Key Insights

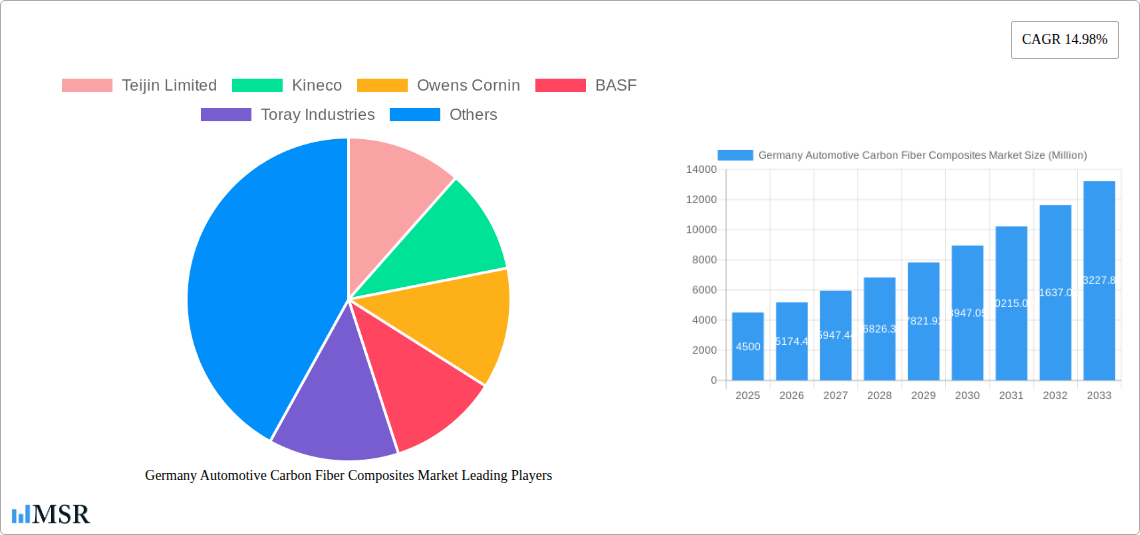

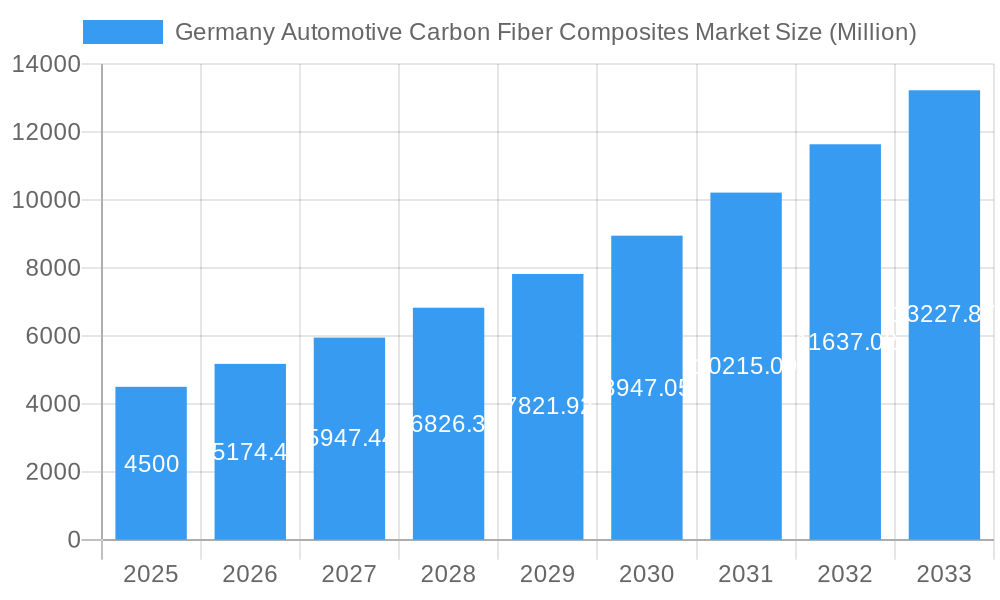

The German automotive carbon fiber composites market is poised for robust expansion, driven by increasing demand for lightweight and high-performance materials in vehicles. Valued at an estimated $4.5 billion in 2025, the market is projected to witness a remarkable Compound Annual Growth Rate (CAGR) of 14.98% throughout the forecast period of 2025-2033. This significant growth is fueled by key drivers such as stringent automotive emission regulations, the escalating need for improved fuel efficiency, and the growing consumer preference for vehicles with enhanced performance and safety features. Carbon fiber composites offer a compelling solution by significantly reducing vehicle weight, leading to lower fuel consumption and reduced CO2 emissions, thus aligning with global sustainability objectives. Furthermore, advancements in manufacturing technologies like Resin Transfer Molding (RTM) and Vacuum Infusion Processing are making carbon fiber composites more cost-effective and scalable for mass production, further propelling their adoption.

Germany Automotive Carbon Fiber Composites Market Market Size (In Billion)

The market's dynamism is further shaped by emerging trends and distinct segments. The increasing integration of carbon fiber composites in structural assemblies and powertrain components signifies a shift towards their use in critical vehicle parts where strength and weight reduction are paramount. While thermoset polymers currently dominate, the growing interest in thermoplastic composites, offering recyclability and faster processing times, presents a significant growth avenue. Despite the promising outlook, certain restraints, such as the relatively high initial cost of materials and manufacturing processes compared to traditional materials like steel and aluminum, and the need for specialized infrastructure for processing and repair, could temper the pace of adoption. However, ongoing research and development efforts focused on cost reduction and improved manufacturing efficiency are actively addressing these challenges, positioning Germany as a key innovation hub for automotive carbon fiber composite solutions.

Germany Automotive Carbon Fiber Composites Market Company Market Share

Germany Automotive Carbon Fiber Composites Market: Unlocking Lightweighting and Performance in a Shifting Auto Landscape

This comprehensive report offers an in-depth analysis of the Germany automotive carbon fiber composites market, exploring its dynamic growth, key trends, and future potential. Dive into the insights driving the adoption of advanced materials in the German automotive sector, from structural assemblies and powertrain components to interior and exterior applications. This study provides critical market intelligence for stakeholders looking to capitalize on the burgeoning demand for lightweight, high-performance solutions in one of the world's leading automotive hubs.

Study Period: 2019–2033 | Base Year: 2025 | Estimated Year: 2025 | Forecast Period: 2025–2033 | Historical Period: 2019–2024

Germany Automotive Carbon Fiber Composites Market Market Concentration & Dynamics

The Germany automotive carbon fiber composites market exhibits a moderate concentration, characterized by the presence of global giants and specialized domestic players. Innovation ecosystems are thriving, fueled by significant R&D investments from leading companies aiming to develop advanced carbon fiber reinforced polymer (CFRP) solutions for automotive applications. Regulatory frameworks, particularly those focused on vehicle emissions and safety standards, are indirectly fostering the adoption of lightweight composites. The market's dynamics are shaped by the constant pressure to reduce vehicle weight for improved fuel efficiency and lower emissions, directly impacting lightweight automotive materials.

Substitute products, primarily advanced high-strength steels and aluminum alloys, continue to pose a challenge. However, the superior strength-to-weight ratio of carbon fiber composites positions them favorably for specific performance-critical applications. End-user trends are clearly leaning towards electrification and autonomous driving, both of which demand lighter vehicle architectures to maximize range and optimize sensor integration. Merger and acquisition (M&A) activities, while not pervasive, are strategic, with larger players acquiring niche technology providers to enhance their composite capabilities. Market share is fragmented but consolidating, with key players investing heavily in expanding production capacities for automotive grade carbon fiber and thermoset polymer composites. The growing emphasis on sustainability is also influencing material choices and manufacturing processes.

Germany Automotive Carbon Fiber Composites Market Industry Insights & Trends

The Germany automotive carbon fiber composites market is poised for robust growth, driven by an insatiable demand for enhanced vehicle performance, fuel efficiency, and emissions reduction. The market size is projected to reach approximately $7,500 Million by 2025, with a compelling Compound Annual Growth Rate (CAGR) of XX% during the forecast period of 2025–2033. This surge is underpinned by several key factors. Technological disruptions are continuously refining carbon fiber manufacturing processes, making them more cost-effective and scalable for mass production. Innovations in thermoplastic composites are gaining traction, offering advantages in terms of faster cycle times and recyclability compared to traditional thermosets.

Evolving consumer behaviors, particularly the increasing preference for premium vehicles and sports cars, where performance and aesthetics are paramount, directly benefit the adoption of high-performance automotive materials. Furthermore, the stringent EU emissions regulations and the German government's push for electromobility are significant market growth drivers. Lightweighting is no longer a niche consideration but a fundamental requirement for automakers to meet fleet-wide CO2 targets, making automotive structural composites indispensable. The integration of carbon fiber parts into electric vehicles (EVs) is crucial for battery weight compensation and extending driving range. The development of advanced resin transfer molding (RTM) and vacuum infusion processing (VIP) techniques are enabling the production of complex geometries with improved structural integrity, further propelling the market. The rising adoption of advanced driver-assistance systems (ADAS) and autonomous driving technologies also necessitates lighter vehicle frames to accommodate additional sensors and electronic components.

Key Markets & Segments Leading Germany Automotive Carbon Fiber Composites Market

The Germany automotive carbon fiber composites market is primarily dominated by the Structural Assembly application segment. This dominance is fueled by the critical need for lightweighting in chassis, body-in-white components, and battery enclosures for electric vehicles. The inherent high tensile strength and stiffness of carbon fiber make it the material of choice for enhancing structural integrity while significantly reducing overall vehicle weight.

Production Type Dominance:

- Resin Transfer Molding (RTM) and Vacuum Infusion Processing (VIP) are leading production types due to their ability to produce complex, high-quality composite parts with excellent surface finish and controlled fiber orientation, crucial for automotive structural applications.

- Hand Layup continues to hold a significant share, particularly for prototyping and low-volume production, offering flexibility.

- Injection Molding and Compression Molding are gaining traction for thermoplastic composites, offering faster cycle times and automation potential.

Material Type Dominance:

- Carbon Fiber is the undisputed leader, underpinning the "carbon fiber composites" market. Its exceptional mechanical properties are irreplaceable for demanding automotive applications.

- Thermoset Polymer dominates due to its proven performance, durability, and established manufacturing processes.

- Thermoplastic Polymer is an emerging segment with substantial growth potential due to its recyclability and faster processing capabilities.

- Glass Fiber is still prevalent, often used in conjunction with carbon fiber for hybrid composites or in less performance-critical applications, contributing to the overall automotive composite materials market.

Application Dominance:

- Structural Assembly leads due to the direct impact on vehicle performance, safety, and efficiency. This includes applications like chassis components, A-pillars, B-pillars, roof structures, and battery casings.

- Powertrain Component applications are growing, especially in high-performance vehicles and EV drivetrains where weight reduction is critical.

- Exterior applications like hoods, trunk lids, and spoilers are increasingly utilizing composites for both weight savings and aesthetic appeal.

- Interior applications, such as dashboards and door panels, are seeing greater adoption for premium finishes and weight reduction.

Germany Automotive Carbon Fiber Composites Market Product Developments

Recent product developments in the Germany automotive carbon fiber composites market are centered on enhancing material properties, improving manufacturing efficiency, and expanding application ranges. Innovations include the development of novel resin systems for thermoset composites that offer faster curing times and improved impact resistance. Research into advanced thermoplastic composites is yielding materials with enhanced recyclability and suitability for automated manufacturing processes like injection molding. Furthermore, the integration of carbon fiber with other advanced materials to create hybrid composites is a significant trend, allowing for tailored performance characteristics and cost optimization. These developments are directly addressing the industry's need for lighter, stronger, and more sustainable automotive solutions.

Challenges in the Germany Automotive Carbon Fiber Composites Market Market

Despite significant growth, the Germany automotive carbon fiber composites market faces several challenges. The high cost of raw materials, particularly carbon fiber, remains a primary barrier to widespread adoption, especially in mass-market vehicles. Manufacturing complexity and longer production cycle times compared to traditional metal stamping also contribute to higher part costs. Regulatory hurdles related to end-of-life recycling and disposal of composite materials are being addressed but require continued innovation and standardization. Supply chain vulnerabilities for critical raw materials can also pose risks, and competition from advanced aluminum and high-strength steel alloys, which are becoming increasingly lightweight and cost-effective, presents an ongoing challenge.

Forces Driving Germany Automotive Carbon Fiber Composites Market Growth

The Germany automotive carbon fiber composites market is propelled by powerful growth drivers. Stringent European Union emissions regulations are forcing automakers to significantly reduce vehicle weight, making lightweight automotive materials like carbon fiber composites essential for achieving fleet-wide CO2 targets. The accelerating shift towards electric vehicles (EVs) further amplifies this need, as lightweighting helps offset the battery weight and extend driving range. Technological advancements in composite manufacturing processes, such as RTM and VIP, are improving efficiency and reducing costs, making composites more accessible. Growing consumer demand for performance and premium features, where lightweighting translates to better handling and acceleration, also contributes to market expansion. Government incentives for EVs and advanced manufacturing further bolster growth.

Challenges in the Germany Automotive Carbon Fiber Composites Market Market

Long-term growth catalysts for the Germany automotive carbon fiber composites market lie in continued innovation and strategic market expansion. The development of advanced thermoplastic composites that offer faster processing and recyclability will be critical for mass adoption. Partnerships between material manufacturers, automotive OEMs, and research institutions are fostering a collaborative environment for developing next-generation composite solutions. Expanding applications beyond structural components into areas like energy storage systems and advanced interior elements will unlock new revenue streams. The ongoing quest for sustainable manufacturing practices, including the use of bio-based resins and enhanced recycling methods, will also be a significant long-term driver, aligning with the industry's sustainability goals and consumer preferences for eco-friendly vehicles.

Emerging Opportunities in Germany Automotive Carbon Fiber Composites Market

Emerging opportunities in the Germany automotive carbon fiber composites market are diverse and promising. The burgeoning EV market presents a significant opportunity, particularly in the development of lightweight battery enclosures, chassis components, and structural elements that enhance vehicle range and performance. The increasing demand for advanced driver-assistance systems (ADAS) and autonomous driving technology creates a need for lightweight structures to house sensors and electronic components. The trend towards modular vehicle architectures and customizable interior designs also opens avenues for the application of composite materials. Furthermore, advancements in additive manufacturing (3D printing) of composites offer possibilities for highly complex, customized parts and rapid prototyping, catering to niche performance applications and specialized vehicle segments.

Leading Players in the Germany Automotive Carbon Fiber Composites Market Sector

- Teijin Limited

- Kineco

- Owens Corning

- BASF

- Toray Industries

- Cytec Industries

- Gurit

- 3B-Fiberglass

- Johns Manville

- Base Group

- Nippon Sheet Glass Co Ltd

- Jushi Group Co Ltd

- SGL Group

Key Milestones in Germany Automotive Carbon Fiber Composites Market Industry

- April 2023: SGL Carbon announced a significant investment of EURO 100 million in a new plant in Germany dedicated to producing carbon fiber composites for the automotive industry, signaling strong confidence in market growth.

- May 2023: BASF unveiled a new generation of glass fiber composite, offering superior lightness and strength compared to traditional alternatives, with anticipated widespread use in automotive body panels and engine components.

Strategic Outlook for Germany Automotive Carbon Fiber Composites Market Market

The strategic outlook for the Germany automotive carbon fiber composites market is exceptionally bright, driven by the imperative for lightweighting in the automotive sector. Future growth will be accelerated by continued advancements in thermoplastic composites, enabling higher production volumes and improved recyclability, thereby addressing cost and sustainability concerns. Strategic collaborations between carbon fiber producers, resin manufacturers, and automotive OEMs will be crucial for developing integrated solutions and streamlining the supply chain. The expansion of composite applications into critical areas of electric vehicles, such as battery structures and lightweight chassis, will be a key growth accelerator. Furthermore, the increasing focus on digitalization and automation in manufacturing processes will enhance the cost-effectiveness and scalability of composite component production, ensuring sustained market expansion.

Germany Automotive Carbon Fiber Composites Market Segmentation

-

1. Production Type

- 1.1. Hand Layup

- 1.2. Resin Transfer Molding

- 1.3. Vacuum Infusion Processing

- 1.4. Injection Molding

- 1.5. Compression Molding

-

2. Material Type

- 2.1. Thermoset Polymer

- 2.2. Thermoplastic Polymer

- 2.3. Carbon Fiber

- 2.4. Glass Fiber

- 2.5. Other Material Types

-

3. Application

- 3.1. Structural Assembly

- 3.2. Power train Component

- 3.3. Interior

- 3.4. Exterior

- 3.5. Other Applications

Germany Automotive Carbon Fiber Composites Market Segmentation By Geography

- 1. Germany

Germany Automotive Carbon Fiber Composites Market Regional Market Share

Geographic Coverage of Germany Automotive Carbon Fiber Composites Market

Germany Automotive Carbon Fiber Composites Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 14.98% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Increased Focus on Fuel Efficiency; Advances in Manufacturing Technology

- 3.3. Market Restrains

- 3.3.1. High-Cost of Automotive Composites

- 3.4. Market Trends

- 3.4.1. Increasing Application of Lightweight Materials

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Germany Automotive Carbon Fiber Composites Market Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Production Type

- 5.1.1. Hand Layup

- 5.1.2. Resin Transfer Molding

- 5.1.3. Vacuum Infusion Processing

- 5.1.4. Injection Molding

- 5.1.5. Compression Molding

- 5.2. Market Analysis, Insights and Forecast - by Material Type

- 5.2.1. Thermoset Polymer

- 5.2.2. Thermoplastic Polymer

- 5.2.3. Carbon Fiber

- 5.2.4. Glass Fiber

- 5.2.5. Other Material Types

- 5.3. Market Analysis, Insights and Forecast - by Application

- 5.3.1. Structural Assembly

- 5.3.2. Power train Component

- 5.3.3. Interior

- 5.3.4. Exterior

- 5.3.5. Other Applications

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. Germany

- 5.1. Market Analysis, Insights and Forecast - by Production Type

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 Teijin Limited

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Kineco

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 Owens Cornin

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 BASF

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 Toray Industries

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Cytec Industries

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 Gurit

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 3B-Fiberglass

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 Johns Manville

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 Base Group

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.11 Nipposn Sheet Glass Co Ltd

- 6.2.11.1. Overview

- 6.2.11.2. Products

- 6.2.11.3. SWOT Analysis

- 6.2.11.4. Recent Developments

- 6.2.11.5. Financials (Based on Availability)

- 6.2.12 Jushi Group Co Ltd

- 6.2.12.1. Overview

- 6.2.12.2. Products

- 6.2.12.3. SWOT Analysis

- 6.2.12.4. Recent Developments

- 6.2.12.5. Financials (Based on Availability)

- 6.2.13 SGL Group

- 6.2.13.1. Overview

- 6.2.13.2. Products

- 6.2.13.3. SWOT Analysis

- 6.2.13.4. Recent Developments

- 6.2.13.5. Financials (Based on Availability)

- 6.2.1 Teijin Limited

List of Figures

- Figure 1: Germany Automotive Carbon Fiber Composites Market Revenue Breakdown (Million, %) by Product 2025 & 2033

- Figure 2: Germany Automotive Carbon Fiber Composites Market Share (%) by Company 2025

List of Tables

- Table 1: Germany Automotive Carbon Fiber Composites Market Revenue Million Forecast, by Production Type 2020 & 2033

- Table 2: Germany Automotive Carbon Fiber Composites Market Revenue Million Forecast, by Material Type 2020 & 2033

- Table 3: Germany Automotive Carbon Fiber Composites Market Revenue Million Forecast, by Application 2020 & 2033

- Table 4: Germany Automotive Carbon Fiber Composites Market Revenue Million Forecast, by Region 2020 & 2033

- Table 5: Germany Automotive Carbon Fiber Composites Market Revenue Million Forecast, by Production Type 2020 & 2033

- Table 6: Germany Automotive Carbon Fiber Composites Market Revenue Million Forecast, by Material Type 2020 & 2033

- Table 7: Germany Automotive Carbon Fiber Composites Market Revenue Million Forecast, by Application 2020 & 2033

- Table 8: Germany Automotive Carbon Fiber Composites Market Revenue Million Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Germany Automotive Carbon Fiber Composites Market?

The projected CAGR is approximately 14.98%.

2. Which companies are prominent players in the Germany Automotive Carbon Fiber Composites Market?

Key companies in the market include Teijin Limited, Kineco, Owens Cornin, BASF, Toray Industries, Cytec Industries, Gurit, 3B-Fiberglass, Johns Manville, Base Group, Nipposn Sheet Glass Co Ltd, Jushi Group Co Ltd, SGL Group.

3. What are the main segments of the Germany Automotive Carbon Fiber Composites Market?

The market segments include Production Type, Material Type, Application.

4. Can you provide details about the market size?

The market size is estimated to be USD 4.5 Million as of 2022.

5. What are some drivers contributing to market growth?

Increased Focus on Fuel Efficiency; Advances in Manufacturing Technology.

6. What are the notable trends driving market growth?

Increasing Application of Lightweight Materials.

7. Are there any restraints impacting market growth?

High-Cost of Automotive Composites.

8. Can you provide examples of recent developments in the market?

April 2023: SGL Carbon announced that it would be investing EURO 100 million in a new plant in Germany to produce carbon fiber composites for the automotive industry. This investment is a sign of the growing demand for automotive composites in the Germany market.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Germany Automotive Carbon Fiber Composites Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Germany Automotive Carbon Fiber Composites Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Germany Automotive Carbon Fiber Composites Market?

To stay informed about further developments, trends, and reports in the Germany Automotive Carbon Fiber Composites Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

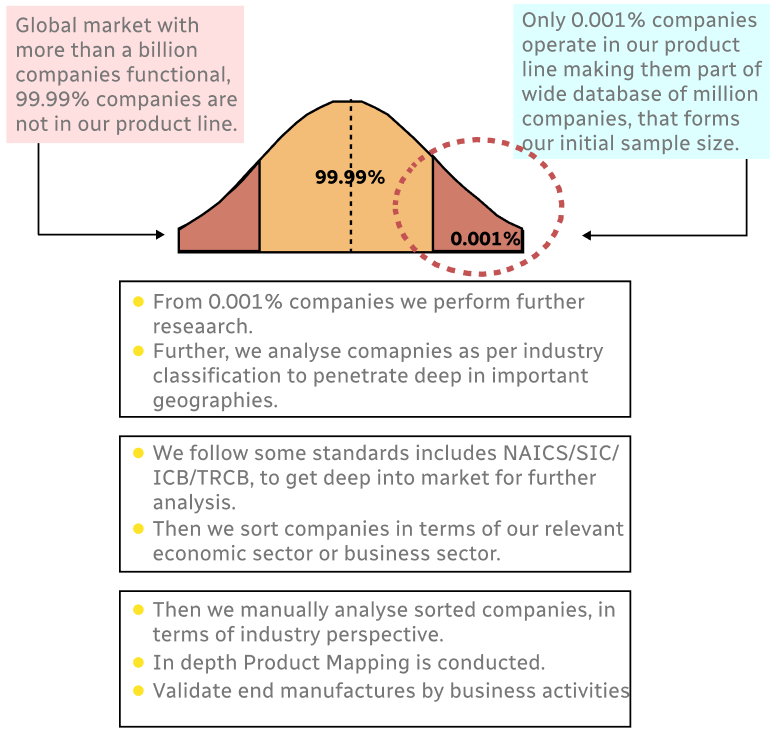

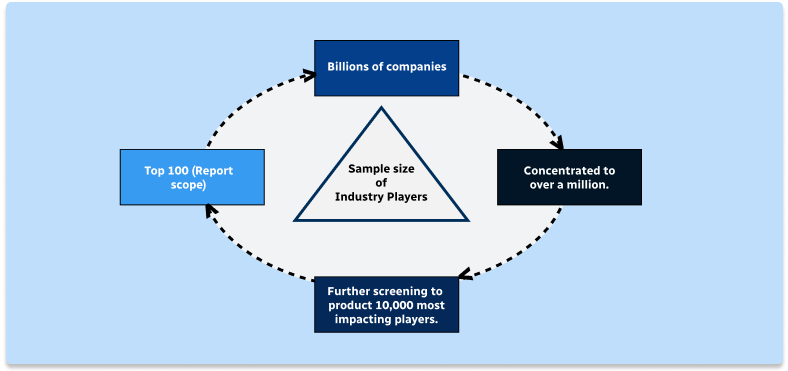

Step 1 - Identification of Relevant Samples Size from Population Database

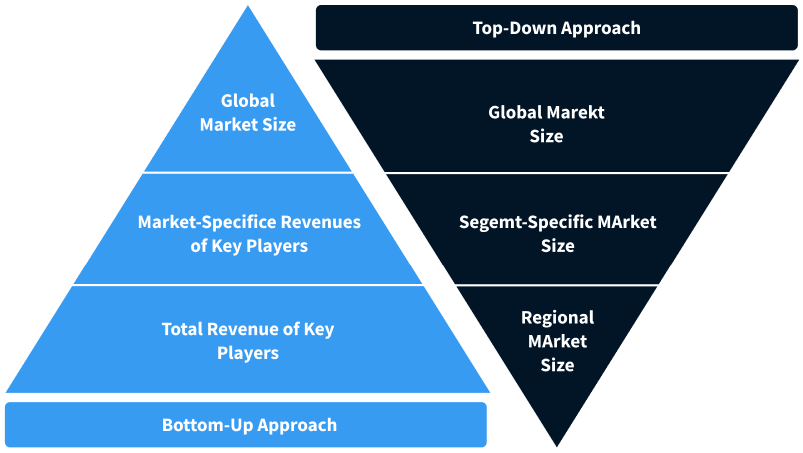

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

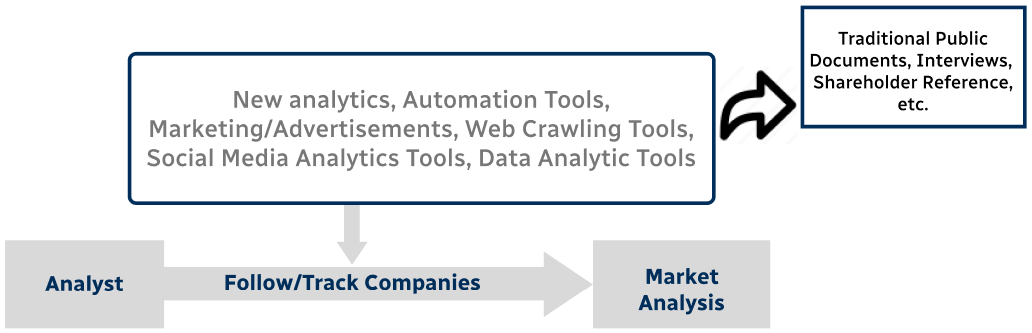

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence