex and customized metal components. These advancements are providing significant competitive advantages to firms that embrace them.

Challenges in the India Metal Fabrication Market Market

The India Metal Fabrication Market faces several challenges:

- Supply Chain Disruptions: Fluctuations in raw material prices (especially steel) and potential supply chain bottlenecks can impact production costs and profitability.

- Regulatory Hurdles: Navigating complex regulatory frameworks and obtaining necessary permits can be time-consuming and costly.

- Intense Competition: The market is highly competitive, with numerous players vying for market share. This necessitates continuous innovation and cost optimization to maintain a competitive edge.

- Skilled Labor Shortage: A shortage of skilled labor in welding, fabrication, and related fields can hinder growth and productivity.

Forces Driving India Metal Fabrication Market Growth

Several key factors drive the growth of the India Metal Fabrication Market:

- Government Initiatives: Government policies supporting infrastructure development and "Make in India" initiatives create significant demand.

- Economic Growth: India's steady economic growth fuels demand across various sectors, driving the need for metal fabrication products.

- Technological Advancements: Adoption of advanced manufacturing technologies enhances efficiency and productivity.

Long-Term Growth Catalysts in India Metal Fabrication Market

Long-term growth hinges on continuous innovation, strategic partnerships, and market expansion. Companies focused on R&D, automation, and developing sustainable fabrication methods will benefit greatly. Expanding into new market segments and geographic areas presents additional opportunities. Strategic alliances with technology providers and raw material suppliers are crucial for securing a competitive advantage.

Emerging Opportunities in India Metal Fabrication Market

The Indian Metal Fabrication Market is ripe with emerging opportunities, including:

- Lightweighting Solutions: A pronounced demand for lighter-weight metal components across sectors like automotive and aerospace to improve fuel efficiency and performance.

- Sustainable and Green Fabrication: A growing impetus towards environmentally conscious fabrication processes, including the use of recycled materials and energy-efficient manufacturing techniques.

- High-Value Specialized Fabrication: An increasing need for bespoke, high-precision fabricated components catering to niche and technologically advanced industries.

- Digitalization and Automation: The integration of Industry 4.0 principles, including IoT, AI, and advanced analytics, to optimize fabrication processes and supply chains.

Leading Players in the India Metal Fabrication Market Sector

- Salasar Techno Engineering Ltd

- Kirby Building Systems

- Zamil Industrial Investment Co

- Pennar Group

- ISGEC Heavy Engineering Ltd

- Godrej Process Equipment

- TEMA India

- Larsen & Toubro Ltd

- Diamond Group

- Novatech Projects (India) Private Limited

- SKV Engineering India Pvt LTD

- Karamtara Engineering Pvt Ltd

- (Numerous other key players and a long tail of smaller fabricators contribute to the market landscape)

Key Milestones in India Metal Fabrication Market Industry

- October 2023: JSP's Angul steel plant expansion plans to significantly increase steel production capacity, boosting raw material availability for the fabrication sector. Trial production commenced, with commercial production targeted for 2024.

- July 2023: The MoU between ArcelorMittal Nippon Steel India and Festo India to establish the NAMTECH institute aims to enhance skilled labor availability within the manufacturing sector, potentially addressing workforce shortages in metal fabrication.

Strategic Outlook for India Metal Fabrication Market Market

The India Metal Fabrication Market presents a compelling long-term growth outlook. Companies that proactively embrace and capitalize on technological advancements, effectively align with government infrastructure development agendas, and keenly respond to evolving end-user demands are strategically positioned for significant success. A sustained focus on innovation in materials and processes, a commitment to sustainability, and the cultivation of robust, resilient supply chain partnerships will be paramount for capturing market share and achieving enduring growth in this dynamic sector.

India Metal Fabrication Market Segmentation

-

1. End-user Industry

- 1.1. Manufacturing

- 1.2. Power and Utilities

- 1.3. Construction

- 1.4. Oil and Gas

- 1.5. Other End-user Industries

-

2. Material Type

- 2.1. Steel

- 2.2. Aluminum

- 2.3. Other Material Types

-

3. Service Type

- 3.1. Casting

- 3.2. Forging

- 3.3. Machining

- 3.4. Welding and Tubing

- 3.5. Other Services

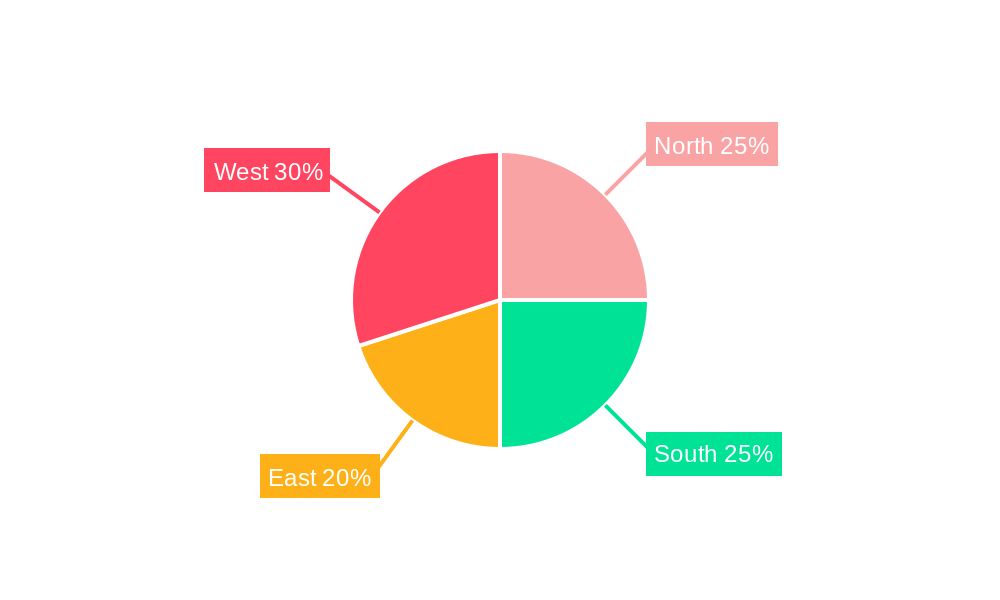

India Metal Fabrication Market Segmentation By Geography

- 1. India

India Metal Fabrication Market Regional Market Share

Geographic Coverage of India Metal Fabrication Market

India Metal Fabrication Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 5.27% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Growing Demand for Fabricated Metal Products Driving the Market; Technological Advancements Driving the Market

- 3.3. Market Restrains

- 3.3.1. Growing Demand for Fabricated Metal Products Driving the Market; Technological Advancements Driving the Market

- 3.4. Market Trends

- 3.4.1. Manufacturing Sector is Shaping the Market

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. India Metal Fabrication Market Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by End-user Industry

- 5.1.1. Manufacturing

- 5.1.2. Power and Utilities

- 5.1.3. Construction

- 5.1.4. Oil and Gas

- 5.1.5. Other End-user Industries

- 5.2. Market Analysis, Insights and Forecast - by Material Type

- 5.2.1. Steel

- 5.2.2. Aluminum

- 5.2.3. Other Material Types

- 5.3. Market Analysis, Insights and Forecast - by Service Type

- 5.3.1. Casting

- 5.3.2. Forging

- 5.3.3. Machining

- 5.3.4. Welding and Tubing

- 5.3.5. Other Services

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. India

- 5.1. Market Analysis, Insights and Forecast - by End-user Industry

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 Salasar Techno Engineering Ltd

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Kirby Building Systems

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 Zamil Industrial Investment Co

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Pennar Group

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 ISGEC Heavy Engineering Ltd

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Godrej Process Equipment

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 TEMA India

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 Larsen & Toubro Ltd

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 Diamond Group

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 Novatech Projects (India) Private Limited

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.11 SKV Engineering India Pvt LTD

- 6.2.11.1. Overview

- 6.2.11.2. Products

- 6.2.11.3. SWOT Analysis

- 6.2.11.4. Recent Developments

- 6.2.11.5. Financials (Based on Availability)

- 6.2.12 Karamtara Engineering Pvt Ltd**List Not Exhaustive 6 3 Other Companie

- 6.2.12.1. Overview

- 6.2.12.2. Products

- 6.2.12.3. SWOT Analysis

- 6.2.12.4. Recent Developments

- 6.2.12.5. Financials (Based on Availability)

- 6.2.1 Salasar Techno Engineering Ltd

List of Figures

- Figure 1: India Metal Fabrication Market Revenue Breakdown (billion, %) by Product 2025 & 2033

- Figure 2: India Metal Fabrication Market Share (%) by Company 2025

List of Tables

- Table 1: India Metal Fabrication Market Revenue billion Forecast, by End-user Industry 2020 & 2033

- Table 2: India Metal Fabrication Market Revenue billion Forecast, by Material Type 2020 & 2033

- Table 3: India Metal Fabrication Market Revenue billion Forecast, by Service Type 2020 & 2033

- Table 4: India Metal Fabrication Market Revenue billion Forecast, by Region 2020 & 2033

- Table 5: India Metal Fabrication Market Revenue billion Forecast, by End-user Industry 2020 & 2033

- Table 6: India Metal Fabrication Market Revenue billion Forecast, by Material Type 2020 & 2033

- Table 7: India Metal Fabrication Market Revenue billion Forecast, by Service Type 2020 & 2033

- Table 8: India Metal Fabrication Market Revenue billion Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the India Metal Fabrication Market?

The projected CAGR is approximately 5.27%.

2. Which companies are prominent players in the India Metal Fabrication Market?

Key companies in the market include Salasar Techno Engineering Ltd, Kirby Building Systems, Zamil Industrial Investment Co, Pennar Group, ISGEC Heavy Engineering Ltd, Godrej Process Equipment, TEMA India, Larsen & Toubro Ltd, Diamond Group, Novatech Projects (India) Private Limited, SKV Engineering India Pvt LTD, Karamtara Engineering Pvt Ltd**List Not Exhaustive 6 3 Other Companie.

3. What are the main segments of the India Metal Fabrication Market?

The market segments include End-user Industry, Material Type, Service Type.

4. Can you provide details about the market size?

The market size is estimated to be USD 2.91 billion as of 2022.

5. What are some drivers contributing to market growth?

Growing Demand for Fabricated Metal Products Driving the Market; Technological Advancements Driving the Market.

6. What are the notable trends driving market growth?

Manufacturing Sector is Shaping the Market.

7. Are there any restraints impacting market growth?

Growing Demand for Fabricated Metal Products Driving the Market; Technological Advancements Driving the Market.

8. Can you provide examples of recent developments in the market?

October 2023: JSP’s Angul unit, located in Odisha, was set to become India’s biggest single-location steel manufacturing plant. The capacity of the current Angul plant is estimated to be 5.6 mtpa per annum. However, the plan was to double it to 11 mtpa and 24 mtpa by 2023 and 2027, respectively. JSP’s steel plant, located in Raghurhat, was also expected to expand its capacity from 3.6 tpa per annum to 9 tpa by 2023. JSP finalized trial production at Angul in 2023 and commercial production by 2024. Jindal Steel and Power expects the Indian steel industry to grow in line with government infrastructure projects and domestic demand.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in billion.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "India Metal Fabrication Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the India Metal Fabrication Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the India Metal Fabrication Market?

To stay informed about further developments, trends, and reports in the India Metal Fabrication Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

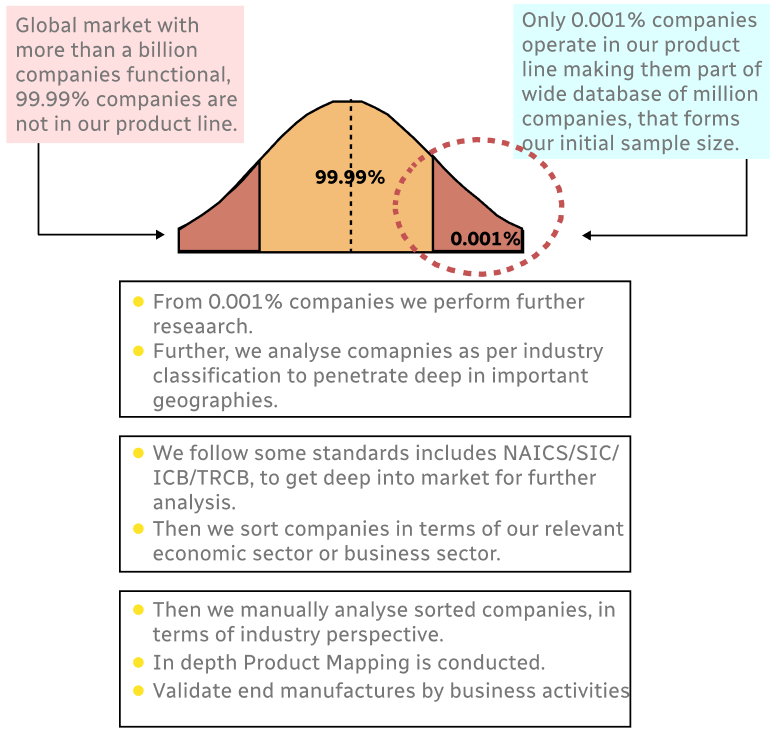

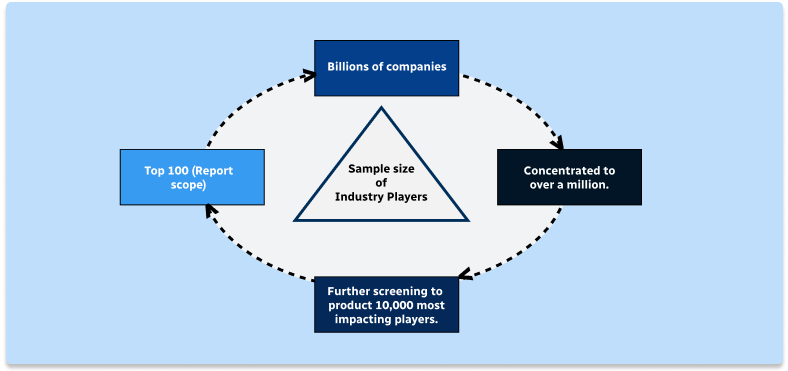

Step 1 - Identification of Relevant Samples Size from Population Database

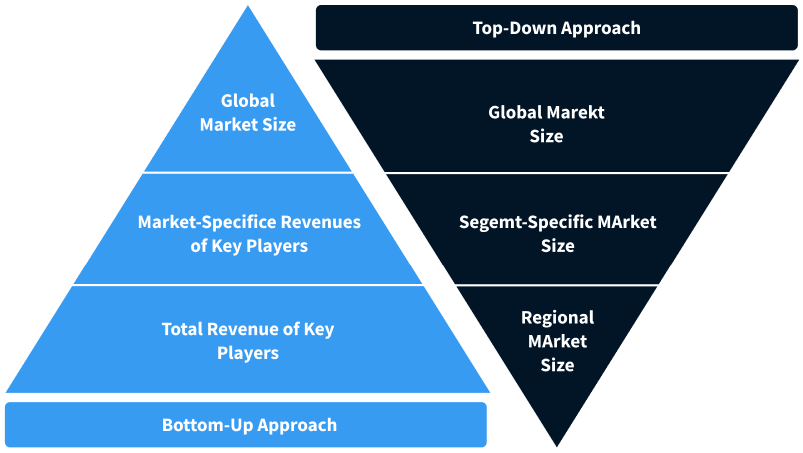

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

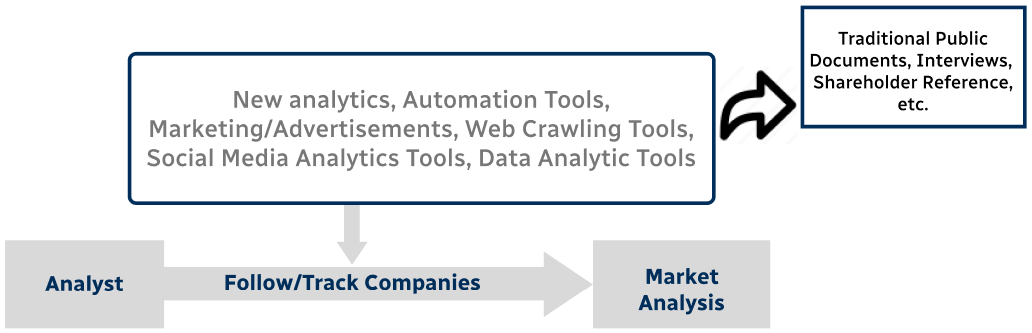

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence