Key Insights

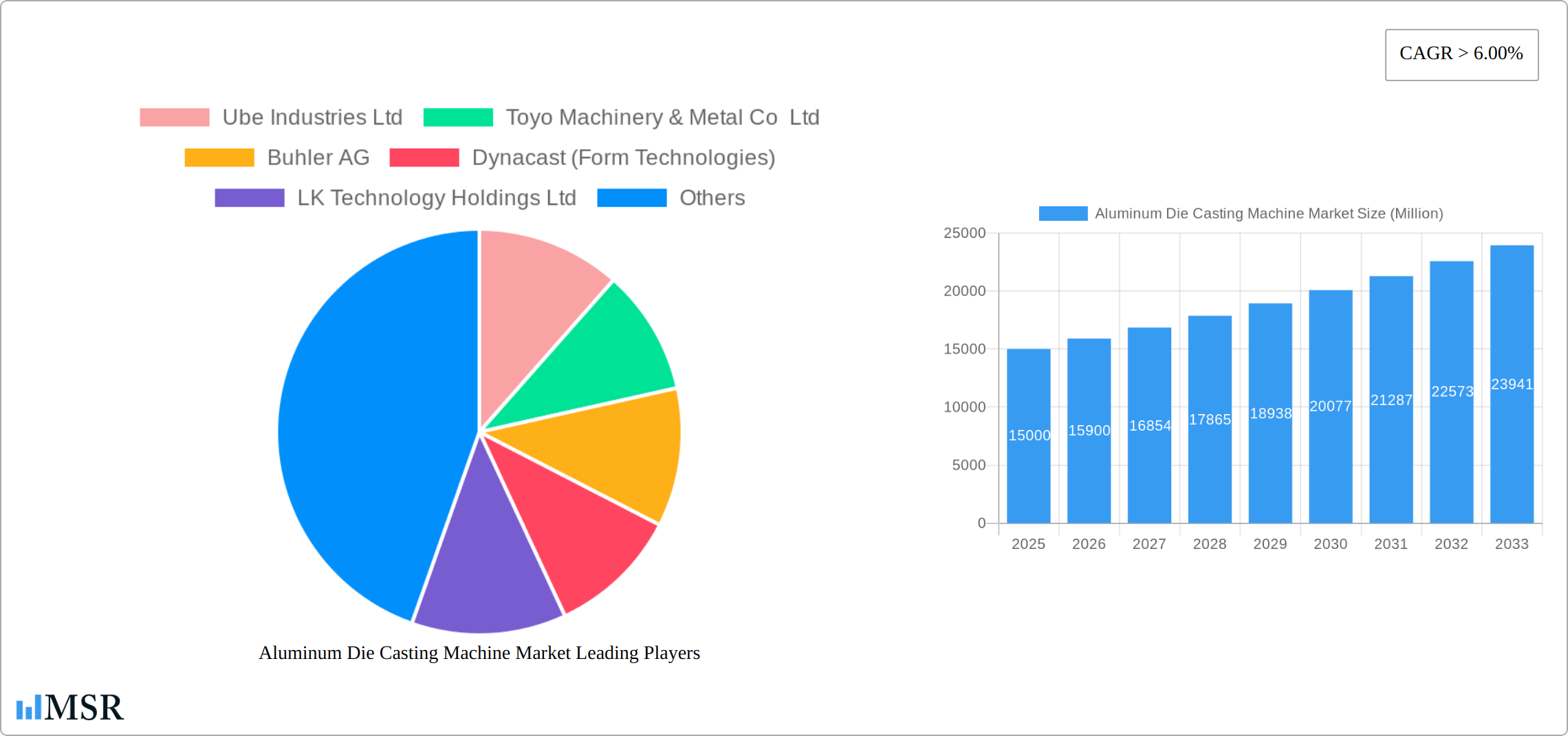

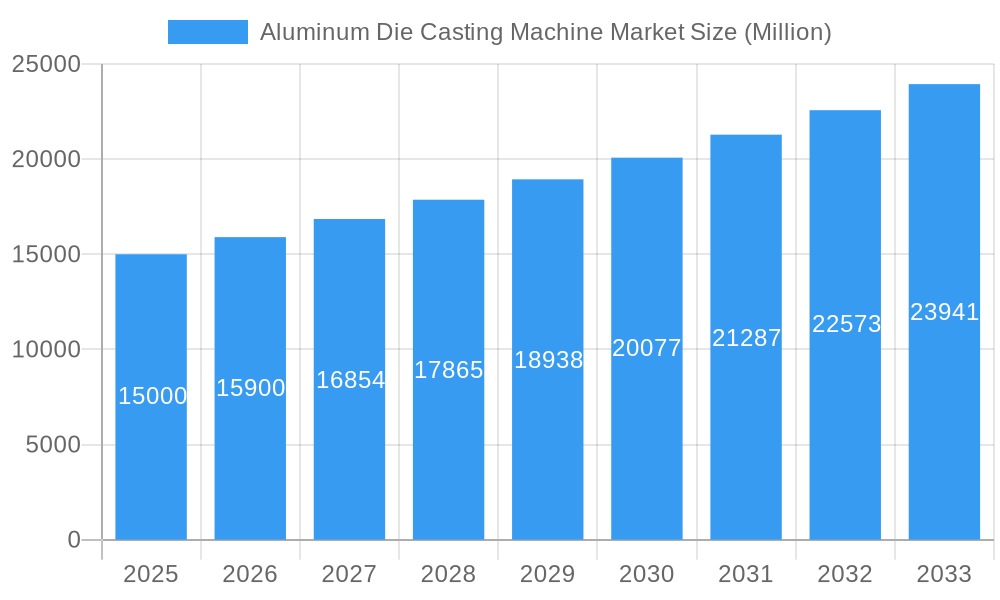

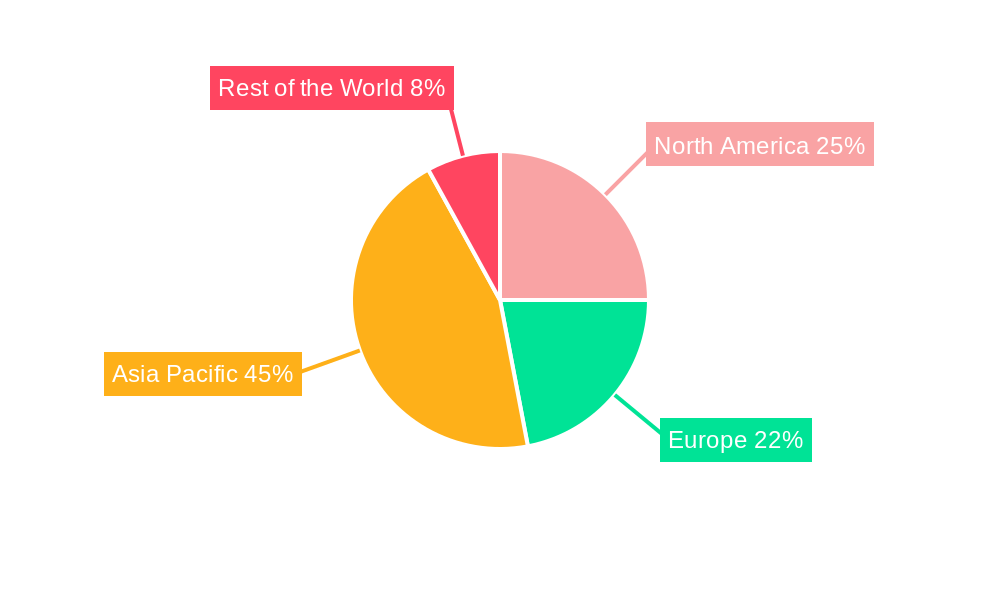

The global aluminum die casting machine market is poised for significant expansion, driven by escalating demand for lightweight, high-strength components across key industries. Projections indicate a robust growth trajectory, with a projected compound annual growth rate (CAGR) of 6.16%. The market, valued at 3.83 billion in the base year of 2025, is expected to witness sustained growth through 2033. Key growth catalysts include the automotive sector's increasing adoption of electric vehicles (EVs), necessitating lighter components for enhanced battery range and efficiency. The 3C industry (computers, communication, and consumer electronics) also significantly contributes, requiring high-precision aluminum die castings for advanced devices. Technological advancements in machine efficiency, casting quality, and automation further propel market growth. While challenges such as rising raw material costs and potential supply chain disruptions exist, innovation and sustained demand from critical sectors maintain a positive market outlook. Market segmentation by machine type, industry, and raw material offers insights into specific dynamics and opportunities. Leading players like Ube Industries, Toyo Machinery, and Buhler AG compete on technological superiority, cost-effectiveness, and customer support. The Asia-Pacific region, particularly China and India, demonstrates strong growth due to expanding manufacturing and automotive investments, followed by North America and Europe. Sustainable manufacturing practices and the development of advanced aluminum alloys will shape the market's future.

Aluminum Die Casting Machine Market Market Size (In Billion)

The competitive landscape is characterized by established and emerging companies vying for market share. Successful strategies emphasize customized solutions, advanced automation, and energy-efficient machine development. The integration of Industry 4.0 principles, including data analytics and predictive maintenance, is set to enhance efficiency and minimize downtime. Strategic partnerships and collaborations are crucial for technological access and market expansion. Navigating economic fluctuations, geopolitical factors, and continuous technological innovation will determine the market's future success. The market is anticipated to expand over the next decade, with substantial growth potential in developing economies.

Aluminum Die Casting Machine Market Company Market Share

Aluminum Die Casting Machine Market: A Comprehensive Report (2019-2033)

This comprehensive report provides a detailed analysis of the global Aluminum Die Casting Machine market, offering actionable insights for industry stakeholders. The study period spans from 2019 to 2033, with 2025 serving as the base and estimated year. The report meticulously examines market dynamics, key segments, leading players, and future growth prospects, providing a holistic understanding of this dynamic sector. The market is expected to reach xx Million by 2033, registering a CAGR of xx% during the forecast period (2025-2033).

Aluminum Die Casting Machine Market Concentration & Dynamics

The Aluminum Die Casting Machine market exhibits a moderately concentrated landscape, with a few major players holding significant market share. However, the presence of several regional and specialized manufacturers fosters competition. Innovation plays a crucial role, with continuous advancements in machine design, automation, and materials contributing to market growth. Regulatory frameworks, particularly those concerning environmental regulations and safety standards, significantly influence market dynamics. Substitute products, such as plastic injection molding and other metal casting techniques, pose a competitive challenge. End-user trends, especially the increasing demand for lightweight components in the automotive and 3C industries, drive market expansion. Mergers and acquisitions (M&A) activity has been relatively consistent, with xx M&A deals recorded in the past five years, signifying a strategic approach to market consolidation and expansion.

- Market Share: Top 5 players account for approximately xx% of the global market.

- M&A Activity: The last five years have seen an average of xx M&A deals annually.

- Regulatory Landscape: Stringent environmental regulations are driving the adoption of more efficient and environmentally friendly die casting machines.

- Substitute Products: Competition from alternative manufacturing processes limits market growth to some extent.

Aluminum Die Casting Machine Market Industry Insights & Trends

The Aluminum Die Casting Machine market is witnessing robust growth, driven by several factors. The automotive industry's increasing demand for lightweight and high-strength components is a major catalyst. The expansion of the 3C (computer, communication, consumer electronics) industry, along with growing demand from other sectors, further fuels market expansion. Technological advancements, such as the introduction of automated die casting machines and improved die-casting technologies, are enhancing production efficiency and quality, thus stimulating market growth. The rising adoption of advanced materials like aluminum alloys, coupled with evolving consumer preferences for durable and aesthetically pleasing products, supports the market's upward trajectory. The global market size was valued at xx Million in 2024 and is projected to reach xx Million by 2033.

Key Markets & Segments Leading Aluminum Die Casting Machine Market

The global Aluminum Die Casting Machine Market is experiencing robust growth, propelled by evolving industry demands and technological advancements. The automotive industry remains the cornerstone of this market, currently representing approximately XX% of the total market share. This dominance is a direct consequence of the escalating need for lightweight vehicles to enhance fuel efficiency and reduce emissions, coupled with the increasing complexity and integration of die-cast components for structural integrity and performance. Beyond automotive, the 3C industry (Computer, Communication, and Consumer Electronics) is exhibiting substantial growth potential. This surge is fueled by the ever-increasing demand for sophisticated, high-performance electronic gadgets and components that rely on the precision and quality offered by aluminum die casting.

Geographically, the Asia-Pacific region stands as the undisputed leader, commanding an estimated XX% of the global market share in 2024. This leadership is underpinned by rapid industrialization, significant investments in manufacturing infrastructure, and a burgeoning domestic and export demand from key end-user sectors.

In terms of machine types, cold chamber die casting machines continue to hold a larger market share compared to their hot chamber counterparts. This preference is attributed to their superior precision, enhanced control over the casting process, and their adaptability to a wider range of alloys, including those with higher melting points. Aluminum, owing to its exceptional lightweight yet durable properties, its excellent strength-to-weight ratio, and cost-effectiveness, remains the dominant raw material in this sector.

- By Machine Type:

- Cold Chamber Die Casting Machines: These machines dominate the market due to their inherent precision, versatility in handling various aluminum alloys, and suitability for larger casting sizes, making them ideal for demanding automotive and industrial applications.

- Hot Chamber Die Casting Machines: While generally more suited for lower melting point alloys like zinc, hot chamber machines are still preferred in certain niche applications due to their lower initial investment cost and higher cycling speeds for smaller, less complex parts.

- By Industry:

- Automotive: The primary driver, with a relentless demand for lightweight structural components, engine parts, and interior elements aimed at improving fuel efficiency and meeting stringent environmental regulations.

- 3C Industry: Experiencing rapid expansion as manufacturers seek high-quality, precisely cast aluminum enclosures, internal components, and heat sinks for advanced consumer electronics and communication devices.

- Other Industries: This segment encompasses a diverse range of applications including aerospace, medical devices, power tools, and home appliances, all contributing to steady growth through specialized requirements.

- By Raw Material:

- Aluminum: The preeminent material, valued for its ideal balance of strength, low density, corrosion resistance, and recyclability, making it the go-to choice for weight reduction initiatives.

- Magnesium: A growing niche material, offering even lighter weight than aluminum. Its adoption is steadily increasing in specialized applications where extreme weight savings are critical, though its higher cost and processing considerations remain a factor.

- Other Raw Materials: This segment includes materials like zinc and occasionally other specialized alloys, used in specific applications where their unique properties, such as high fluidity or excellent EMI shielding, are required.

Regional Dominance: As previously highlighted, the Asia-Pacific region continues to lead the Aluminum Die Casting Machine Market. This is a testament to its robust economic growth, the significant expansion of its manufacturing base, and the sustained high demand from its rapidly growing automotive and burgeoning electronics industries. The presence of major manufacturing hubs and a skilled workforce further solidifies its leading position.

Aluminum Die Casting Machine Market Product Developments

The Aluminum Die Casting Machine Market is characterized by continuous innovation, with manufacturers consistently introducing advanced technologies to meet evolving industry demands. Recent years have seen significant breakthroughs, including the development and widespread adoption of more sophisticated and precise control systems. These systems leverage advanced algorithms and sensor technology to ensure tighter tolerances, improved shot consistency, and enhanced overall casting quality. Automated operation is another key area of development, with machines increasingly equipped with integrated robotic cells for part extraction, trimming, and post-processing, leading to substantial improvements in production efficiency, reduced labor costs, and enhanced worker safety.

The integration of advanced monitoring systems, including real-time data analytics and predictive maintenance capabilities, is also a critical trend. These systems allow for continuous quality control, early detection of potential issues, and optimization of machine performance, minimizing downtime and scrap rates. These technological advancements have not only broadened the application scope of die-cast aluminum components across various industries but have also directly translated into increased market demand. Furthermore, new machine designs are prioritizing reduced energy consumption through more efficient hydraulic and electric drives, alongside improved safety mechanisms and enhanced durability, all contributing to a stronger competitive edge for manufacturers and greater value for end-users.

Challenges in the Aluminum Die Casting Machine Market Market

The Aluminum Die Casting Machine market faces several challenges, including stringent environmental regulations that impose stricter emission standards. Supply chain disruptions can lead to delays and increased costs, affecting profitability. Intense competition from existing players and the entry of new players with innovative technologies increase market pressure. Fluctuations in raw material prices also pose a significant challenge, impacting production costs and profitability margins. These factors collectively influence the market's growth trajectory and profitability of individual players.

Forces Driving Aluminum Die Casting Machine Market Growth

Several factors propel the growth of the Aluminum Die Casting Machine market. Technological advancements, such as improved automation and control systems, enhance productivity and quality. The rising demand for lightweight components across various industries, particularly in the automotive and 3C sectors, boosts market growth. Supportive government policies and incentives promoting sustainable manufacturing further stimulate market expansion. The development of advanced aluminum alloys with improved properties contributes to the broader adoption of die casting technology.

Challenges in the Aluminum Die Casting Machine Market Market

Long-term growth hinges on overcoming technological limitations in high-pressure die casting and integrating advanced monitoring and control systems. Strategic partnerships and collaborations between machine manufacturers and end-users are crucial to develop customized solutions that meet specific industrial requirements. Expanding into new emerging markets and diversifying product portfolios can further fuel long-term growth.

Emerging Opportunities in Aluminum Die Casting Machine Market

The Aluminum Die Casting Machine Market is ripe with emerging opportunities, driven by global trends towards sustainability, electrification, and advanced manufacturing. A significant area of growth lies in the development and adoption of advanced materials and sophisticated lightweighting technologies. As industries strive to reduce their environmental impact and improve performance, the demand for precisely die-cast aluminum components capable of replacing heavier traditional materials is on the rise.

The burgeoning electric vehicle (EV) sector presents a colossal opportunity. EVs require a multitude of lightweight, high-strength aluminum components for battery enclosures, structural parts, and motor housings, directly driving the demand for specialized die casting solutions. Similarly, the renewable energy sector, particularly in areas like solar panel mounting structures and wind turbine components, offers considerable potential for market expansion.

The widespread adoption of Industry 4.0 technologies, such as the Internet of Things (IoT) and Artificial Intelligence (AI), is creating new avenues for growth. These technologies enable enhanced automation, real-time data analytics for process optimization, predictive maintenance, and improved traceability, leading to more efficient and intelligent die casting operations. Beyond the traditional automotive and 3C sectors, actively exploring new applications in aerospace, medical equipment, defense, and consumer goods can unlock further substantial market growth and diversification.

Leading Players in the Aluminum Die Casting Machine Sector

- Ube Industries Ltd

- Toyo Machinery & Metal Co Ltd

- Buhler AG

- Dynacast (Form Technologies)

- LK Technology Holdings Ltd

- Italpresse Gauss

- Toshiba Machine Co Ltd

- Oskar Frech GmbH + Co KG

- IDRA Group

- Zitai Precision Machinery Co Lt

Key Milestones in Aluminum Die Casting Machine Market Industry

The Aluminum Die Casting Machine Market landscape is continually shaped by strategic partnerships, technological advancements, and market expansions. Here are some notable recent milestones:

- May 2022: GF Casting Solutions and Bocar Group announced a significant strategic collaboration aimed at expanding their joint offerings in high-pressure die casting components, enhancing their market reach and technological capabilities.

- January 2022: Jingcheng Gongke and LK Group formed a pivotal collaboration focused on advancing integrated body structural die casting technology, a crucial development for the automotive industry's shift towards unibody construction.

- December 2021: Nissei ASB Machine Co. Ltd. and Shibaura Machine Co. Ltd. established a partnership to leverage their combined expertise and technologies for penetrating and serving emerging markets more effectively.

- February 2021: Nantong Jiangzhong Photoelectricity Co. Ltd. made a strategic investment by installing an advanced Italpresse Gauss HPDC machine, underscoring its commitment to adopting cutting-edge die casting technology.

- September 2021: Hanon Systems inaugurated new, state-of-the-art facilities in Hungary, featuring modern machinery for horizontal die casting, reinforcing its production capacity and technological prowess in the automotive supply chain.

Strategic Outlook for Aluminum Die Casting Machine Market Market

The future of the Aluminum Die Casting Machine market is bright, driven by sustained growth in key industries like automotive and electronics. Strategic partnerships, technological innovation, and expansion into new geographical regions are crucial for sustained growth. Focusing on sustainability and energy efficiency will be crucial in shaping the future landscape. The market will continue to evolve with advanced technologies and materials driving efficiency and product diversification.

Aluminum Die Casting Machine Market Segmentation

-

1. Machine Type

- 1.1. Cold Chamber Die Casting Machines

- 1.2. Hot Chamber Die Casting Machines

-

2. Industry

- 2.1. Automotive

- 2.2. 3C Industry

- 2.3. Other Industries

-

3. Raw Material

- 3.1. Aluminum

- 3.2. Magnesium

- 3.3. Other Raw Materials

Aluminum Die Casting Machine Market Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Rest of North America

-

2. Europe

- 2.1. Germany

- 2.2. United Kingdom

- 2.3. France

- 2.4. Italy

- 2.5. Rest of Europe

-

3. Asia Pacific

- 3.1. China

- 3.2. India

- 3.3. South Korea

- 3.4. Japan

- 3.5. Rest of Asia Pacific

-

4. Rest of the World

- 4.1. South America

- 4.2. Middle East and Africa

Aluminum Die Casting Machine Market Regional Market Share

Geographic Coverage of Aluminum Die Casting Machine Market

Aluminum Die Casting Machine Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 6.16% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Rising Recreational and Motorsports Activities is Expected to Drive the Market; Others

- 3.3. Market Restrains

- 3.3.1. High Value and Maintenance Cost Offered to Restrain the Market Growth; Others

- 3.4. Market Trends

- 3.4.1. Growing Adoption of Aluminum in Die Casting Machinery to Enhance Demand in the Market

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Aluminum Die Casting Machine Market Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Machine Type

- 5.1.1. Cold Chamber Die Casting Machines

- 5.1.2. Hot Chamber Die Casting Machines

- 5.2. Market Analysis, Insights and Forecast - by Industry

- 5.2.1. Automotive

- 5.2.2. 3C Industry

- 5.2.3. Other Industries

- 5.3. Market Analysis, Insights and Forecast - by Raw Material

- 5.3.1. Aluminum

- 5.3.2. Magnesium

- 5.3.3. Other Raw Materials

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. North America

- 5.4.2. Europe

- 5.4.3. Asia Pacific

- 5.4.4. Rest of the World

- 5.1. Market Analysis, Insights and Forecast - by Machine Type

- 6. North America Aluminum Die Casting Machine Market Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Machine Type

- 6.1.1. Cold Chamber Die Casting Machines

- 6.1.2. Hot Chamber Die Casting Machines

- 6.2. Market Analysis, Insights and Forecast - by Industry

- 6.2.1. Automotive

- 6.2.2. 3C Industry

- 6.2.3. Other Industries

- 6.3. Market Analysis, Insights and Forecast - by Raw Material

- 6.3.1. Aluminum

- 6.3.2. Magnesium

- 6.3.3. Other Raw Materials

- 6.1. Market Analysis, Insights and Forecast - by Machine Type

- 7. Europe Aluminum Die Casting Machine Market Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Machine Type

- 7.1.1. Cold Chamber Die Casting Machines

- 7.1.2. Hot Chamber Die Casting Machines

- 7.2. Market Analysis, Insights and Forecast - by Industry

- 7.2.1. Automotive

- 7.2.2. 3C Industry

- 7.2.3. Other Industries

- 7.3. Market Analysis, Insights and Forecast - by Raw Material

- 7.3.1. Aluminum

- 7.3.2. Magnesium

- 7.3.3. Other Raw Materials

- 7.1. Market Analysis, Insights and Forecast - by Machine Type

- 8. Asia Pacific Aluminum Die Casting Machine Market Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Machine Type

- 8.1.1. Cold Chamber Die Casting Machines

- 8.1.2. Hot Chamber Die Casting Machines

- 8.2. Market Analysis, Insights and Forecast - by Industry

- 8.2.1. Automotive

- 8.2.2. 3C Industry

- 8.2.3. Other Industries

- 8.3. Market Analysis, Insights and Forecast - by Raw Material

- 8.3.1. Aluminum

- 8.3.2. Magnesium

- 8.3.3. Other Raw Materials

- 8.1. Market Analysis, Insights and Forecast - by Machine Type

- 9. Rest of the World Aluminum Die Casting Machine Market Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Machine Type

- 9.1.1. Cold Chamber Die Casting Machines

- 9.1.2. Hot Chamber Die Casting Machines

- 9.2. Market Analysis, Insights and Forecast - by Industry

- 9.2.1. Automotive

- 9.2.2. 3C Industry

- 9.2.3. Other Industries

- 9.3. Market Analysis, Insights and Forecast - by Raw Material

- 9.3.1. Aluminum

- 9.3.2. Magnesium

- 9.3.3. Other Raw Materials

- 9.1. Market Analysis, Insights and Forecast - by Machine Type

- 10. Competitive Analysis

- 10.1. Global Market Share Analysis 2025

- 10.2. Company Profiles

- 10.2.1 Ube Industries Ltd

- 10.2.1.1. Overview

- 10.2.1.2. Products

- 10.2.1.3. SWOT Analysis

- 10.2.1.4. Recent Developments

- 10.2.1.5. Financials (Based on Availability)

- 10.2.2 Toyo Machinery & Metal Co Ltd

- 10.2.2.1. Overview

- 10.2.2.2. Products

- 10.2.2.3. SWOT Analysis

- 10.2.2.4. Recent Developments

- 10.2.2.5. Financials (Based on Availability)

- 10.2.3 Buhler AG

- 10.2.3.1. Overview

- 10.2.3.2. Products

- 10.2.3.3. SWOT Analysis

- 10.2.3.4. Recent Developments

- 10.2.3.5. Financials (Based on Availability)

- 10.2.4 Dynacast (Form Technologies)

- 10.2.4.1. Overview

- 10.2.4.2. Products

- 10.2.4.3. SWOT Analysis

- 10.2.4.4. Recent Developments

- 10.2.4.5. Financials (Based on Availability)

- 10.2.5 LK Technology Holdings Ltd

- 10.2.5.1. Overview

- 10.2.5.2. Products

- 10.2.5.3. SWOT Analysis

- 10.2.5.4. Recent Developments

- 10.2.5.5. Financials (Based on Availability)

- 10.2.6 Italpresse Gauss

- 10.2.6.1. Overview

- 10.2.6.2. Products

- 10.2.6.3. SWOT Analysis

- 10.2.6.4. Recent Developments

- 10.2.6.5. Financials (Based on Availability)

- 10.2.7 Toshiba Machine Co Ltd

- 10.2.7.1. Overview

- 10.2.7.2. Products

- 10.2.7.3. SWOT Analysis

- 10.2.7.4. Recent Developments

- 10.2.7.5. Financials (Based on Availability)

- 10.2.8 Oskar Frech GmbH + Co KG

- 10.2.8.1. Overview

- 10.2.8.2. Products

- 10.2.8.3. SWOT Analysis

- 10.2.8.4. Recent Developments

- 10.2.8.5. Financials (Based on Availability)

- 10.2.9 IDRA Group

- 10.2.9.1. Overview

- 10.2.9.2. Products

- 10.2.9.3. SWOT Analysis

- 10.2.9.4. Recent Developments

- 10.2.9.5. Financials (Based on Availability)

- 10.2.10 Zitai Precision Machinery Co Lt

- 10.2.10.1. Overview

- 10.2.10.2. Products

- 10.2.10.3. SWOT Analysis

- 10.2.10.4. Recent Developments

- 10.2.10.5. Financials (Based on Availability)

- 10.2.1 Ube Industries Ltd

List of Figures

- Figure 1: Global Aluminum Die Casting Machine Market Revenue Breakdown (billion, %) by Region 2025 & 2033

- Figure 2: North America Aluminum Die Casting Machine Market Revenue (billion), by Machine Type 2025 & 2033

- Figure 3: North America Aluminum Die Casting Machine Market Revenue Share (%), by Machine Type 2025 & 2033

- Figure 4: North America Aluminum Die Casting Machine Market Revenue (billion), by Industry 2025 & 2033

- Figure 5: North America Aluminum Die Casting Machine Market Revenue Share (%), by Industry 2025 & 2033

- Figure 6: North America Aluminum Die Casting Machine Market Revenue (billion), by Raw Material 2025 & 2033

- Figure 7: North America Aluminum Die Casting Machine Market Revenue Share (%), by Raw Material 2025 & 2033

- Figure 8: North America Aluminum Die Casting Machine Market Revenue (billion), by Country 2025 & 2033

- Figure 9: North America Aluminum Die Casting Machine Market Revenue Share (%), by Country 2025 & 2033

- Figure 10: Europe Aluminum Die Casting Machine Market Revenue (billion), by Machine Type 2025 & 2033

- Figure 11: Europe Aluminum Die Casting Machine Market Revenue Share (%), by Machine Type 2025 & 2033

- Figure 12: Europe Aluminum Die Casting Machine Market Revenue (billion), by Industry 2025 & 2033

- Figure 13: Europe Aluminum Die Casting Machine Market Revenue Share (%), by Industry 2025 & 2033

- Figure 14: Europe Aluminum Die Casting Machine Market Revenue (billion), by Raw Material 2025 & 2033

- Figure 15: Europe Aluminum Die Casting Machine Market Revenue Share (%), by Raw Material 2025 & 2033

- Figure 16: Europe Aluminum Die Casting Machine Market Revenue (billion), by Country 2025 & 2033

- Figure 17: Europe Aluminum Die Casting Machine Market Revenue Share (%), by Country 2025 & 2033

- Figure 18: Asia Pacific Aluminum Die Casting Machine Market Revenue (billion), by Machine Type 2025 & 2033

- Figure 19: Asia Pacific Aluminum Die Casting Machine Market Revenue Share (%), by Machine Type 2025 & 2033

- Figure 20: Asia Pacific Aluminum Die Casting Machine Market Revenue (billion), by Industry 2025 & 2033

- Figure 21: Asia Pacific Aluminum Die Casting Machine Market Revenue Share (%), by Industry 2025 & 2033

- Figure 22: Asia Pacific Aluminum Die Casting Machine Market Revenue (billion), by Raw Material 2025 & 2033

- Figure 23: Asia Pacific Aluminum Die Casting Machine Market Revenue Share (%), by Raw Material 2025 & 2033

- Figure 24: Asia Pacific Aluminum Die Casting Machine Market Revenue (billion), by Country 2025 & 2033

- Figure 25: Asia Pacific Aluminum Die Casting Machine Market Revenue Share (%), by Country 2025 & 2033

- Figure 26: Rest of the World Aluminum Die Casting Machine Market Revenue (billion), by Machine Type 2025 & 2033

- Figure 27: Rest of the World Aluminum Die Casting Machine Market Revenue Share (%), by Machine Type 2025 & 2033

- Figure 28: Rest of the World Aluminum Die Casting Machine Market Revenue (billion), by Industry 2025 & 2033

- Figure 29: Rest of the World Aluminum Die Casting Machine Market Revenue Share (%), by Industry 2025 & 2033

- Figure 30: Rest of the World Aluminum Die Casting Machine Market Revenue (billion), by Raw Material 2025 & 2033

- Figure 31: Rest of the World Aluminum Die Casting Machine Market Revenue Share (%), by Raw Material 2025 & 2033

- Figure 32: Rest of the World Aluminum Die Casting Machine Market Revenue (billion), by Country 2025 & 2033

- Figure 33: Rest of the World Aluminum Die Casting Machine Market Revenue Share (%), by Country 2025 & 2033

List of Tables

- Table 1: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Machine Type 2020 & 2033

- Table 2: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Industry 2020 & 2033

- Table 3: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Raw Material 2020 & 2033

- Table 4: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Region 2020 & 2033

- Table 5: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Machine Type 2020 & 2033

- Table 6: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Industry 2020 & 2033

- Table 7: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Raw Material 2020 & 2033

- Table 8: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Country 2020 & 2033

- Table 9: United States Aluminum Die Casting Machine Market Revenue (billion) Forecast, by Application 2020 & 2033

- Table 10: Canada Aluminum Die Casting Machine Market Revenue (billion) Forecast, by Application 2020 & 2033

- Table 11: Rest of North America Aluminum Die Casting Machine Market Revenue (billion) Forecast, by Application 2020 & 2033

- Table 12: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Machine Type 2020 & 2033

- Table 13: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Industry 2020 & 2033

- Table 14: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Raw Material 2020 & 2033

- Table 15: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Country 2020 & 2033

- Table 16: Germany Aluminum Die Casting Machine Market Revenue (billion) Forecast, by Application 2020 & 2033

- Table 17: United Kingdom Aluminum Die Casting Machine Market Revenue (billion) Forecast, by Application 2020 & 2033

- Table 18: France Aluminum Die Casting Machine Market Revenue (billion) Forecast, by Application 2020 & 2033

- Table 19: Italy Aluminum Die Casting Machine Market Revenue (billion) Forecast, by Application 2020 & 2033

- Table 20: Rest of Europe Aluminum Die Casting Machine Market Revenue (billion) Forecast, by Application 2020 & 2033

- Table 21: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Machine Type 2020 & 2033

- Table 22: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Industry 2020 & 2033

- Table 23: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Raw Material 2020 & 2033

- Table 24: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Country 2020 & 2033

- Table 25: China Aluminum Die Casting Machine Market Revenue (billion) Forecast, by Application 2020 & 2033

- Table 26: India Aluminum Die Casting Machine Market Revenue (billion) Forecast, by Application 2020 & 2033

- Table 27: South Korea Aluminum Die Casting Machine Market Revenue (billion) Forecast, by Application 2020 & 2033

- Table 28: Japan Aluminum Die Casting Machine Market Revenue (billion) Forecast, by Application 2020 & 2033

- Table 29: Rest of Asia Pacific Aluminum Die Casting Machine Market Revenue (billion) Forecast, by Application 2020 & 2033

- Table 30: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Machine Type 2020 & 2033

- Table 31: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Industry 2020 & 2033

- Table 32: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Raw Material 2020 & 2033

- Table 33: Global Aluminum Die Casting Machine Market Revenue billion Forecast, by Country 2020 & 2033

- Table 34: South America Aluminum Die Casting Machine Market Revenue (billion) Forecast, by Application 2020 & 2033

- Table 35: Middle East and Africa Aluminum Die Casting Machine Market Revenue (billion) Forecast, by Application 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Aluminum Die Casting Machine Market?

The projected CAGR is approximately 6.16%.

2. Which companies are prominent players in the Aluminum Die Casting Machine Market?

Key companies in the market include Ube Industries Ltd, Toyo Machinery & Metal Co Ltd, Buhler AG, Dynacast (Form Technologies), LK Technology Holdings Ltd, Italpresse Gauss, Toshiba Machine Co Ltd, Oskar Frech GmbH + Co KG, IDRA Group, Zitai Precision Machinery Co Lt.

3. What are the main segments of the Aluminum Die Casting Machine Market?

The market segments include Machine Type, Industry, Raw Material.

4. Can you provide details about the market size?

The market size is estimated to be USD 3.83 billion as of 2022.

5. What are some drivers contributing to market growth?

Rising Recreational and Motorsports Activities is Expected to Drive the Market; Others.

6. What are the notable trends driving market growth?

Growing Adoption of Aluminum in Die Casting Machinery to Enhance Demand in the Market.

7. Are there any restraints impacting market growth?

High Value and Maintenance Cost Offered to Restrain the Market Growth; Others.

8. Can you provide examples of recent developments in the market?

In May 2022, GF Casting Solutions, a division of GF, Schaffhausen (Switzerland), and the leading light-metal castings and assemblies solutions provider Bocar Group, Mexico City (Mexico), signed an agreement to offer a specialized range of products and services worldwide. The objective of the collaboration is to bring higher value to the customers by combining the capabilities of two leading players in the market for high-pressure die casting components.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in billion.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Aluminum Die Casting Machine Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Aluminum Die Casting Machine Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Aluminum Die Casting Machine Market?

To stay informed about further developments, trends, and reports in the Aluminum Die Casting Machine Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

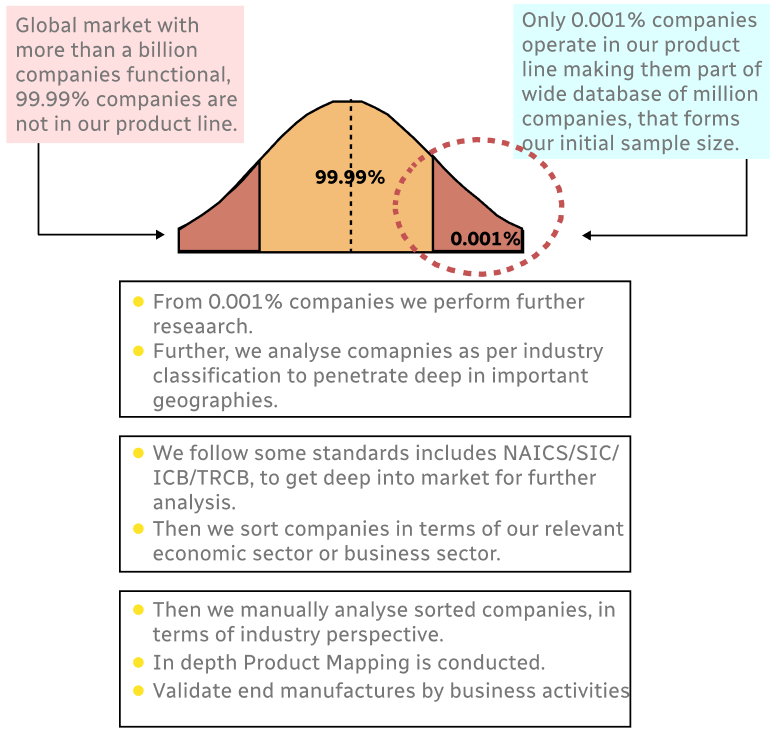

Step 1 - Identification of Relevant Samples Size from Population Database

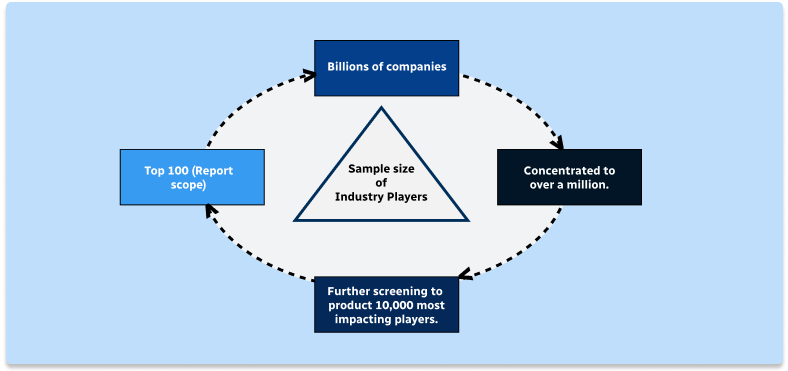

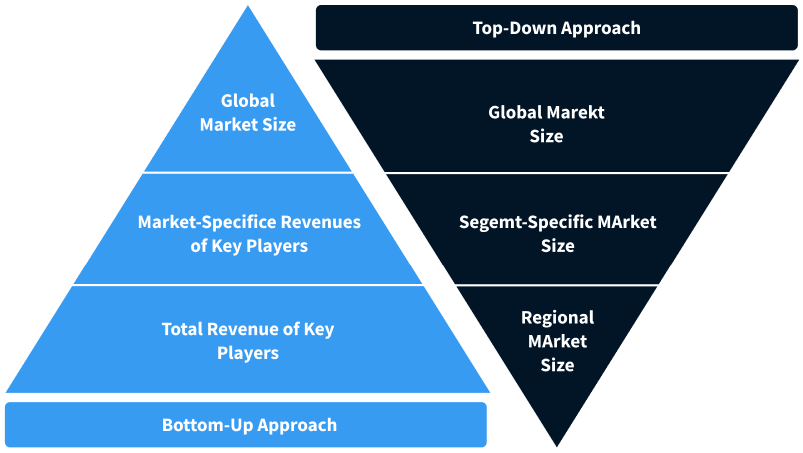

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

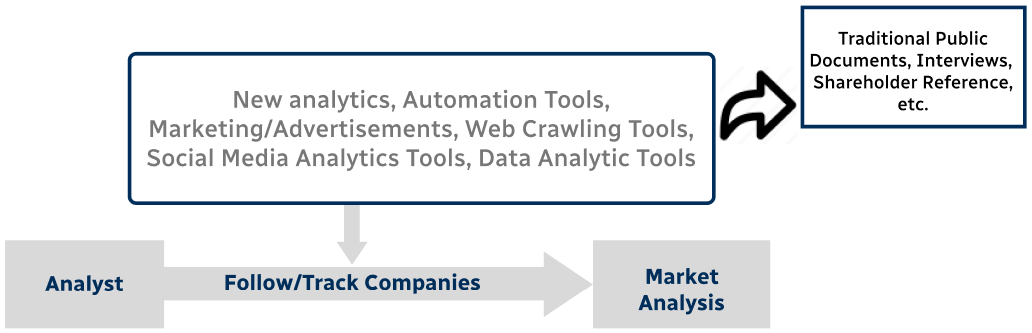

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence