Key Insights

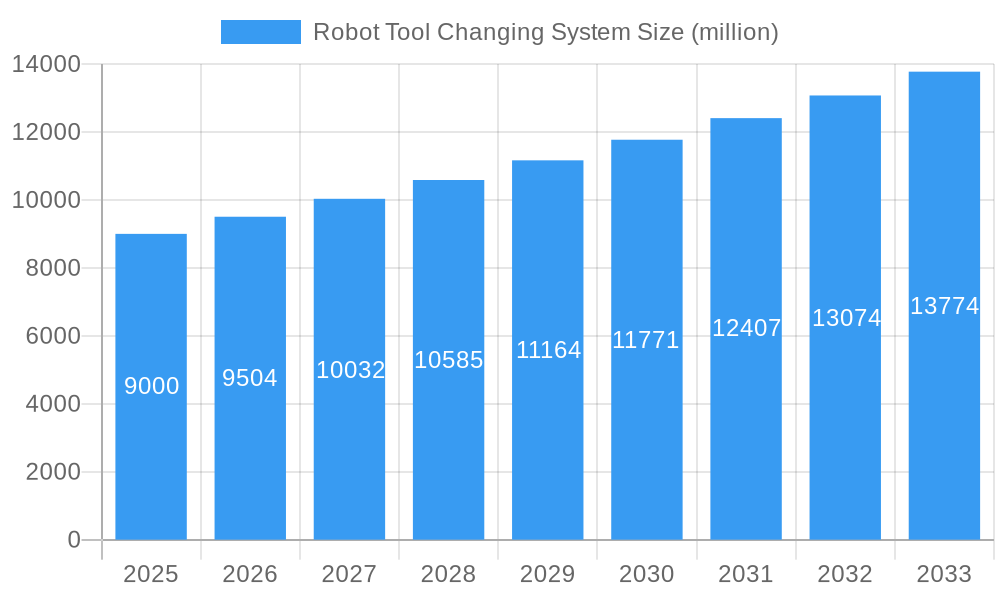

The global Robot Tool Changing System market is poised for robust expansion, with a projected market size of USD 9 billion in 2025, driven by an estimated Compound Annual Growth Rate (CAGR) of 5.6% through 2033. This growth is primarily fueled by the increasing adoption of industrial automation across diverse sectors, including automotive, electronics, and logistics. The demand for enhanced manufacturing efficiency, reduced downtime, and greater operational flexibility directly translates into a growing need for sophisticated robot tool changers. The market is segmented by application into Light Payload (Less Than 300 Kg), Medium Payload (300-1000 Kg), and Heavy Payload (Greater Than 1000 Kg), with the medium and heavy payload segments expected to witness significant traction due to their application in complex and high-volume production environments. Automatic Robot Tool Changers, offering seamless and rapid tool exchanges, are leading the market over their manual counterparts, reflecting the industry's pursuit of greater autonomy and productivity. Key players like ATI, Staubli, and Schunk are at the forefront of innovation, introducing advanced solutions that cater to evolving industrial needs.

Robot Tool Changing System Market Size (In Billion)

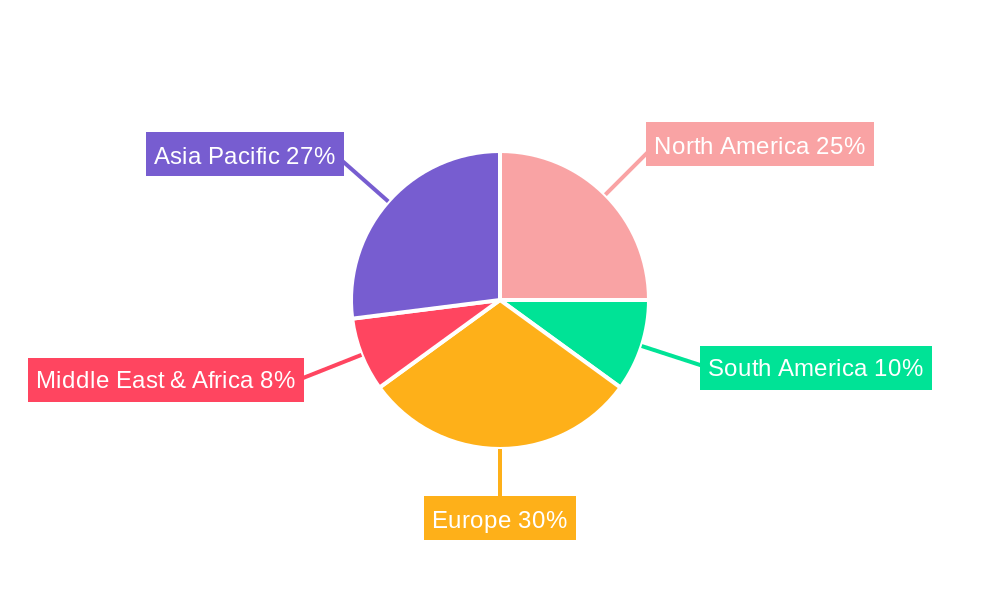

Geographically, Asia Pacific is expected to emerge as a dominant region, propelled by the rapid industrialization in China, India, and ASEAN nations, coupled with substantial investments in smart manufacturing. North America and Europe, with their established automotive and manufacturing industries, will continue to be significant markets, driven by the need to maintain competitiveness through automation. The Middle East & Africa region presents emerging opportunities, while South America is also showing promising growth. While the market is experiencing a strong upward trajectory, potential restraints such as the high initial investment costs for advanced tool changing systems and the need for skilled personnel to operate and maintain them, may pose challenges. However, continuous technological advancements, development of more cost-effective solutions, and increasing government support for automation initiatives are expected to mitigate these concerns, ensuring sustained market growth throughout the forecast period.

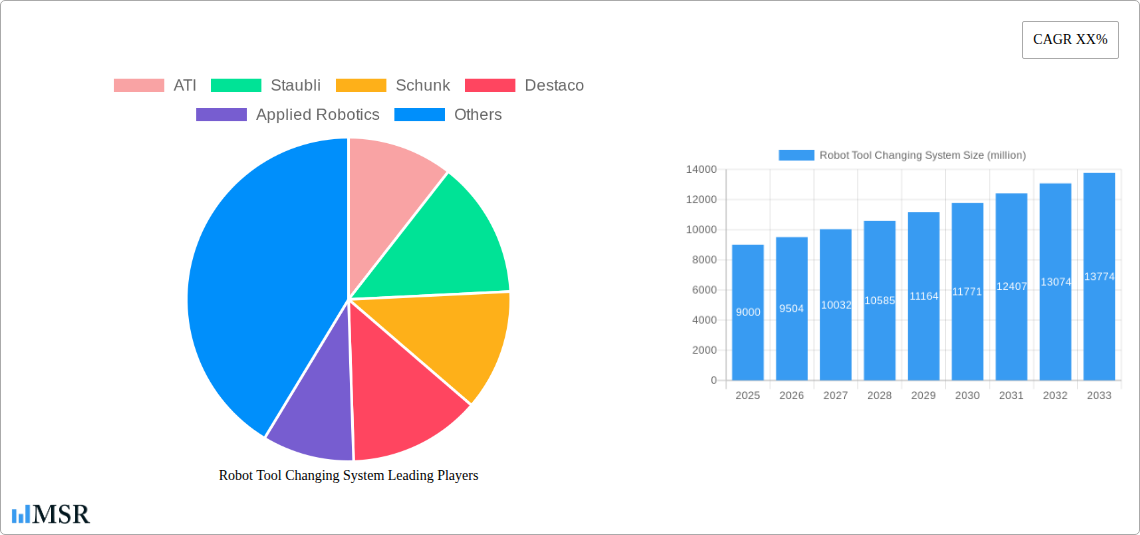

Robot Tool Changing System Company Market Share

Robot Tool Changing System Market: Comprehensive Analysis & Future Outlook (2019-2033)

This comprehensive report provides an in-depth analysis of the global Robot Tool Changing System market. Covering the historical period from 2019 to 2024, the base year of 2025, and a detailed forecast extending to 2033, this study offers critical insights for industry stakeholders. The report dissects market dynamics, technological advancements, key application segments, leading players, and emerging opportunities, equipping businesses with actionable intelligence to navigate this rapidly evolving sector. With an estimated market size of over 10 billion USD in 2025 and a projected Compound Annual Growth Rate (CAGR) of approximately 6.5 billion USD from 2025 to 2033, the Robot Tool Changing System market presents significant growth potential.

Robot Tool Changing System Market Concentration & Dynamics

The global Robot Tool Changing System market exhibits a moderately concentrated landscape, with several key players dominating the innovation and supply chain. Major companies such as ATI, Staubli, Schunk, Destaco, Applied Robotics, RSP, AGI, Nitta, Pascal, Carl Kurt Walther, Robotic & Automation Tooling, OBARA Corporation are actively shaping the market through continuous research and development. The innovation ecosystem is characterized by strategic collaborations and a focus on enhancing system efficiency, payload capacity, and integration flexibility. Regulatory frameworks, while not overly restrictive, are increasingly focused on safety standards and interoperability, pushing for more standardized solutions. Substitute products, such as manual tool changing methods, are gradually being phased out in favor of automated solutions due to their inherent inefficiencies and safety concerns. End-user trends are shifting towards higher automation levels, demanding more sophisticated and adaptable tool changing systems across various industries. Merger and acquisition (M&A) activities, estimated at over 15 significant deals between 2019 and 2033, are a key dynamic, with larger entities acquiring specialized technology providers to expand their product portfolios and market reach. Market share analysis reveals that the top five players collectively hold over 60% of the market.

Robot Tool Changing System Industry Insights & Trends

The Robot Tool Changing System industry is experiencing robust growth, driven by the escalating demand for increased manufacturing efficiency, enhanced flexibility, and reduced downtime. The market size for Robot Tool Changing Systems is projected to exceed 15 billion USD by the end of 2033, with a significant CAGR of approximately 6.5 billion USD from 2025 to 2033. Technological disruptions, including the integration of Industry 4.0 principles, AI-powered diagnostics, and advanced sensor technologies, are fundamentally reshaping the capabilities of these systems. Evolving consumer behaviors, particularly the increasing preference for mass customization and shorter product lifecycles, necessitate agile manufacturing processes that are directly supported by efficient tool changing solutions. The proliferation of collaborative robots (cobots) also presents a substantial growth avenue, requiring specialized, lighter, and safer tool changers. Furthermore, the growing adoption of robotics in industries beyond traditional manufacturing, such as logistics, healthcare, and agriculture, is creating new demand for diverse tool changing functionalities. The development of smart, connected tool changers that can communicate with robotic arms and enterprise resource planning (ERP) systems is a key trend, enabling predictive maintenance and optimized production scheduling. The market is witnessing a continuous drive towards smaller, lighter, and more powerful tool changers capable of handling increased payloads and a wider variety of end-effectors.

Key Markets & Segments Leading Robot Tool Changing System

The global Robot Tool Changing System market is characterized by strong performance across various application segments and geographical regions.

Dominant Regions and Countries:

- Asia Pacific: This region is a significant growth engine, propelled by its robust manufacturing base, substantial investments in automation, and the presence of key automotive and electronics industries. Countries like China, Japan, and South Korea are at the forefront of adoption, driven by government initiatives promoting industrial modernization. Economic growth and a strong focus on supply chain resilience are key drivers here.

- North America: The United States, in particular, is a mature market with a high adoption rate of advanced robotics, including sophisticated tool changing systems. The re-shoring trend and the emphasis on smart manufacturing are contributing to sustained growth. Infrastructure development and a skilled workforce are pivotal factors.

- Europe: Germany, France, and the UK represent key markets within Europe, with a strong presence of automotive, aerospace, and industrial machinery manufacturers. The region's commitment to Industry 4.0 and sustainability further fuels demand for efficient robotic solutions.

Dominant Segments:

- Application: Medium Payload (300-1000 Kg): This segment is experiencing the most significant demand due to its wide applicability across diverse manufacturing sectors, particularly in automotive assembly, welding, and material handling. The balance of versatility and robust performance makes it a preferred choice for many industrial automation projects.

- Drivers: Increasing automation in mid-sized manufacturing operations, rising demand for adaptable production lines, and the growth of industries like general manufacturing and packaging.

- Types: Automatic Robot Tool Changers: Automatic systems represent the largest and fastest-growing segment. Their ability to facilitate rapid and seamless tool changes without human intervention is crucial for maximizing robot utilization and overall production throughput.

- Drivers: The imperative for increased production efficiency, reduction of labor costs associated with manual tool changes, and the need for high-speed, flexible manufacturing environments.

- Application: Heavy Payload (Greater Than 1000 Kg): While smaller in volume, this segment is critical for heavy industries such as aerospace, construction, and heavy machinery manufacturing. Advancements in robust and reliable heavy-duty tool changers are expanding their adoption.

- Drivers: The need for automation in complex and hazardous heavy industries, increasing demand for larger robotic systems in specialized applications, and advancements in material science for more durable components.

- Application: Light Payload (Less Than 300 Kg): This segment is growing due to the increasing popularity of collaborative robots and smaller industrial robots in sectors like electronics assembly, packaging, and logistics.

- Drivers: The rise of cobots, demand for automation in smaller enterprises, and applications requiring precision and agility.

Robot Tool Changing System Product Developments

Recent product developments in Robot Tool Changing Systems are focused on enhancing speed, accuracy, payload capacity, and smart integration. Innovations include ultra-lightweight designs for cobots, advanced locking mechanisms for enhanced safety and rigidity, and integrated sensor suites for real-time performance monitoring and diagnostics. The market is witnessing the introduction of modular systems that allow for quick customization and adaptation to evolving application needs. Furthermore, advancements in wireless connectivity and data exchange are enabling seamless integration with higher-level manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms, paving the way for truly intelligent automation.

Challenges in the Robot Tool Changing System Market

Despite robust growth, the Robot Tool Changing System market faces several challenges. High initial investment costs can be a barrier for small and medium-sized enterprises (SMEs). The need for specialized training to operate and maintain these complex systems also poses a hurdle. Supply chain disruptions, particularly for specialized components, can impact production timelines and availability. Additionally, ensuring interoperability and standardization across different robot brands and tool changer manufacturers remains an ongoing challenge.

Forces Driving Robot Tool Changing System Growth

Several key forces are propelling the growth of the Robot Tool Changing System market. The relentless pursuit of enhanced manufacturing efficiency and productivity is a primary driver. The growing adoption of Industry 4.0 and smart manufacturing principles necessitates automated solutions like robot tool changers for seamless integration and data-driven optimization. Economic factors, including rising labor costs and the need to remain competitive globally, encourage investment in automation. Furthermore, government initiatives and incentives promoting advanced manufacturing and robotics adoption in various countries are significantly contributing to market expansion.

Challenges in the Robot Tool Changing System Market

Long-term growth catalysts for the Robot Tool Changing System market are deeply rooted in continuous technological innovation and strategic market expansion. The development of AI-powered predictive maintenance for tool changers, offering proactive identification of potential failures and minimizing unplanned downtime, is a significant catalyst. Furthermore, the expansion of robotics into emerging industries such as healthcare, logistics, and even agriculture will create new demand for specialized and adaptable tool changing solutions. Strategic partnerships between tool changer manufacturers and robot manufacturers, aimed at developing co-engineered solutions, will also accelerate adoption and market penetration.

Emerging Opportunities in Robot Tool Changing System

Emerging opportunities in the Robot Tool Changing System market lie in the development of highly specialized solutions for niche applications. The burgeoning field of collaborative robotics presents a significant opportunity for compact, lightweight, and inherently safe tool changers. The increasing demand for mass customization and flexible manufacturing requires tool changers that can handle an even wider variety of end-effectors with extreme speed and precision. Furthermore, the integration of advanced sensing and artificial intelligence for real-time performance monitoring and self-optimization will open up new avenues for value-added services and smart factory integration, especially in sectors like food and beverage and pharmaceuticals.

Leading Players in the Robot Tool Changing System Sector

- ATI

- Staubli

- Schunk

- Destaco

- Applied Robotics

- RSP

- AGI

- Nitta

- Pascal

- Carl Kurt Walther

- Robotic & Automation Tooling

- OBARA Corporation

Key Milestones in Robot Tool Changing System Industry

- 2019: Introduction of enhanced safety features and faster locking mechanisms in heavy-duty tool changers.

- 2020: Increased focus on modular tool changer designs for greater application flexibility.

- 2021: Significant advancements in lightweight tool changers for collaborative robot applications.

- 2022: Development of smart tool changers with integrated diagnostics and communication capabilities.

- 2023: Strategic acquisitions aimed at consolidating market share and expanding technological portfolios.

- 2024: Rise in demand for tool changers supporting advanced welding and assembly processes.

Strategic Outlook for Robot Tool Changing System Market

The strategic outlook for the Robot Tool Changing System market is exceptionally promising, characterized by continued innovation and expanding application frontiers. Future growth will be accelerated by the increasing integration of AI and IoT technologies, enabling smarter, more autonomous tool changing operations. Strategic opportunities lie in developing solutions tailored for emerging sectors and in fostering deeper collaborations across the automation ecosystem. The focus on sustainability and energy efficiency in product design will also become a key differentiator, positioning the market for sustained expansion and technological leadership.

Robot Tool Changing System Segmentation

-

1. Application

- 1.1. Light Payload (Less Than 300 Kg)

- 1.2. Medium Payload (300-1000 Kg)

- 1.3. Heavy Payload (Greater Than 1000 Kg)

-

2. Types

- 2.1. Manual Robot Tool Changers

- 2.2. Automatic Robot Tool Changers

Robot Tool Changing System Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Mexico

-

2. South America

- 2.1. Brazil

- 2.2. Argentina

- 2.3. Rest of South America

-

3. Europe

- 3.1. United Kingdom

- 3.2. Germany

- 3.3. France

- 3.4. Italy

- 3.5. Spain

- 3.6. Russia

- 3.7. Benelux

- 3.8. Nordics

- 3.9. Rest of Europe

-

4. Middle East & Africa

- 4.1. Turkey

- 4.2. Israel

- 4.3. GCC

- 4.4. North Africa

- 4.5. South Africa

- 4.6. Rest of Middle East & Africa

-

5. Asia Pacific

- 5.1. China

- 5.2. India

- 5.3. Japan

- 5.4. South Korea

- 5.5. ASEAN

- 5.6. Oceania

- 5.7. Rest of Asia Pacific

Robot Tool Changing System Regional Market Share

Geographic Coverage of Robot Tool Changing System

Robot Tool Changing System REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 5.6% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Robot Tool Changing System Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Application

- 5.1.1. Light Payload (Less Than 300 Kg)

- 5.1.2. Medium Payload (300-1000 Kg)

- 5.1.3. Heavy Payload (Greater Than 1000 Kg)

- 5.2. Market Analysis, Insights and Forecast - by Types

- 5.2.1. Manual Robot Tool Changers

- 5.2.2. Automatic Robot Tool Changers

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. South America

- 5.3.3. Europe

- 5.3.4. Middle East & Africa

- 5.3.5. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Application

- 6. North America Robot Tool Changing System Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Application

- 6.1.1. Light Payload (Less Than 300 Kg)

- 6.1.2. Medium Payload (300-1000 Kg)

- 6.1.3. Heavy Payload (Greater Than 1000 Kg)

- 6.2. Market Analysis, Insights and Forecast - by Types

- 6.2.1. Manual Robot Tool Changers

- 6.2.2. Automatic Robot Tool Changers

- 6.1. Market Analysis, Insights and Forecast - by Application

- 7. South America Robot Tool Changing System Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Application

- 7.1.1. Light Payload (Less Than 300 Kg)

- 7.1.2. Medium Payload (300-1000 Kg)

- 7.1.3. Heavy Payload (Greater Than 1000 Kg)

- 7.2. Market Analysis, Insights and Forecast - by Types

- 7.2.1. Manual Robot Tool Changers

- 7.2.2. Automatic Robot Tool Changers

- 7.1. Market Analysis, Insights and Forecast - by Application

- 8. Europe Robot Tool Changing System Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Application

- 8.1.1. Light Payload (Less Than 300 Kg)

- 8.1.2. Medium Payload (300-1000 Kg)

- 8.1.3. Heavy Payload (Greater Than 1000 Kg)

- 8.2. Market Analysis, Insights and Forecast - by Types

- 8.2.1. Manual Robot Tool Changers

- 8.2.2. Automatic Robot Tool Changers

- 8.1. Market Analysis, Insights and Forecast - by Application

- 9. Middle East & Africa Robot Tool Changing System Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Application

- 9.1.1. Light Payload (Less Than 300 Kg)

- 9.1.2. Medium Payload (300-1000 Kg)

- 9.1.3. Heavy Payload (Greater Than 1000 Kg)

- 9.2. Market Analysis, Insights and Forecast - by Types

- 9.2.1. Manual Robot Tool Changers

- 9.2.2. Automatic Robot Tool Changers

- 9.1. Market Analysis, Insights and Forecast - by Application

- 10. Asia Pacific Robot Tool Changing System Analysis, Insights and Forecast, 2020-2032

- 10.1. Market Analysis, Insights and Forecast - by Application

- 10.1.1. Light Payload (Less Than 300 Kg)

- 10.1.2. Medium Payload (300-1000 Kg)

- 10.1.3. Heavy Payload (Greater Than 1000 Kg)

- 10.2. Market Analysis, Insights and Forecast - by Types

- 10.2.1. Manual Robot Tool Changers

- 10.2.2. Automatic Robot Tool Changers

- 10.1. Market Analysis, Insights and Forecast - by Application

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2025

- 11.2. Company Profiles

- 11.2.1 ATI

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Staubli

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 Schunk

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 Destaco

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 Applied Robotics

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 RSP

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 AGI

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 Nitta

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 Pascal

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Carl Kurt Walther

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 Robotic & Automation Tooling

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.12 OBARA Corporation

- 11.2.12.1. Overview

- 11.2.12.2. Products

- 11.2.12.3. SWOT Analysis

- 11.2.12.4. Recent Developments

- 11.2.12.5. Financials (Based on Availability)

- 11.2.1 ATI

List of Figures

- Figure 1: Global Robot Tool Changing System Revenue Breakdown (undefined, %) by Region 2025 & 2033

- Figure 2: North America Robot Tool Changing System Revenue (undefined), by Application 2025 & 2033

- Figure 3: North America Robot Tool Changing System Revenue Share (%), by Application 2025 & 2033

- Figure 4: North America Robot Tool Changing System Revenue (undefined), by Types 2025 & 2033

- Figure 5: North America Robot Tool Changing System Revenue Share (%), by Types 2025 & 2033

- Figure 6: North America Robot Tool Changing System Revenue (undefined), by Country 2025 & 2033

- Figure 7: North America Robot Tool Changing System Revenue Share (%), by Country 2025 & 2033

- Figure 8: South America Robot Tool Changing System Revenue (undefined), by Application 2025 & 2033

- Figure 9: South America Robot Tool Changing System Revenue Share (%), by Application 2025 & 2033

- Figure 10: South America Robot Tool Changing System Revenue (undefined), by Types 2025 & 2033

- Figure 11: South America Robot Tool Changing System Revenue Share (%), by Types 2025 & 2033

- Figure 12: South America Robot Tool Changing System Revenue (undefined), by Country 2025 & 2033

- Figure 13: South America Robot Tool Changing System Revenue Share (%), by Country 2025 & 2033

- Figure 14: Europe Robot Tool Changing System Revenue (undefined), by Application 2025 & 2033

- Figure 15: Europe Robot Tool Changing System Revenue Share (%), by Application 2025 & 2033

- Figure 16: Europe Robot Tool Changing System Revenue (undefined), by Types 2025 & 2033

- Figure 17: Europe Robot Tool Changing System Revenue Share (%), by Types 2025 & 2033

- Figure 18: Europe Robot Tool Changing System Revenue (undefined), by Country 2025 & 2033

- Figure 19: Europe Robot Tool Changing System Revenue Share (%), by Country 2025 & 2033

- Figure 20: Middle East & Africa Robot Tool Changing System Revenue (undefined), by Application 2025 & 2033

- Figure 21: Middle East & Africa Robot Tool Changing System Revenue Share (%), by Application 2025 & 2033

- Figure 22: Middle East & Africa Robot Tool Changing System Revenue (undefined), by Types 2025 & 2033

- Figure 23: Middle East & Africa Robot Tool Changing System Revenue Share (%), by Types 2025 & 2033

- Figure 24: Middle East & Africa Robot Tool Changing System Revenue (undefined), by Country 2025 & 2033

- Figure 25: Middle East & Africa Robot Tool Changing System Revenue Share (%), by Country 2025 & 2033

- Figure 26: Asia Pacific Robot Tool Changing System Revenue (undefined), by Application 2025 & 2033

- Figure 27: Asia Pacific Robot Tool Changing System Revenue Share (%), by Application 2025 & 2033

- Figure 28: Asia Pacific Robot Tool Changing System Revenue (undefined), by Types 2025 & 2033

- Figure 29: Asia Pacific Robot Tool Changing System Revenue Share (%), by Types 2025 & 2033

- Figure 30: Asia Pacific Robot Tool Changing System Revenue (undefined), by Country 2025 & 2033

- Figure 31: Asia Pacific Robot Tool Changing System Revenue Share (%), by Country 2025 & 2033

List of Tables

- Table 1: Global Robot Tool Changing System Revenue undefined Forecast, by Region 2020 & 2033

- Table 2: Global Robot Tool Changing System Revenue undefined Forecast, by Application 2020 & 2033

- Table 3: Global Robot Tool Changing System Revenue undefined Forecast, by Types 2020 & 2033

- Table 4: Global Robot Tool Changing System Revenue undefined Forecast, by Region 2020 & 2033

- Table 5: Global Robot Tool Changing System Revenue undefined Forecast, by Application 2020 & 2033

- Table 6: Global Robot Tool Changing System Revenue undefined Forecast, by Types 2020 & 2033

- Table 7: Global Robot Tool Changing System Revenue undefined Forecast, by Country 2020 & 2033

- Table 8: United States Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 9: Canada Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 10: Mexico Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 11: Global Robot Tool Changing System Revenue undefined Forecast, by Application 2020 & 2033

- Table 12: Global Robot Tool Changing System Revenue undefined Forecast, by Types 2020 & 2033

- Table 13: Global Robot Tool Changing System Revenue undefined Forecast, by Country 2020 & 2033

- Table 14: Brazil Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 15: Argentina Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 16: Rest of South America Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 17: Global Robot Tool Changing System Revenue undefined Forecast, by Application 2020 & 2033

- Table 18: Global Robot Tool Changing System Revenue undefined Forecast, by Types 2020 & 2033

- Table 19: Global Robot Tool Changing System Revenue undefined Forecast, by Country 2020 & 2033

- Table 20: United Kingdom Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 21: Germany Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 22: France Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 23: Italy Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 24: Spain Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 25: Russia Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 26: Benelux Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 27: Nordics Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 28: Rest of Europe Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 29: Global Robot Tool Changing System Revenue undefined Forecast, by Application 2020 & 2033

- Table 30: Global Robot Tool Changing System Revenue undefined Forecast, by Types 2020 & 2033

- Table 31: Global Robot Tool Changing System Revenue undefined Forecast, by Country 2020 & 2033

- Table 32: Turkey Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 33: Israel Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 34: GCC Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 35: North Africa Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 36: South Africa Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 37: Rest of Middle East & Africa Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 38: Global Robot Tool Changing System Revenue undefined Forecast, by Application 2020 & 2033

- Table 39: Global Robot Tool Changing System Revenue undefined Forecast, by Types 2020 & 2033

- Table 40: Global Robot Tool Changing System Revenue undefined Forecast, by Country 2020 & 2033

- Table 41: China Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 42: India Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 43: Japan Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 44: South Korea Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 45: ASEAN Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 46: Oceania Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 47: Rest of Asia Pacific Robot Tool Changing System Revenue (undefined) Forecast, by Application 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Robot Tool Changing System?

The projected CAGR is approximately 5.6%.

2. Which companies are prominent players in the Robot Tool Changing System?

Key companies in the market include ATI, Staubli, Schunk, Destaco, Applied Robotics, RSP, AGI, Nitta, Pascal, Carl Kurt Walther, Robotic & Automation Tooling, OBARA Corporation.

3. What are the main segments of the Robot Tool Changing System?

The market segments include Application, Types.

4. Can you provide details about the market size?

The market size is estimated to be USD XXX N/A as of 2022.

5. What are some drivers contributing to market growth?

N/A

6. What are the notable trends driving market growth?

N/A

7. Are there any restraints impacting market growth?

N/A

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 2900.00, USD 4350.00, and USD 5800.00 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in N/A.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Robot Tool Changing System," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Robot Tool Changing System report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Robot Tool Changing System?

To stay informed about further developments, trends, and reports in the Robot Tool Changing System, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

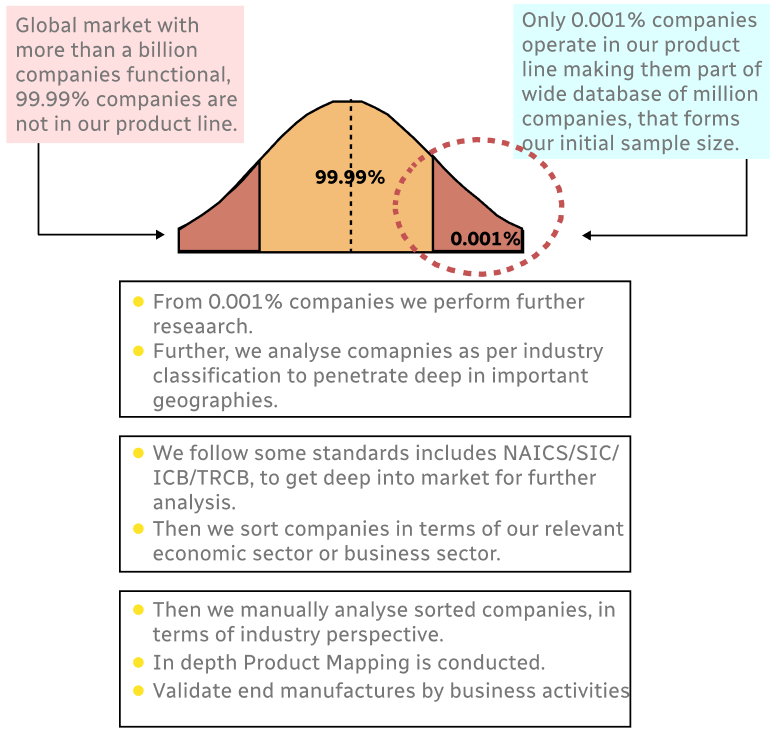

Step 1 - Identification of Relevant Samples Size from Population Database

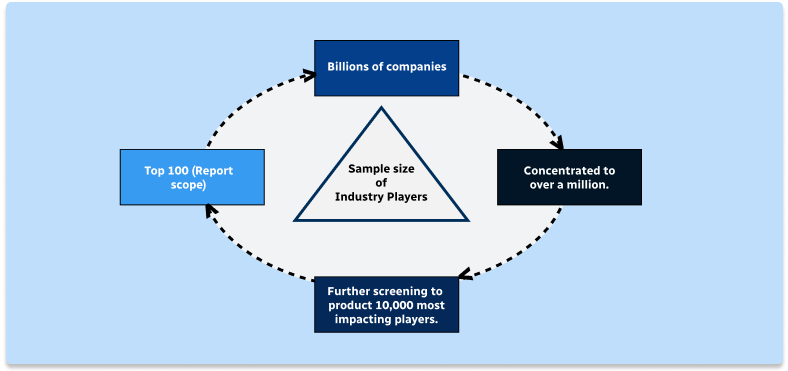

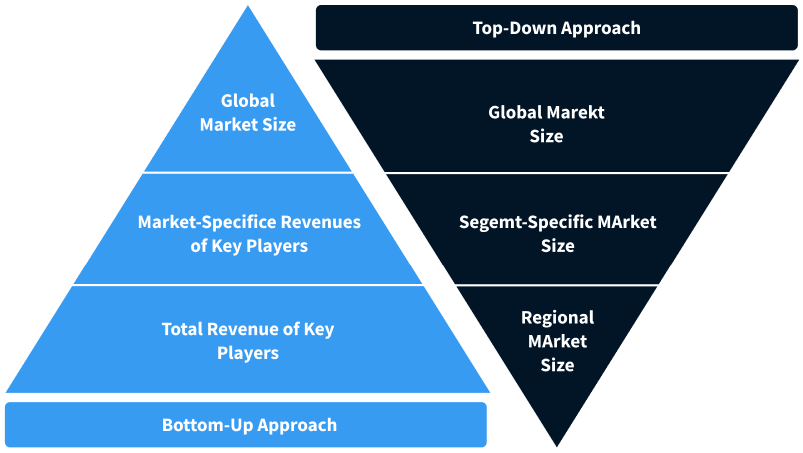

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

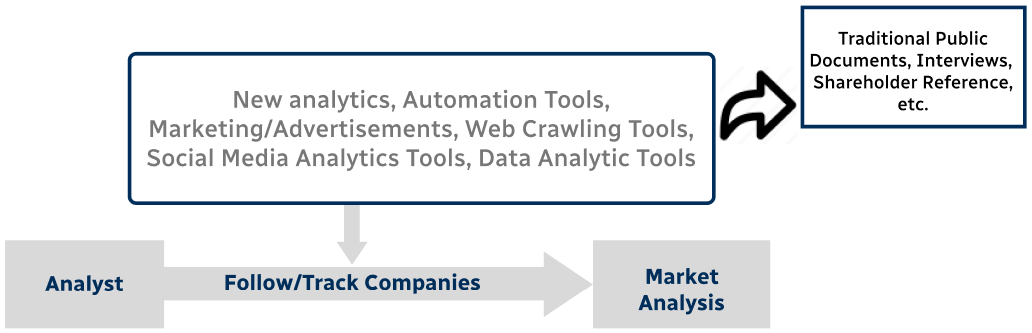

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence