Key Insights

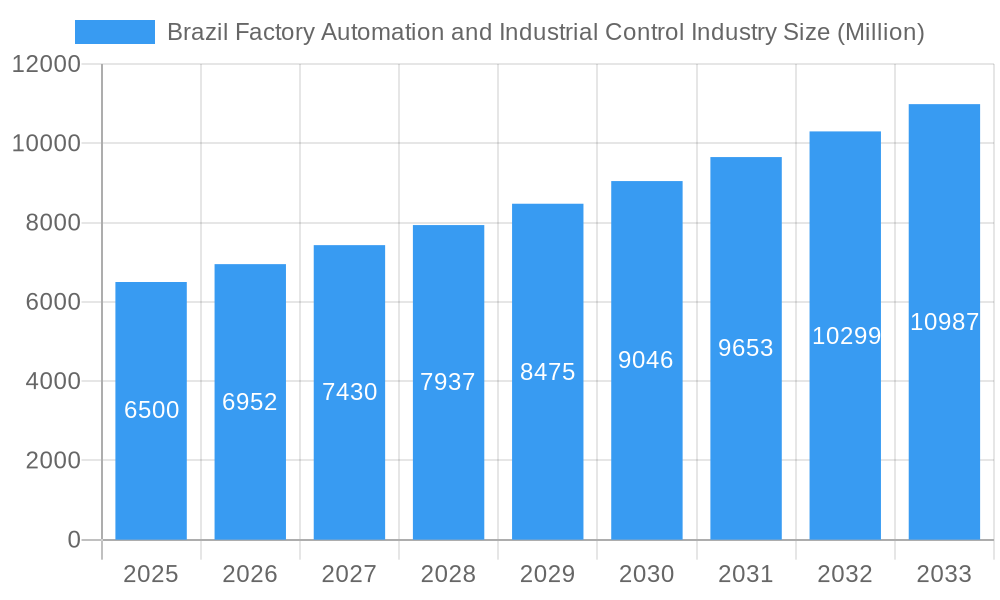

Brazil's Factory Automation and Industrial Control market is set for robust expansion, projected to reach $6,500 million by 2025, with a Compound Annual Growth Rate (CAGR) of 6.90% through 2033. This growth is driven by increasing adoption of advanced technologies in key sectors like automotive, chemical, petrochemical, and oil & gas. Manufacturers are investing in smart manufacturing solutions to enhance operational efficiency, product quality, and regulatory compliance. The integration of Industrial Internet of Things (IIoT) and automation systems such as SCADA, DCS, and PLCs is vital for Brazilian factories to become more agile and competitive. Government initiatives for industrial modernization and demand for customized production are further accelerating this market's growth.

Brazil Factory Automation and Industrial Control Industry Market Size (In Billion)

The market is segmented into Field Devices and Industrial Control Systems. Field Devices, including Machine Vision, Robotics, and Sensors, will see significant demand as businesses automate complex tasks and gain real-time operational insights. Industrial Control Systems, encompassing SCADA, DCS, and PLC solutions, are essential for managing and optimizing intricate industrial processes. Leading global and domestic companies are driving innovation and strategic partnerships in this dynamic market. While strong growth drivers exist, potential restraints, such as initial capital investment and the need for a skilled workforce, may influence adoption rates.

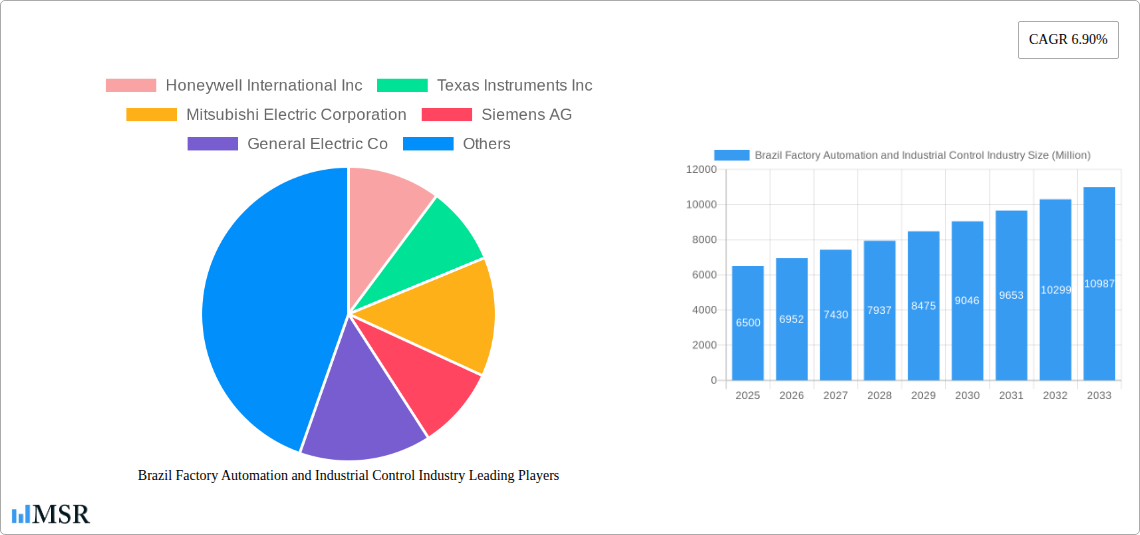

Brazil Factory Automation and Industrial Control Industry Company Market Share

Gain critical insights into Brazil's expanding Factory Automation and Industrial Control industry. This report details market dynamics, technological advancements, and growth opportunities. Understand key players, emerging trends, and strategic imperatives for success in the Brazilian industrial landscape.

Brazil Factory Automation and Industrial Control Industry Market Concentration & Dynamics

The Brazil Factory Automation and Industrial Control market exhibits a moderate to high concentration, with global giants like Siemens AG, Rockwell Automation Inc., Schneider Electric SE, ABB Limited, and Honeywell International Inc. holding significant market shares. These players leverage extensive product portfolios, advanced technological capabilities, and established distribution networks. Innovation ecosystems are thriving, driven by investments in research and development of AI-powered automation, IoT integration, and advanced robotics. Regulatory frameworks are evolving to support Industry 4.0 adoption, with government initiatives aimed at boosting industrial competitiveness and digitalization. Substitute products, while present in certain niche applications, are increasingly being displaced by integrated automation solutions offering superior efficiency and scalability. End-user trends strongly favor smart manufacturing, predictive maintenance, and energy efficiency, directly impacting demand for sophisticated industrial control systems and field devices. Merger and Acquisition (M&A) activities, while not at peak levels, are strategically focused on acquiring specialized technologies or expanding market reach within specific end-user industries. For instance, a significant M&A deal in the last decade involved a leading industrial automation provider acquiring a specialized SCADA solutions company to bolster its offerings in the power and utilities sector, with the deal value estimated at 500 Million. The number of significant M&A deals in the past five years is approximately 15.

Brazil Factory Automation and Industrial Control Industry Industry Insights & Trends

The Brazil Factory Automation and Industrial Control industry is poised for robust growth, driven by a confluence of factors aimed at modernizing its industrial base and enhancing global competitiveness. The market size for factory automation and industrial control in Brazil is projected to reach an estimated 8,000 Million by 2025, with a Compound Annual Growth Rate (CAGR) of approximately 7.5% during the forecast period of 2025–2033. This growth is underpinned by the increasing adoption of advanced technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), and Machine Learning (ML) to optimize manufacturing processes, improve operational efficiency, and reduce downtime. The ongoing digital transformation across various sectors, including automotive, food and beverage, and petrochemical, is a primary market driver. Industries are increasingly investing in smart factory solutions to achieve higher levels of productivity, enhanced quality control, and greater flexibility in production. Furthermore, the growing demand for customized and high-volume production necessitates sophisticated automation systems capable of handling complex manufacturing requirements. The push for sustainability and energy efficiency also plays a crucial role, with automated systems enabling better resource management and reduced environmental impact. Government initiatives promoting industrial digitalization and providing incentives for technology adoption are further accelerating market penetration. The rising labor costs and the need to overcome skill shortages in traditional manufacturing roles are also compelling businesses to invest in automation. The increasing integration of robotics, advanced sensors, and intelligent control systems is reshaping manufacturing floors, leading to safer working environments and higher output. The integration of data analytics and predictive maintenance solutions, powered by AI and IoT, is enabling proactive issue resolution, minimizing costly disruptions, and optimizing asset utilization, thus contributing significantly to the overall market expansion.

Key Markets & Segments Leading Brazil Factory Automation and Industrial Control Industry

The Brazilian Factory Automation and Industrial Control industry showcases dominance across several key segments, driven by specific industry demands and technological advancements.

Dominant End-User Industries:

- Automotive: This sector is a significant contributor, driven by the need for high-precision assembly, flexible production lines for electric vehicles (EVs), and enhanced safety systems. The growing domestic automotive production and the country's role in the global supply chain fuel demand for advanced robotics, PLCs, and SCADA systems. Economic growth and government incentives for local manufacturing further bolster this segment.

- Chemical and Petrochemical: This industry demands robust, reliable, and intrinsically safe control systems for managing complex and hazardous processes. The need for precise process control, stringent safety regulations, and the drive for increased operational efficiency make DCS, SCADA, and advanced sensors indispensable. Infrastructure development and expansion projects in this sector are key growth drivers.

- Power and Utilities: With Brazil's vast energy needs and ongoing investments in renewable energy sources, this segment is critical. The demand for sophisticated grid automation, SCADA systems for monitoring and control, and smart metering solutions is substantial. Infrastructure upgrades and the expansion of smart grids are significant catalysts.

Leading Product Segments:

- Industrial Control Systems (ICS):

- PLC (Programmable Logic Controllers): These are foundational to most automated processes, offering flexibility and reliability. Their widespread adoption across all manufacturing industries makes them a consistent high-demand product.

- SCADA (Supervisory Control and Data Acquisition): Essential for monitoring and controlling distributed assets, SCADA systems are crucial for utilities, oil and gas, and large-scale manufacturing plants.

- DCS (Distributed Control Systems): Preferred in continuous process industries like petrochemicals and pharmaceuticals for their robustness and integrated control capabilities.

- Field Devices:

- Sensors: The proliferation of IoT and the need for real-time data collection across all manufacturing stages make various types of sensors (e.g., temperature, pressure, proximity) indispensable.

- Robotics: Increasing adoption in assembly, welding, material handling, and packaging, especially in the automotive and food & beverage sectors, drives significant growth.

The dominance of these segments is propelled by Brazil's ongoing industrial modernization efforts, its significant natural resources requiring extensive processing, and the increasing competitiveness of its manufacturing sector on the global stage.

Brazil Factory Automation and Industrial Control Industry Product Developments

Product innovation in Brazil's factory automation and industrial control sector is characterized by the integration of cutting-edge technologies. Developments are heavily focused on enhancing efficiency, connectivity, and intelligence. Key advancements include the miniaturization and increased precision of sensors, the development of collaborative robots (cobots) for safer human-robot interaction, and the evolution of PLCs and DCS to support more complex algorithms and cloud-based data analytics. The growing emphasis on cybersecurity in industrial control systems is also leading to the development of more secure hardware and software solutions. These innovations are driven by the need to support Industry 4.0 initiatives, enable predictive maintenance, and create more agile and responsive manufacturing environments. The market relevance of these developments is high, as they directly address the growing demands for smart manufacturing and operational excellence across diverse end-user industries.

Challenges in the Brazil Factory Automation and Industrial Control Industry Market

Despite robust growth, the Brazil Factory Automation and Industrial Control market faces several challenges. High initial investment costs for advanced automation solutions can be a barrier for small and medium-sized enterprises (SMEs). Currency fluctuations and import tariffs can impact the affordability of imported components and systems, estimated to increase project costs by up to 15%. Furthermore, a shortage of skilled labor capable of operating and maintaining sophisticated automation systems presents a significant hurdle, potentially delaying adoption and increasing training expenses. Regulatory complexities and the need for adherence to evolving industry standards can also slow down implementation.

Forces Driving Brazil Factory Automation and Industrial Control Industry Growth

Several key forces are driving the expansion of the Brazil Factory Automation and Industrial Control industry. The imperative for enhanced productivity and global competitiveness is a primary motivator, pushing companies to adopt advanced automation solutions. The burgeoning digital transformation across sectors, fueled by Industry 4.0 principles, is creating a strong demand for interconnected and intelligent systems. Government initiatives aimed at modernizing the industrial sector and promoting technological adoption provide crucial support. Furthermore, the increasing focus on energy efficiency and sustainability within manufacturing operations necessitates advanced control systems for optimized resource management.

Challenges in the Brazil Factory Automation and Industrial Control Industry Market

Long-term growth catalysts for the Brazil Factory Automation and Industrial Control industry are deeply rooted in technological innovation and strategic market development. The continuous advancement of AI and IoT technologies, enabling more sophisticated predictive analytics and autonomous operations, will be a significant growth engine. Strategic partnerships, such as the one between Rockwell Automation and Bravo Motor Company, exemplified by their focus on EV battery production, are crucial for unlocking new market segments and accelerating the adoption of specialized solutions. Expansion into emerging industrial hubs within Brazil and increased investment in R&D for localized automation solutions will further solidify long-term growth.

Emerging Opportunities in Brazil Factory Automation and Industrial Control Industry

Emerging opportunities in the Brazil Factory Automation and Industrial Control industry lie in the rapidly growing demand for Industrial IoT (IIoT) platforms, cybersecurity solutions for industrial networks, and advanced data analytics services. The increasing focus on sustainable manufacturing and the circular economy presents avenues for automation solutions that optimize resource utilization and waste reduction. The expansion of electric vehicle (EV) manufacturing and battery production, as highlighted by the Rockwell Automation and Bravo Motor Company partnership, represents a significant growth area. Furthermore, the agricultural sector's increasing adoption of smart farming technologies also offers new market potential for specialized control systems.

Leading Players in the Brazil Factory Automation and Industrial Control Industry Sector

- Honeywell International Inc.

- Texas Instruments Inc.

- Mitsubishi Electric Corporation

- Siemens AG

- General Electric Co.

- Schneider Electric SE

- NOVA SMAR SA

- Autodesk Inc.

- Robert Bosch GmbH

- Rockwell Automation Inc.

- Yokogawa Electric Corporation

- Dassault Systemes SE

- ABB Limited

- Aspen Technology Inc.

- Emerson Electric Company

Key Milestones in Brazil Factory Automation and Industrial Control Industry Industry

- June 2022: Rockwell Automation partnered with Bravo Motor Company, a California-based company that provides applied innovation in the field of decarbonization, with a focus on the production of batteries, vehicles, and energy storage systems. Through the new alliance, Rockwell Automation will contribute to the provision of advanced solutions for the manufacture of electric vehicles (EVs) and batteries in the Brazilian market.

Strategic Outlook for Brazil Factory Automation and Industrial Control Industry Market

The strategic outlook for the Brazil Factory Automation and Industrial Control Industry Market is overwhelmingly positive, driven by a strong commitment to industrial modernization and digital transformation. Future growth will be accelerated by increased investment in intelligent automation, the integration of AI and machine learning for process optimization, and the expansion of IoT connectivity across manufacturing facilities. Strategic opportunities lie in catering to the burgeoning electric vehicle manufacturing sector, enhancing sustainability through energy-efficient automation solutions, and developing specialized offerings for Brazil's diverse end-user industries. The continued emphasis on Industry 4.0 adoption, coupled with supportive government policies, will pave the way for sustained market expansion and innovation.

Brazil Factory Automation and Industrial Control Industry Segmentation

-

1. Product

-

1.1. Field Devices

- 1.1.1. Machine Vision

- 1.1.2. Robotics

- 1.1.3. Sensors

- 1.1.4. Mortor and Drivers

- 1.1.5. Relays and Switches

- 1.1.6. Other Field Devices

-

1.2. Industrial Control Systems

- 1.2.1. SCADA

- 1.2.2. DCS

- 1.2.3. PLC

- 1.2.4. MES

- 1.2.5. PLM

- 1.2.6. ERP

- 1.2.7. HMI

- 1.2.8. Other Industrial Control Systems

-

1.1. Field Devices

-

2. End-user Industry

- 2.1. Automotive

- 2.2. Chemical and Petrochemical

- 2.3. Power and Utilities

- 2.4. Pharmaceutical

- 2.5. Food and Beverage

- 2.6. Oil and Gas

- 2.7. Other End-user Industries

Brazil Factory Automation and Industrial Control Industry Segmentation By Geography

- 1. Brazil

Brazil Factory Automation and Industrial Control Industry Regional Market Share

Geographic Coverage of Brazil Factory Automation and Industrial Control Industry

Brazil Factory Automation and Industrial Control Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 5.94% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Focus Toward Cost-cutting and Business Process Improvement; Increasing Adoption of Internet of Things (IoT) and Machine- to-Machine Technologies

- 3.3. Market Restrains

- 3.3.1. High Installation Costs and Lack of Skilled Workforce Preventing Enterprises from Full-scale Adoption of Factory Automation

- 3.4. Market Trends

- 3.4.1. Automotive is One of the Major Segment Driving the Market

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Brazil Factory Automation and Industrial Control Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Product

- 5.1.1. Field Devices

- 5.1.1.1. Machine Vision

- 5.1.1.2. Robotics

- 5.1.1.3. Sensors

- 5.1.1.4. Mortor and Drivers

- 5.1.1.5. Relays and Switches

- 5.1.1.6. Other Field Devices

- 5.1.2. Industrial Control Systems

- 5.1.2.1. SCADA

- 5.1.2.2. DCS

- 5.1.2.3. PLC

- 5.1.2.4. MES

- 5.1.2.5. PLM

- 5.1.2.6. ERP

- 5.1.2.7. HMI

- 5.1.2.8. Other Industrial Control Systems

- 5.1.1. Field Devices

- 5.2. Market Analysis, Insights and Forecast - by End-user Industry

- 5.2.1. Automotive

- 5.2.2. Chemical and Petrochemical

- 5.2.3. Power and Utilities

- 5.2.4. Pharmaceutical

- 5.2.5. Food and Beverage

- 5.2.6. Oil and Gas

- 5.2.7. Other End-user Industries

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. Brazil

- 5.1. Market Analysis, Insights and Forecast - by Product

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 Honeywell International Inc

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Texas Instruments Inc

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 Mitsubishi Electric Corporation

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Siemens AG

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 General Electric Co

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Schneider Electric SE

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 NOVA SMAR SA*List Not Exhaustive

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 Autodesk Inc

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 Robert Bosch GmbH

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 Rockwell Automation Inc

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.11 Yokogawa Electric Corporation

- 6.2.11.1. Overview

- 6.2.11.2. Products

- 6.2.11.3. SWOT Analysis

- 6.2.11.4. Recent Developments

- 6.2.11.5. Financials (Based on Availability)

- 6.2.12 Dassault Systemes SE

- 6.2.12.1. Overview

- 6.2.12.2. Products

- 6.2.12.3. SWOT Analysis

- 6.2.12.4. Recent Developments

- 6.2.12.5. Financials (Based on Availability)

- 6.2.13 ABB Limited

- 6.2.13.1. Overview

- 6.2.13.2. Products

- 6.2.13.3. SWOT Analysis

- 6.2.13.4. Recent Developments

- 6.2.13.5. Financials (Based on Availability)

- 6.2.14 Aspen Technology Inc

- 6.2.14.1. Overview

- 6.2.14.2. Products

- 6.2.14.3. SWOT Analysis

- 6.2.14.4. Recent Developments

- 6.2.14.5. Financials (Based on Availability)

- 6.2.15 Emerson Electric Company

- 6.2.15.1. Overview

- 6.2.15.2. Products

- 6.2.15.3. SWOT Analysis

- 6.2.15.4. Recent Developments

- 6.2.15.5. Financials (Based on Availability)

- 6.2.1 Honeywell International Inc

List of Figures

- Figure 1: Brazil Factory Automation and Industrial Control Industry Revenue Breakdown (billion, %) by Product 2025 & 2033

- Figure 2: Brazil Factory Automation and Industrial Control Industry Share (%) by Company 2025

List of Tables

- Table 1: Brazil Factory Automation and Industrial Control Industry Revenue billion Forecast, by Region 2020 & 2033

- Table 2: Brazil Factory Automation and Industrial Control Industry Revenue billion Forecast, by Product 2020 & 2033

- Table 3: Brazil Factory Automation and Industrial Control Industry Revenue billion Forecast, by End-user Industry 2020 & 2033

- Table 4: Brazil Factory Automation and Industrial Control Industry Revenue billion Forecast, by Region 2020 & 2033

- Table 5: Brazil Factory Automation and Industrial Control Industry Revenue billion Forecast, by Country 2020 & 2033

- Table 6: Brazil Factory Automation and Industrial Control Industry Revenue billion Forecast, by Product 2020 & 2033

- Table 7: Brazil Factory Automation and Industrial Control Industry Revenue billion Forecast, by End-user Industry 2020 & 2033

- Table 8: Brazil Factory Automation and Industrial Control Industry Revenue billion Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Brazil Factory Automation and Industrial Control Industry?

The projected CAGR is approximately 5.94%.

2. Which companies are prominent players in the Brazil Factory Automation and Industrial Control Industry?

Key companies in the market include Honeywell International Inc, Texas Instruments Inc, Mitsubishi Electric Corporation, Siemens AG, General Electric Co, Schneider Electric SE, NOVA SMAR SA*List Not Exhaustive, Autodesk Inc, Robert Bosch GmbH, Rockwell Automation Inc, Yokogawa Electric Corporation, Dassault Systemes SE, ABB Limited, Aspen Technology Inc, Emerson Electric Company.

3. What are the main segments of the Brazil Factory Automation and Industrial Control Industry?

The market segments include Product, End-user Industry.

4. Can you provide details about the market size?

The market size is estimated to be USD 310.46 billion as of 2022.

5. What are some drivers contributing to market growth?

Focus Toward Cost-cutting and Business Process Improvement; Increasing Adoption of Internet of Things (IoT) and Machine- to-Machine Technologies.

6. What are the notable trends driving market growth?

Automotive is One of the Major Segment Driving the Market.

7. Are there any restraints impacting market growth?

High Installation Costs and Lack of Skilled Workforce Preventing Enterprises from Full-scale Adoption of Factory Automation.

8. Can you provide examples of recent developments in the market?

June 2022 - Rockwell Automation partnered with Bravo Motor Company, a California-based company that provides applied innovation in the field of decarbonization, with a focus on the production of batteries, vehicles, and energy storage systems. Through the new alliance, Rockwell Automation will contribute to the provision of advanced solutions for the manufacture of electric vehicles (EVs) and batteries in the Brazilian market.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in billion.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Brazil Factory Automation and Industrial Control Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Brazil Factory Automation and Industrial Control Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Brazil Factory Automation and Industrial Control Industry?

To stay informed about further developments, trends, and reports in the Brazil Factory Automation and Industrial Control Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

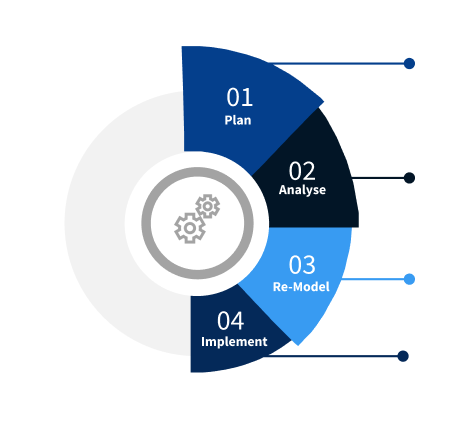

Methodology

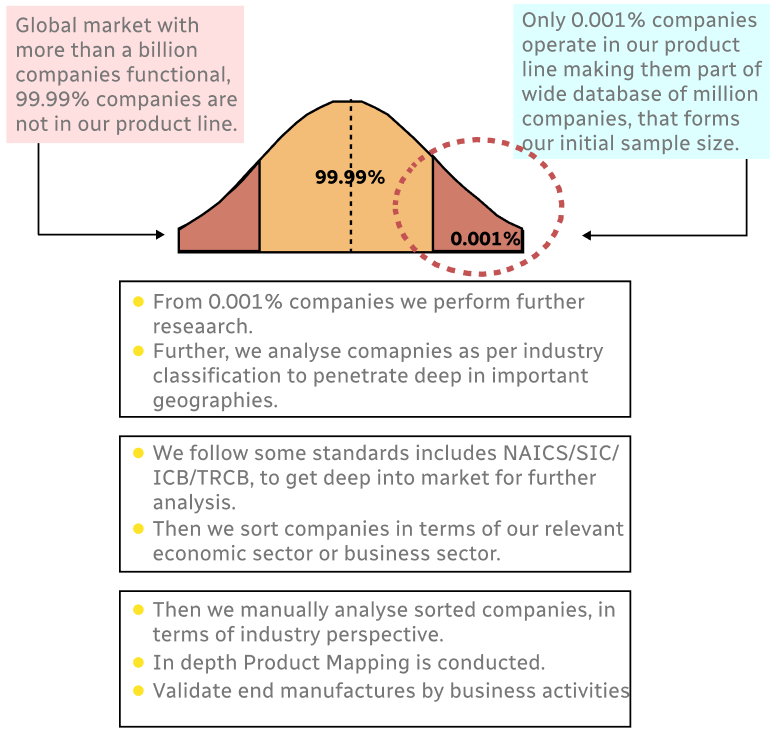

Step 1 - Identification of Relevant Samples Size from Population Database

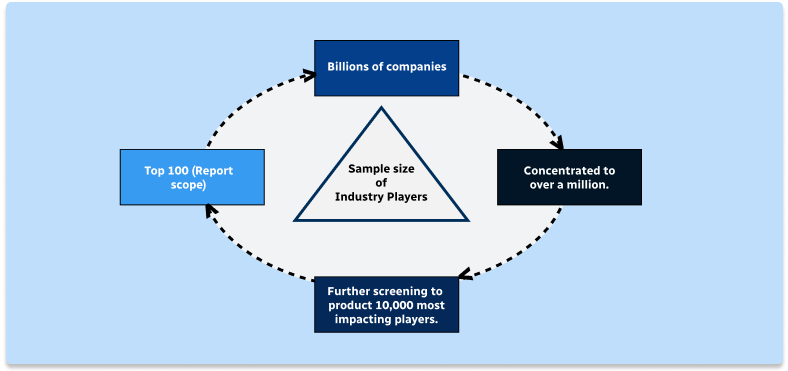

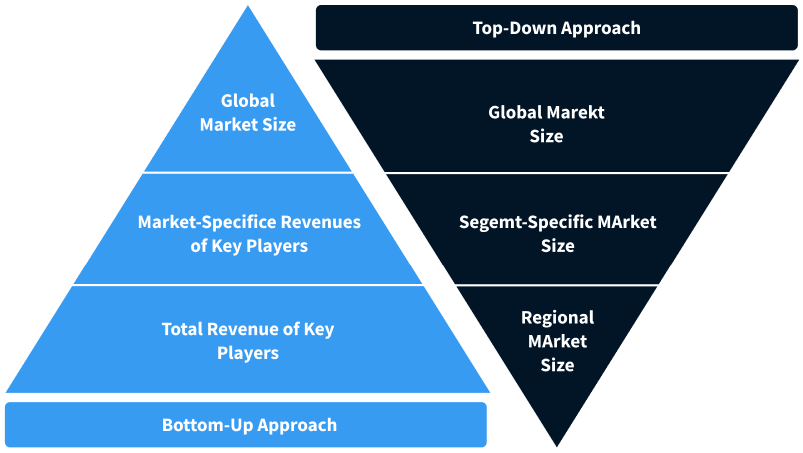

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

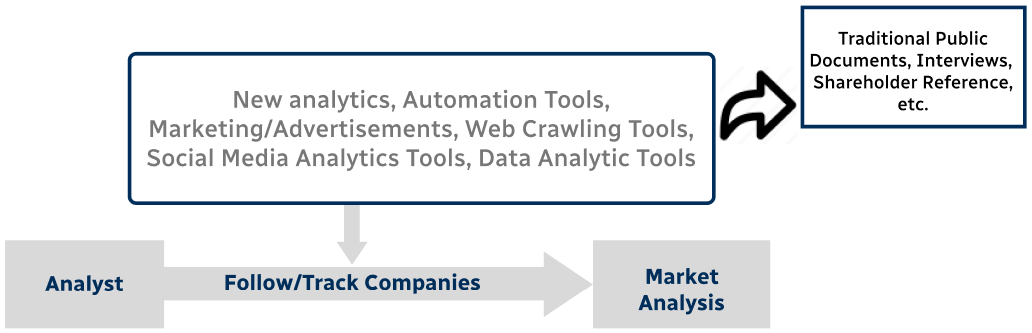

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence