Key Insights

The 3D printing market for the automotive sector is poised for substantial growth, driven by the critical need for lightweight components, enhanced customization, and accelerated rapid prototyping capabilities. Projections indicate a Compound Annual Growth Rate (CAGR) of 14.8%, with the market size estimated at 5.93 billion by 2025. This expansion is reshaping automotive manufacturing and supply chains through several key advancements. Firstly, additive manufacturing enables the creation of complex geometries and intricate designs unattainable with traditional methods, leading to improved vehicle performance, reduced weight, and increased fuel efficiency. Secondly, the rapid prototyping facilitated by 3D printing significantly shortens development cycles and time-to-market, a vital competitive edge in the automotive industry. Lastly, the growing demand for personalized vehicles and custom features aligns perfectly with 3D printing's capacity for on-demand, highly specialized part production, driving its adoption across various vehicle segments. The market encompasses diverse applications, including metal, polymer, and ceramic components for both production and R&D. Leading technologies such as SLS, SLA, DLP, EBM, SLM, and FDM are utilized to meet specific performance and cost requirements. Key industry players, including 3D Systems, Stratasys, and EOS, are at the forefront of innovation, propelling market expansion and advancements in materials and printing techniques.

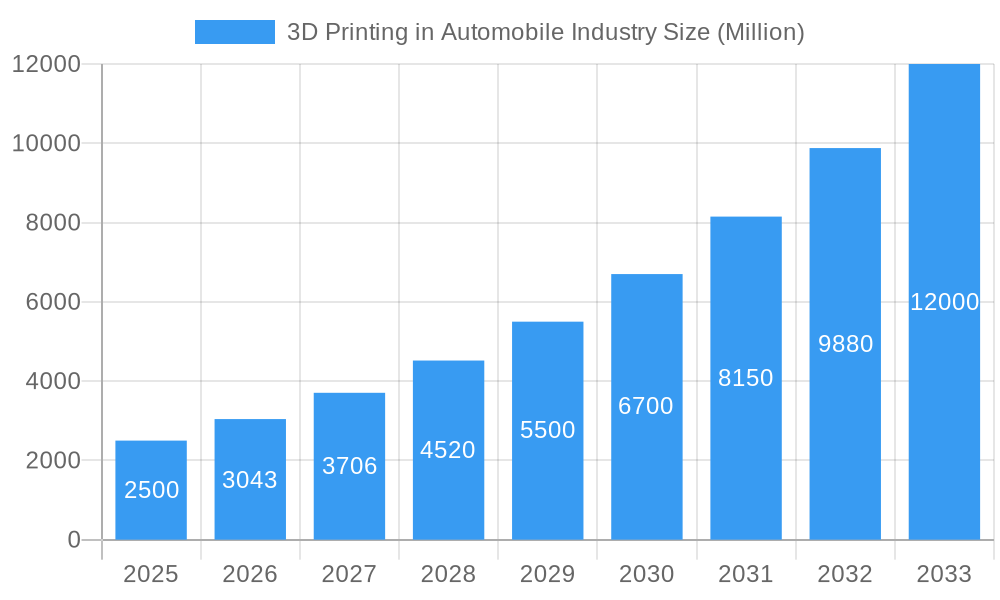

3D Printing in Automobile Industry Market Size (In Billion)

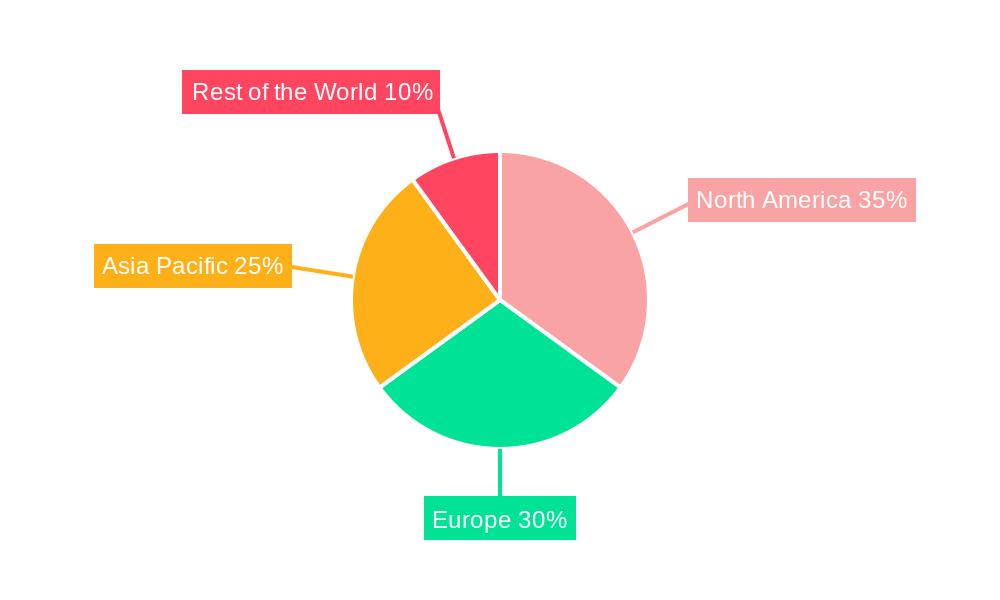

Geographically, North America and Europe are expected to lead initial market share, with rapid growth anticipated in the Asia-Pacific region due to expanding automotive manufacturing hubs in China and India. Potential challenges, such as the initial investment costs for 3D printing equipment and the requirement for specialized materials and skilled labor, are outweighed by the exceptionally positive long-term outlook. Continuous technological evolution, coupled with ongoing research into novel materials and applications, guarantees sustained growth and widespread integration throughout the forecast period. The automotive industry's increasing emphasis on sustainability and emission reduction further highlights 3D printing's potential to optimize production processes and contribute to the development of more environmentally conscious vehicles.

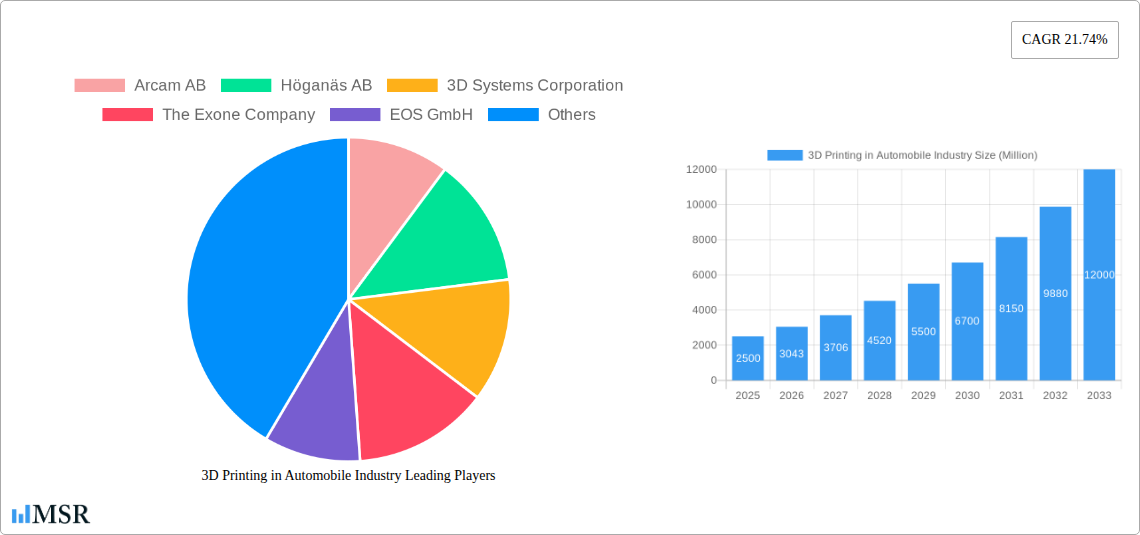

3D Printing in Automobile Industry Company Market Share

3D Printing in the Automobile Industry: A Comprehensive Market Report (2019-2033)

This in-depth report provides a comprehensive analysis of the 3D printing market within the automotive industry, covering market dynamics, key segments, leading players, and future growth opportunities. The report utilizes data from 2019-2024 (historical period), with a focus on 2025 (base and estimated year) and forecasts extending to 2033. Expect detailed insights into market size (in Millions of USD), CAGR, and major industry trends impacting this rapidly evolving sector.

3D Printing in Automobile Industry Market Concentration & Dynamics

The 3D printing market in the automotive industry is characterized by a moderately concentrated landscape, with several key players holding significant market share. However, the market is also witnessing considerable innovation and diversification, driven by technological advancements and increasing adoption across various applications. The regulatory framework, while still evolving, is generally supportive of additive manufacturing, fostering growth. Substitute products, such as traditional casting and machining, remain competitive, particularly for high-volume production. End-user trends indicate a shift towards customized and lightweight components, driving demand for 3D printing technologies. Mergers and acquisitions (M&A) activities are frequent, reflecting industry consolidation and strategic expansion. Key players like Stratasys Ltd. have been actively involved in acquisitions to strengthen their market position and broaden their material and technology portfolios. In 2022 alone, several significant M&A deals contributed to market consolidation, with a projected xx Million USD in deal value. The market share of the top 5 players is estimated at xx%, indicating a moderately concentrated market.

3D Printing in Automobile Industry Industry Insights & Trends

The global 3D printing market in the automotive sector is experiencing robust growth, driven by several key factors. The market size was valued at xx Million USD in 2024 and is projected to reach xx Million USD by 2033, exhibiting a CAGR of xx%. Several factors contribute to this growth trajectory: the increasing demand for lightweight vehicles to improve fuel efficiency; the need for customized and complex components that traditional manufacturing methods struggle to produce efficiently; the rising adoption of additive manufacturing for prototyping and rapid tooling; and the continuous advancements in 3D printing technologies, materials, and software. Technological disruptions, such as the emergence of new materials with enhanced properties and improved printing speeds, are further accelerating market expansion. Furthermore, evolving consumer preferences towards personalized vehicles are creating opportunities for customized component production using 3D printing.

Key Markets & Segments Leading 3D Printing in Automobile Industry

Dominant Region: North America is currently the leading region in the automotive 3D printing market, driven by high technological advancements, substantial investments in R&D, and strong automotive manufacturing base. Europe and Asia-Pacific are also significant markets exhibiting robust growth.

Dominant Segment (By Material Type): Metal 3D printing holds the largest market share due to its suitability for high-strength and durable automotive components. Polymer materials are also widely used, especially for prototyping and tooling applications. Ceramic 3D printing holds a smaller share but is growing rapidly due to its suitability for specific high-temperature applications.

Dominant Segment (By Application Type): Prototyping and R&D constitute a large part of the current market, but the Production segment is expected to grow rapidly in the coming years, driven by the cost-effectiveness and efficiency of 3D printing for manufacturing low-volume, high-value components.

Dominant Segment (By Technology Type): Selective Laser Melting (SLM) and Electronic Beam Melting (EBM) dominate the metal 3D printing segment, while Fused Deposition Modeling (FDM) is prevalent for polymer applications. SLS is also widely used for both polymer and metal parts.

Dominant Segment (By Component Type): Hardware components currently comprise the most significant portion of the market, followed by software and services which are expected to grow significantly.

Drivers: Strong economic growth in major automotive markets, increased government investments in R&D and infrastructure, and the emergence of new technologies.

3D Printing in Automobile Industry Product Developments

Recent advancements in 3D printing technologies have led to the development of high-performance materials with improved mechanical properties, enabling the creation of lighter, stronger, and more complex automotive components. The introduction of new software solutions for design optimization and process control has further enhanced the efficiency and precision of 3D printing. These advancements are providing manufacturers with competitive edges by reducing production costs, lead times, and material waste, while also unlocking new design possibilities.

Challenges in the 3D Printing in Automobile Industry Market

The 3D printing industry faces challenges such as high initial investment costs for equipment, limited material options compared to traditional manufacturing processes, and concerns about the scalability and repeatability of production for large volumes. Supply chain disruptions and the need for skilled labor also pose significant obstacles. The regulatory environment, though generally supportive, still needs further clarity in some regions, leading to uncertainties for manufacturers. Furthermore, intense competition among existing 3D printing companies and other manufacturing technologies presents a continuous challenge.

Forces Driving 3D Printing in Automobile Industry Growth

Several factors are accelerating the growth of 3D printing in the automotive industry. Technological advancements like faster printing speeds, enhanced material properties, and improved software solutions are reducing costs and improving efficiency. Government incentives and policies supporting additive manufacturing are fostering innovation and adoption. The increasing demand for lightweight and customized components is driving the need for flexible and efficient manufacturing processes like 3D printing. The automotive industry's focus on sustainability, with 3D printing offering reduced material waste, is a key catalyst for growth.

Long-Term Growth Catalysts in 3D Printing in Automobile Industry Market

Long-term growth in this market hinges on ongoing material innovation, including the development of more sustainable and high-performance materials. Strategic partnerships and collaborations between 3D printing companies and automotive manufacturers will play a crucial role in accelerating technology adoption. The expansion into new applications, such as personalized vehicle customization and the production of intricate internal engine components, will unlock significant market potential. Furthermore, advancements in automation and artificial intelligence for optimizing 3D printing processes will drive efficiency and reduce production costs.

Emerging Opportunities in 3D Printing in Automobile Industry

Emerging opportunities include the development of new materials specifically tailored for automotive applications, such as high-strength composites and bio-based polymers. The integration of 3D printing into existing manufacturing workflows is crucial for greater market penetration. The growing demand for mass customization, especially in luxury and performance vehicles, offers significant opportunities for 3D printing. The expansion into new markets such as the production of tooling and jigs for automotive manufacturing is another avenue for growth.

Leading Players in the 3D Printing in Automobile Industry Sector

- Arcam AB

- Höganäs AB

- 3D Systems Corporation

- The Exone Company

- EOS GmbH

- Voxeljet AG

- Materialise NV

- Moog Inc

- Ultimaker BV

- Stratasys Ltd

- Envisiontec GmbH

Key Milestones in 3D Printing in Automobile Industry Industry

November 2022: Desktop Metal secures a USD 9 Million order for binder jet additive manufacturing systems from a major German car manufacturer for mass production of powertrain components. This signifies a major step towards wider adoption of 3D printing in high-volume automotive production.

November 2022: 3D Systems and ALM partner to expand access to industry-leading 3D printing materials, broadening the range of materials available for SLS technologies. This expands the applications and capabilities of SLS within the automotive industry.

September 2022: Stratasys Ltd. completes the merger of MakerBot and Ultimaker, creating a leading force in desktop 3D printing. This merger enhances the market presence and technological capabilities of the combined entity.

September 2022: Materialise N.V. acquires Identify3D, enhancing its additive manufacturing platform's security features. This bolsters the trust and adoption of Materialise's platform within sensitive automotive supply chains.

August 2022: Stratasys Ltd. acquires Covestro AG's additive materials manufacturing business, expanding its material portfolio and accelerating innovation in next-generation materials. This strategic move strengthens Stratasys' position within the material supply chain for 3D printing.

August 2022: Voxeljet AG completes a sale-leaseback agreement, generating USD 26.78 Million in proceeds. This financial maneuver improves Voxeljet's financial flexibility, enabling further investments in R&D and expansion.

Strategic Outlook for 3D Printing in Automobile Industry Market

The future of 3D printing in the automotive industry is bright, with significant growth potential driven by continued technological advancements, increasing demand for lightweight and customized components, and growing adoption in high-volume production. Strategic partnerships between automotive manufacturers and 3D printing companies will accelerate the development and implementation of innovative solutions. The focus on sustainability and the ability of 3D printing to reduce material waste and energy consumption will further drive its adoption. The market is expected to witness substantial expansion across various automotive segments, including the production of both prototypes and final components, solidifying 3D printing's role in the future of automotive manufacturing.

3D Printing in Automobile Industry Segmentation

-

1. Technology Type

- 1.1. Selective Laser Sintering (SLS)

- 1.2. Stereo Lithography (SLA)

- 1.3. Digital Light Processing (DLP)

- 1.4. Electronic Beam Melting (EBM)

- 1.5. Selective Laser Melting (SLM)

- 1.6. Fused Deposition Modeling (FDM)

-

2. Component Type

- 2.1. Hardware

- 2.2. Software

- 2.3. Service

-

3. Material Type

- 3.1. Metal

- 3.2. Polymer

- 3.3. Ceramic

-

4. Application Type

- 4.1. Production

- 4.2. Prototyping/R&D

3D Printing in Automobile Industry Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Rest of North America

-

2. Europe

- 2.1. Germany

- 2.2. United Kingdom

- 2.3. France

- 2.4. Rest of Europe

-

3. Asia Pacific

- 3.1. China

- 3.2. Japan

- 3.3. India

- 3.4. Rest of Asia Pacific

-

4. Rest of the World

- 4.1. Brazil

- 4.2. Argentina

- 4.3. Other Countries

3D Printing in Automobile Industry Regional Market Share

Geographic Coverage of 3D Printing in Automobile Industry

3D Printing in Automobile Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 14.8% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Increasingly Focused On Lightweighting Vehicles

- 3.3. Market Restrains

- 3.3.1. High Production Cost

- 3.4. Market Trends

- 3.4.1. Growing Adoption of Fused Deposition Modeling Technology

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global 3D Printing in Automobile Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Technology Type

- 5.1.1. Selective Laser Sintering (SLS)

- 5.1.2. Stereo Lithography (SLA)

- 5.1.3. Digital Light Processing (DLP)

- 5.1.4. Electronic Beam Melting (EBM)

- 5.1.5. Selective Laser Melting (SLM)

- 5.1.6. Fused Deposition Modeling (FDM)

- 5.2. Market Analysis, Insights and Forecast - by Component Type

- 5.2.1. Hardware

- 5.2.2. Software

- 5.2.3. Service

- 5.3. Market Analysis, Insights and Forecast - by Material Type

- 5.3.1. Metal

- 5.3.2. Polymer

- 5.3.3. Ceramic

- 5.4. Market Analysis, Insights and Forecast - by Application Type

- 5.4.1. Production

- 5.4.2. Prototyping/R&D

- 5.5. Market Analysis, Insights and Forecast - by Region

- 5.5.1. North America

- 5.5.2. Europe

- 5.5.3. Asia Pacific

- 5.5.4. Rest of the World

- 5.1. Market Analysis, Insights and Forecast - by Technology Type

- 6. North America 3D Printing in Automobile Industry Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Technology Type

- 6.1.1. Selective Laser Sintering (SLS)

- 6.1.2. Stereo Lithography (SLA)

- 6.1.3. Digital Light Processing (DLP)

- 6.1.4. Electronic Beam Melting (EBM)

- 6.1.5. Selective Laser Melting (SLM)

- 6.1.6. Fused Deposition Modeling (FDM)

- 6.2. Market Analysis, Insights and Forecast - by Component Type

- 6.2.1. Hardware

- 6.2.2. Software

- 6.2.3. Service

- 6.3. Market Analysis, Insights and Forecast - by Material Type

- 6.3.1. Metal

- 6.3.2. Polymer

- 6.3.3. Ceramic

- 6.4. Market Analysis, Insights and Forecast - by Application Type

- 6.4.1. Production

- 6.4.2. Prototyping/R&D

- 6.1. Market Analysis, Insights and Forecast - by Technology Type

- 7. Europe 3D Printing in Automobile Industry Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Technology Type

- 7.1.1. Selective Laser Sintering (SLS)

- 7.1.2. Stereo Lithography (SLA)

- 7.1.3. Digital Light Processing (DLP)

- 7.1.4. Electronic Beam Melting (EBM)

- 7.1.5. Selective Laser Melting (SLM)

- 7.1.6. Fused Deposition Modeling (FDM)

- 7.2. Market Analysis, Insights and Forecast - by Component Type

- 7.2.1. Hardware

- 7.2.2. Software

- 7.2.3. Service

- 7.3. Market Analysis, Insights and Forecast - by Material Type

- 7.3.1. Metal

- 7.3.2. Polymer

- 7.3.3. Ceramic

- 7.4. Market Analysis, Insights and Forecast - by Application Type

- 7.4.1. Production

- 7.4.2. Prototyping/R&D

- 7.1. Market Analysis, Insights and Forecast - by Technology Type

- 8. Asia Pacific 3D Printing in Automobile Industry Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Technology Type

- 8.1.1. Selective Laser Sintering (SLS)

- 8.1.2. Stereo Lithography (SLA)

- 8.1.3. Digital Light Processing (DLP)

- 8.1.4. Electronic Beam Melting (EBM)

- 8.1.5. Selective Laser Melting (SLM)

- 8.1.6. Fused Deposition Modeling (FDM)

- 8.2. Market Analysis, Insights and Forecast - by Component Type

- 8.2.1. Hardware

- 8.2.2. Software

- 8.2.3. Service

- 8.3. Market Analysis, Insights and Forecast - by Material Type

- 8.3.1. Metal

- 8.3.2. Polymer

- 8.3.3. Ceramic

- 8.4. Market Analysis, Insights and Forecast - by Application Type

- 8.4.1. Production

- 8.4.2. Prototyping/R&D

- 8.1. Market Analysis, Insights and Forecast - by Technology Type

- 9. Rest of the World 3D Printing in Automobile Industry Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Technology Type

- 9.1.1. Selective Laser Sintering (SLS)

- 9.1.2. Stereo Lithography (SLA)

- 9.1.3. Digital Light Processing (DLP)

- 9.1.4. Electronic Beam Melting (EBM)

- 9.1.5. Selective Laser Melting (SLM)

- 9.1.6. Fused Deposition Modeling (FDM)

- 9.2. Market Analysis, Insights and Forecast - by Component Type

- 9.2.1. Hardware

- 9.2.2. Software

- 9.2.3. Service

- 9.3. Market Analysis, Insights and Forecast - by Material Type

- 9.3.1. Metal

- 9.3.2. Polymer

- 9.3.3. Ceramic

- 9.4. Market Analysis, Insights and Forecast - by Application Type

- 9.4.1. Production

- 9.4.2. Prototyping/R&D

- 9.1. Market Analysis, Insights and Forecast - by Technology Type

- 10. Competitive Analysis

- 10.1. Global Market Share Analysis 2025

- 10.2. Company Profiles

- 10.2.1 Arcam AB

- 10.2.1.1. Overview

- 10.2.1.2. Products

- 10.2.1.3. SWOT Analysis

- 10.2.1.4. Recent Developments

- 10.2.1.5. Financials (Based on Availability)

- 10.2.2 Höganäs AB

- 10.2.2.1. Overview

- 10.2.2.2. Products

- 10.2.2.3. SWOT Analysis

- 10.2.2.4. Recent Developments

- 10.2.2.5. Financials (Based on Availability)

- 10.2.3 3D Systems Corporation

- 10.2.3.1. Overview

- 10.2.3.2. Products

- 10.2.3.3. SWOT Analysis

- 10.2.3.4. Recent Developments

- 10.2.3.5. Financials (Based on Availability)

- 10.2.4 The Exone Company

- 10.2.4.1. Overview

- 10.2.4.2. Products

- 10.2.4.3. SWOT Analysis

- 10.2.4.4. Recent Developments

- 10.2.4.5. Financials (Based on Availability)

- 10.2.5 EOS GmbH

- 10.2.5.1. Overview

- 10.2.5.2. Products

- 10.2.5.3. SWOT Analysis

- 10.2.5.4. Recent Developments

- 10.2.5.5. Financials (Based on Availability)

- 10.2.6 Voxeljet AG

- 10.2.6.1. Overview

- 10.2.6.2. Products

- 10.2.6.3. SWOT Analysis

- 10.2.6.4. Recent Developments

- 10.2.6.5. Financials (Based on Availability)

- 10.2.7 Materialise NV

- 10.2.7.1. Overview

- 10.2.7.2. Products

- 10.2.7.3. SWOT Analysis

- 10.2.7.4. Recent Developments

- 10.2.7.5. Financials (Based on Availability)

- 10.2.8 Moog Inc *List Not Exhaustive

- 10.2.8.1. Overview

- 10.2.8.2. Products

- 10.2.8.3. SWOT Analysis

- 10.2.8.4. Recent Developments

- 10.2.8.5. Financials (Based on Availability)

- 10.2.9 Ultimaker BV

- 10.2.9.1. Overview

- 10.2.9.2. Products

- 10.2.9.3. SWOT Analysis

- 10.2.9.4. Recent Developments

- 10.2.9.5. Financials (Based on Availability)

- 10.2.10 Stratasys Ltd

- 10.2.10.1. Overview

- 10.2.10.2. Products

- 10.2.10.3. SWOT Analysis

- 10.2.10.4. Recent Developments

- 10.2.10.5. Financials (Based on Availability)

- 10.2.11 Envisiontec GmbH

- 10.2.11.1. Overview

- 10.2.11.2. Products

- 10.2.11.3. SWOT Analysis

- 10.2.11.4. Recent Developments

- 10.2.11.5. Financials (Based on Availability)

- 10.2.1 Arcam AB

List of Figures

- Figure 1: Global 3D Printing in Automobile Industry Revenue Breakdown (billion, %) by Region 2025 & 2033

- Figure 2: North America 3D Printing in Automobile Industry Revenue (billion), by Technology Type 2025 & 2033

- Figure 3: North America 3D Printing in Automobile Industry Revenue Share (%), by Technology Type 2025 & 2033

- Figure 4: North America 3D Printing in Automobile Industry Revenue (billion), by Component Type 2025 & 2033

- Figure 5: North America 3D Printing in Automobile Industry Revenue Share (%), by Component Type 2025 & 2033

- Figure 6: North America 3D Printing in Automobile Industry Revenue (billion), by Material Type 2025 & 2033

- Figure 7: North America 3D Printing in Automobile Industry Revenue Share (%), by Material Type 2025 & 2033

- Figure 8: North America 3D Printing in Automobile Industry Revenue (billion), by Application Type 2025 & 2033

- Figure 9: North America 3D Printing in Automobile Industry Revenue Share (%), by Application Type 2025 & 2033

- Figure 10: North America 3D Printing in Automobile Industry Revenue (billion), by Country 2025 & 2033

- Figure 11: North America 3D Printing in Automobile Industry Revenue Share (%), by Country 2025 & 2033

- Figure 12: Europe 3D Printing in Automobile Industry Revenue (billion), by Technology Type 2025 & 2033

- Figure 13: Europe 3D Printing in Automobile Industry Revenue Share (%), by Technology Type 2025 & 2033

- Figure 14: Europe 3D Printing in Automobile Industry Revenue (billion), by Component Type 2025 & 2033

- Figure 15: Europe 3D Printing in Automobile Industry Revenue Share (%), by Component Type 2025 & 2033

- Figure 16: Europe 3D Printing in Automobile Industry Revenue (billion), by Material Type 2025 & 2033

- Figure 17: Europe 3D Printing in Automobile Industry Revenue Share (%), by Material Type 2025 & 2033

- Figure 18: Europe 3D Printing in Automobile Industry Revenue (billion), by Application Type 2025 & 2033

- Figure 19: Europe 3D Printing in Automobile Industry Revenue Share (%), by Application Type 2025 & 2033

- Figure 20: Europe 3D Printing in Automobile Industry Revenue (billion), by Country 2025 & 2033

- Figure 21: Europe 3D Printing in Automobile Industry Revenue Share (%), by Country 2025 & 2033

- Figure 22: Asia Pacific 3D Printing in Automobile Industry Revenue (billion), by Technology Type 2025 & 2033

- Figure 23: Asia Pacific 3D Printing in Automobile Industry Revenue Share (%), by Technology Type 2025 & 2033

- Figure 24: Asia Pacific 3D Printing in Automobile Industry Revenue (billion), by Component Type 2025 & 2033

- Figure 25: Asia Pacific 3D Printing in Automobile Industry Revenue Share (%), by Component Type 2025 & 2033

- Figure 26: Asia Pacific 3D Printing in Automobile Industry Revenue (billion), by Material Type 2025 & 2033

- Figure 27: Asia Pacific 3D Printing in Automobile Industry Revenue Share (%), by Material Type 2025 & 2033

- Figure 28: Asia Pacific 3D Printing in Automobile Industry Revenue (billion), by Application Type 2025 & 2033

- Figure 29: Asia Pacific 3D Printing in Automobile Industry Revenue Share (%), by Application Type 2025 & 2033

- Figure 30: Asia Pacific 3D Printing in Automobile Industry Revenue (billion), by Country 2025 & 2033

- Figure 31: Asia Pacific 3D Printing in Automobile Industry Revenue Share (%), by Country 2025 & 2033

- Figure 32: Rest of the World 3D Printing in Automobile Industry Revenue (billion), by Technology Type 2025 & 2033

- Figure 33: Rest of the World 3D Printing in Automobile Industry Revenue Share (%), by Technology Type 2025 & 2033

- Figure 34: Rest of the World 3D Printing in Automobile Industry Revenue (billion), by Component Type 2025 & 2033

- Figure 35: Rest of the World 3D Printing in Automobile Industry Revenue Share (%), by Component Type 2025 & 2033

- Figure 36: Rest of the World 3D Printing in Automobile Industry Revenue (billion), by Material Type 2025 & 2033

- Figure 37: Rest of the World 3D Printing in Automobile Industry Revenue Share (%), by Material Type 2025 & 2033

- Figure 38: Rest of the World 3D Printing in Automobile Industry Revenue (billion), by Application Type 2025 & 2033

- Figure 39: Rest of the World 3D Printing in Automobile Industry Revenue Share (%), by Application Type 2025 & 2033

- Figure 40: Rest of the World 3D Printing in Automobile Industry Revenue (billion), by Country 2025 & 2033

- Figure 41: Rest of the World 3D Printing in Automobile Industry Revenue Share (%), by Country 2025 & 2033

List of Tables

- Table 1: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Technology Type 2020 & 2033

- Table 2: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Component Type 2020 & 2033

- Table 3: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Material Type 2020 & 2033

- Table 4: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Application Type 2020 & 2033

- Table 5: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Region 2020 & 2033

- Table 6: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Technology Type 2020 & 2033

- Table 7: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Component Type 2020 & 2033

- Table 8: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Material Type 2020 & 2033

- Table 9: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Application Type 2020 & 2033

- Table 10: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Country 2020 & 2033

- Table 11: United States 3D Printing in Automobile Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 12: Canada 3D Printing in Automobile Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 13: Rest of North America 3D Printing in Automobile Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 14: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Technology Type 2020 & 2033

- Table 15: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Component Type 2020 & 2033

- Table 16: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Material Type 2020 & 2033

- Table 17: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Application Type 2020 & 2033

- Table 18: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Country 2020 & 2033

- Table 19: Germany 3D Printing in Automobile Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 20: United Kingdom 3D Printing in Automobile Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 21: France 3D Printing in Automobile Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 22: Rest of Europe 3D Printing in Automobile Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 23: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Technology Type 2020 & 2033

- Table 24: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Component Type 2020 & 2033

- Table 25: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Material Type 2020 & 2033

- Table 26: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Application Type 2020 & 2033

- Table 27: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Country 2020 & 2033

- Table 28: China 3D Printing in Automobile Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 29: Japan 3D Printing in Automobile Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 30: India 3D Printing in Automobile Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 31: Rest of Asia Pacific 3D Printing in Automobile Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 32: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Technology Type 2020 & 2033

- Table 33: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Component Type 2020 & 2033

- Table 34: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Material Type 2020 & 2033

- Table 35: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Application Type 2020 & 2033

- Table 36: Global 3D Printing in Automobile Industry Revenue billion Forecast, by Country 2020 & 2033

- Table 37: Brazil 3D Printing in Automobile Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 38: Argentina 3D Printing in Automobile Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 39: Other Countries 3D Printing in Automobile Industry Revenue (billion) Forecast, by Application 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the 3D Printing in Automobile Industry?

The projected CAGR is approximately 14.8%.

2. Which companies are prominent players in the 3D Printing in Automobile Industry?

Key companies in the market include Arcam AB, Höganäs AB, 3D Systems Corporation, The Exone Company, EOS GmbH, Voxeljet AG, Materialise NV, Moog Inc *List Not Exhaustive, Ultimaker BV, Stratasys Ltd, Envisiontec GmbH.

3. What are the main segments of the 3D Printing in Automobile Industry?

The market segments include Technology Type, Component Type, Material Type, Application Type.

4. Can you provide details about the market size?

The market size is estimated to be USD 5.93 billion as of 2022.

5. What are some drivers contributing to market growth?

Increasingly Focused On Lightweighting Vehicles.

6. What are the notable trends driving market growth?

Growing Adoption of Fused Deposition Modeling Technology.

7. Are there any restraints impacting market growth?

High Production Cost.

8. Can you provide examples of recent developments in the market?

November 2022- Desktop Metal, the parent company of ExOne, announced that it had won a USD 9 million order from one of the major German car manufacturers for binder jet additive manufacturing systems used for the mass production of powertrain components.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in billion.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "3D Printing in Automobile Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the 3D Printing in Automobile Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the 3D Printing in Automobile Industry?

To stay informed about further developments, trends, and reports in the 3D Printing in Automobile Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

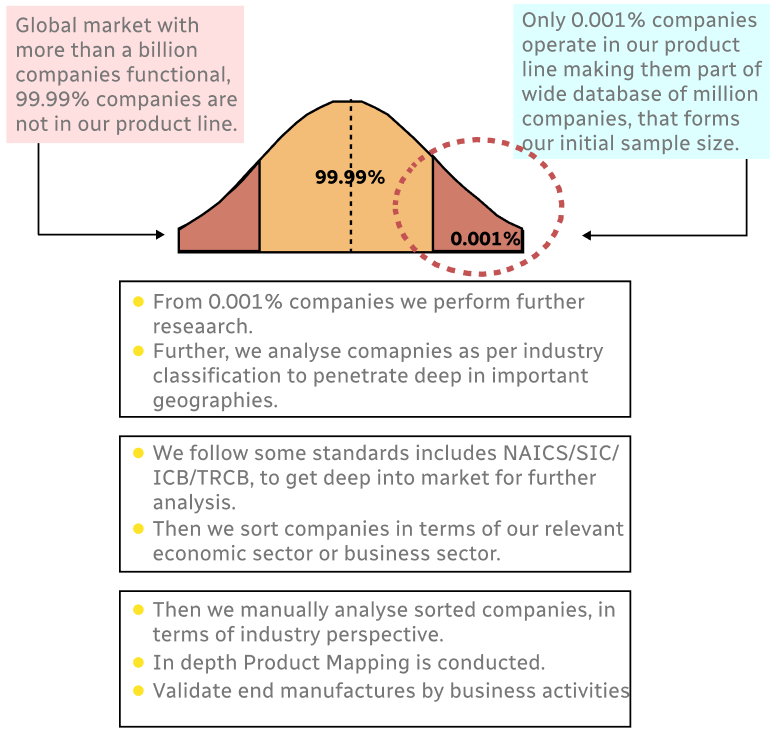

Step 1 - Identification of Relevant Samples Size from Population Database

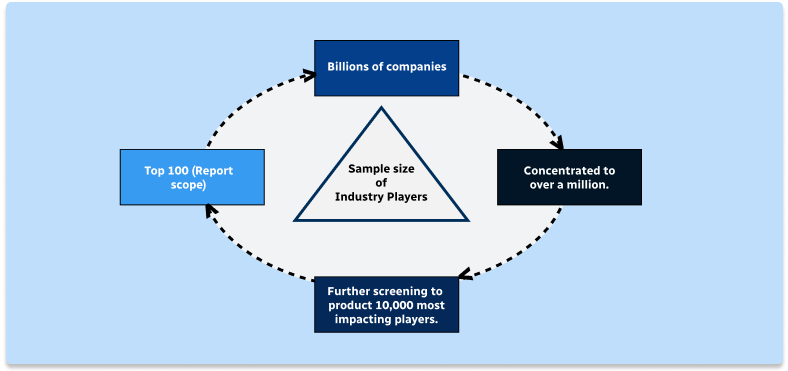

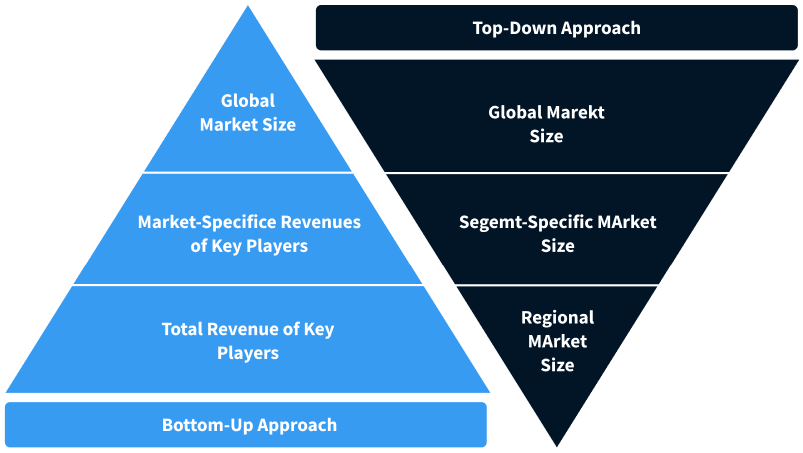

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

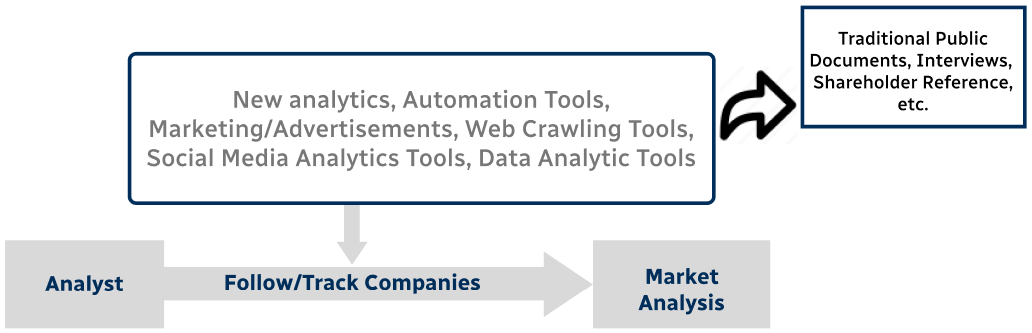

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence