Key Insights

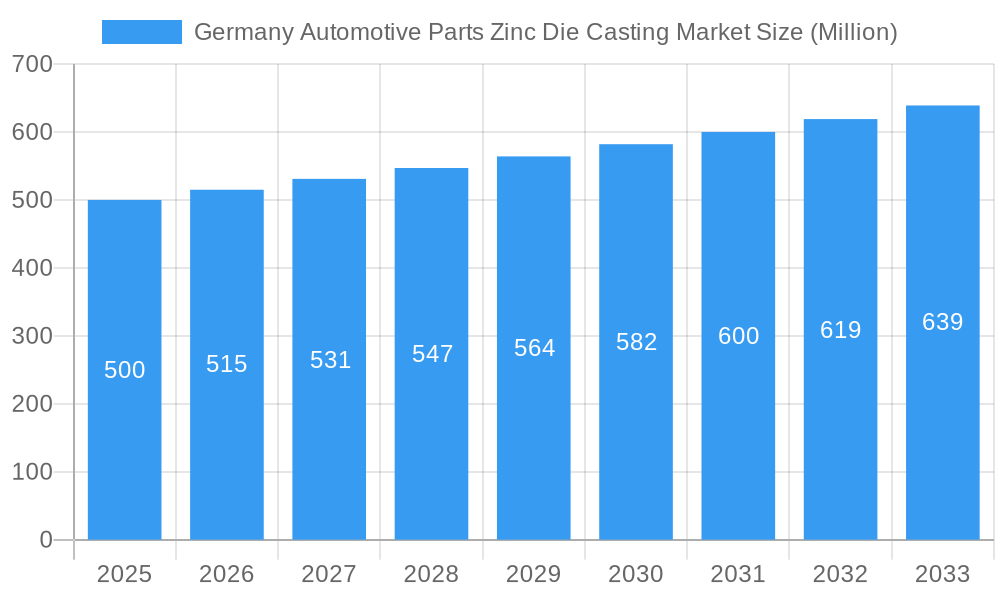

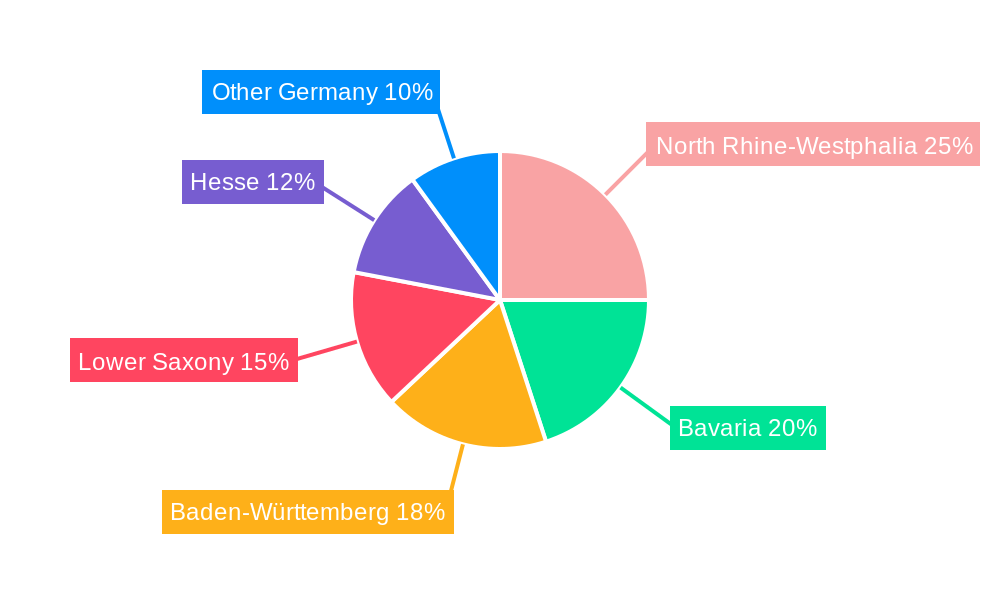

The German automotive parts zinc die casting market is poised for significant expansion, driven by the increasing demand for lightweight, high-strength components. The market is projected to reach $6.08 billion by 2033, exhibiting a Compound Annual Growth Rate (CAGR) of 5.6% from the base year 2025. Key growth catalysts include the accelerating adoption of electric vehicles (EVs), which necessitates lightweight materials for enhanced energy efficiency and range, alongside stringent fuel efficiency regulations compelling automakers to adopt lighter materials. The growing complexity of automotive designs and the integration of advanced features further amplify the demand for intricate zinc die-cast parts. The market is segmented by production process, including pressure die casting and vacuum die casting, and by application, such as body assemblies and engine components. Pressure die casting currently leads due to its cost-effectiveness and scalability, while vacuum die casting is gaining prominence for its superior surface finish and dimensional accuracy. The strong presence of established automotive manufacturers and a robust supply chain within Germany are significant contributors to market growth, with regions like North Rhine-Westphalia, Bavaria, Baden-Württemberg, Lower Saxony, and Hesse being key contributors owing to established automotive clusters and a skilled workforce. Potential challenges include raw material price volatility and rising labor costs. The competitive landscape features both global and regional players, fostering ongoing innovation.

Germany Automotive Parts Zinc Die Casting Market Market Size (In Billion)

Looking ahead, market expansion will be propelled by technological advancements in die casting, the continued growth of the EV sector, and the persistent demand for higher-quality, durable automotive components. Investments in R&D focused on process efficiency, precision, and novel alloy development will be crucial. Despite challenges posed by raw material costs and economic uncertainties, fundamental growth drivers are expected to sustain the market's positive trajectory. The strategic emphasis on lightweighting, improved fuel efficiency, and enhanced vehicle safety will continue to be primary drivers for zinc die casting components in the German automotive industry.

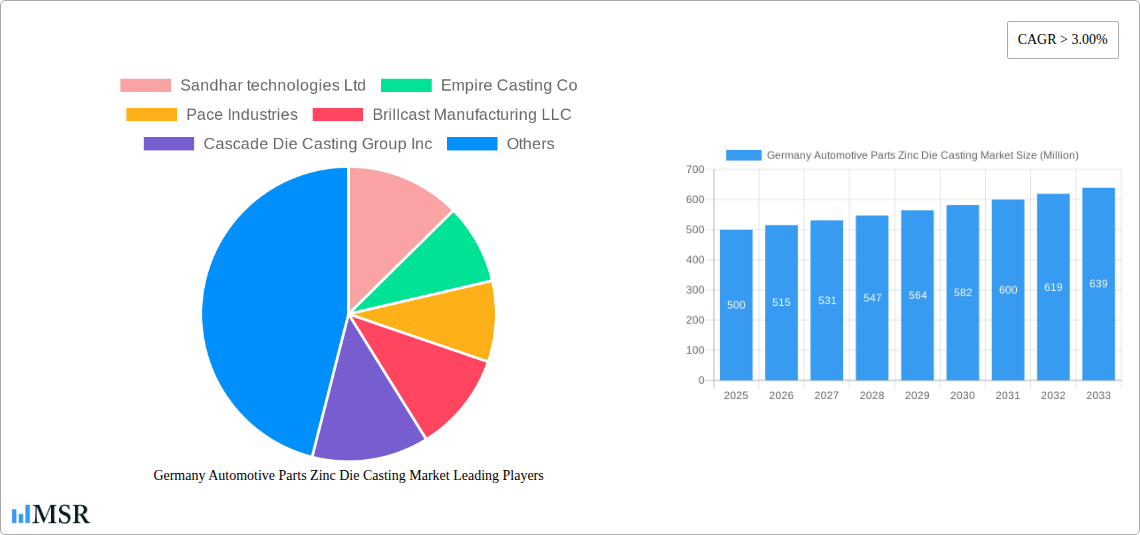

Germany Automotive Parts Zinc Die Casting Market Company Market Share

Germany Automotive Parts Zinc Die Casting Market: A Comprehensive Report (2019-2033)

This in-depth report provides a comprehensive analysis of the Germany automotive parts zinc die casting market, offering invaluable insights for stakeholders seeking to navigate this dynamic sector. Covering the period 2019-2033, with a base year of 2025 and a forecast period of 2025-2033, this report meticulously examines market dynamics, trends, and opportunities. The study incorporates data from the historical period (2019-2024) and leverages robust methodologies to predict future market behavior. Key players like Sandhar technologies Ltd, Empire Casting Co, Pace Industries, Brillcast Manufacturing LLC, Cascade Die Casting Group Inc, Ningbo Die Casting Company, Ashook Minda Grou, Dynacast, and Kemlows Diecasting Products Ltd are profiled, offering a granular view of the competitive landscape. The market is segmented by production process type (pressure die casting, vacuum die casting, other production process types) and application type (body assemblies, engine parts, transmission parts, other application types).

Germany Automotive Parts Zinc Die Casting Market Market Concentration & Dynamics

This section delves into the competitive intensity of the German automotive parts zinc die casting market. We analyze market concentration, assessing the market share held by key players and identifying any dominant firms. The report also explores the innovative ecosystem, examining R&D activities, technological advancements, and the role of partnerships and collaborations. Regulatory frameworks impacting the industry, including environmental regulations and safety standards, are thoroughly analyzed. Further, we assess the impact of substitute products and materials on market dynamics, considering their price competitiveness and performance characteristics. Finally, we examine end-user trends, such as the growing demand for lightweight vehicles and the adoption of advanced driver-assistance systems (ADAS), and analyze their influence on market growth. The analysis also incorporates an examination of M&A activities within the sector, including deal counts and their impact on market consolidation. We estimate the market size at XX Million in 2025 and predict a CAGR of xx% for the forecast period.

Germany Automotive Parts Zinc Die Casting Market Industry Insights & Trends

This section provides a detailed analysis of the factors driving market growth, including economic expansion within the German automotive industry, increasing demand for zinc die-cast components due to their lightweight and durable nature, and the ongoing trend toward vehicle electrification. We further analyze technological disruptions, such as the adoption of advanced die casting technologies and automation in the production process. The influence of evolving consumer preferences, including preferences for sustainable and high-performance vehicles, is examined. The impact of these factors on market size and CAGR are quantified, providing a clear picture of the market's trajectory. Specific trends such as the rising adoption of electric vehicles and the resulting need for lightweight components are explored, along with their impact on the demand for zinc die castings. The report also examines the challenges posed by fluctuating raw material prices and potential supply chain disruptions. The market size is projected to reach XX Million by 2033.

Key Markets & Segments Leading Germany Automotive Parts Zinc Die Casting Market

This section identifies the dominant segments within the German automotive parts zinc die casting market.

Production Process Type: Pressure die casting currently dominates the market due to its cost-effectiveness and high production volume capabilities. However, vacuum die casting is gaining traction due to its ability to produce high-quality components with intricate designs. Other production process types constitute a smaller segment. The growth of pressure die casting is driven by the increasing demand for automotive components in the mass production sector. Vacuum die casting's growth is fueled by the demand for higher-quality, complex parts in high-end vehicles.

Application Type: Engine parts currently hold a significant market share, owing to the critical role of zinc die castings in engine components. Body assemblies are another major application area, with significant demand driven by the growing preference for lightweight vehicles. Transmission parts represent a smaller but growing segment. Growth drivers for engine parts include advancements in engine technology, resulting in increased demand for high-precision zinc die-cast components. Growth drivers for body assemblies include the continuing demand for fuel-efficient vehicles requiring lightweight parts.

The report provides a detailed analysis of each segment's market size, growth drivers, and future potential. Germany is identified as the dominant market within the region, fuelled by a strong automotive manufacturing base and technological advancements.

Germany Automotive Parts Zinc Die Casting Market Product Developments

Recent years have witnessed significant advancements in zinc die casting technology, including the development of high-strength alloys and improved surface finishing techniques. These innovations have expanded the applications of zinc die castings in automotive parts, allowing for the production of more complex and durable components. The market is also witnessing a rise in the adoption of automation and robotics in die casting processes, improving efficiency and reducing production costs. This technological progress is providing manufacturers with a competitive edge, enabling them to meet the evolving demands of the automotive industry.

Challenges in the Germany Automotive Parts Zinc Die Casting Market Market

The German automotive parts zinc die casting market faces several challenges. Fluctuating zinc prices pose a significant risk, impacting profitability. Stringent environmental regulations require manufacturers to adopt sustainable production practices, increasing operational costs. Intense competition from other materials, such as aluminum and plastics, also presents a challenge. Supply chain disruptions caused by geopolitical instability can affect the availability of raw materials and components, creating production bottlenecks and impacting the delivery timelines of finished products. These challenges lead to an estimated loss of xx Million annually.

Forces Driving Germany Automotive Parts Zinc Die Casting Market Growth

The growth of the German automotive parts zinc die casting market is propelled by several key factors. The increasing demand for lightweight vehicles to enhance fuel efficiency is a major driver. The rising adoption of advanced driver-assistance systems (ADAS) requires intricate and lightweight components, further boosting demand for zinc die castings. Government initiatives promoting sustainable manufacturing practices and technological advancements in die casting processes are also contributing to market growth. Economic growth in Germany and the broader European Union supports the overall growth of the automotive industry, in turn driving demand for automotive components.

Long-Term Growth Catalysts in the Germany Automotive Parts Zinc Die Casting Market

Long-term growth in the German automotive parts zinc die casting market is expected to be fueled by several key factors. Innovation in die casting technology, leading to improved component design and performance, will be a crucial driver. Strategic partnerships and collaborations between die casters and automotive manufacturers will streamline supply chains and foster technological development. The expansion into new markets and applications within the automotive sector will provide additional growth opportunities. Continued investments in research and development will be critical to sustaining long-term competitiveness and innovation within the sector.

Emerging Opportunities in Germany Automotive Parts Zinc Die Casting Market

Emerging opportunities within the German automotive parts zinc die casting market include the growing demand for electric vehicles (EVs), requiring lightweight and high-precision components. The increasing adoption of advanced materials and surface treatments enhances component performance and aesthetics. The expansion into niche applications, such as battery casings and other EV-specific components, presents significant growth potential. Exploring new markets outside of the traditional automotive industry, such as consumer electronics and medical devices, could also diversify revenue streams.

Leading Players in the Germany Automotive Parts Zinc Die Casting Market Sector

- Sandhar technologies Ltd

- Empire Casting Co

- Pace Industries

- Brillcast Manufacturing LLC

- Cascade Die Casting Group Inc

- Ningbo Die Casting Company

- Ashook Minda Grou

- Dynacast

- Kemlows Diecasting Products Ltd

Key Milestones in Germany Automotive Parts Zinc Die Casting Market Industry

- 2020: Introduction of a new high-strength zinc alloy by a leading die caster.

- 2022: Major automotive manufacturer partners with a die casting company for the development of lightweight EV components.

- 2023: Significant investment in automation and robotics by a prominent die casting facility.

- 2024: Launch of a new vacuum die casting facility specializing in high-precision automotive parts.

Strategic Outlook for Germany Automotive Parts Zinc Die Casting Market Market

The future of the German automotive parts zinc die casting market is promising, driven by continued technological advancements, increasing demand for lightweight vehicles, and the expansion of the electric vehicle market. Strategic opportunities exist for companies that invest in research and development, adopt sustainable manufacturing practices, and forge strong partnerships within the automotive supply chain. By capitalizing on these opportunities, companies can secure a significant market share and drive sustainable growth in the coming years. The market is poised for strong growth, with the potential to reach XX Million by 2033.

Germany Automotive Parts Zinc Die Casting Market Segmentation

-

1. Production Process Type

- 1.1. Pressure Die Casting

- 1.2. Vacuum Die Casting

- 1.3. Other Productino Process Types

-

2. Application Type

- 2.1. Body Assemblies

- 2.2. Engine Parts

- 2.3. Transmission Parts

- 2.4. Other Aplication Types

Germany Automotive Parts Zinc Die Casting Market Segmentation By Geography

- 1. Germany

Germany Automotive Parts Zinc Die Casting Market Regional Market Share

Geographic Coverage of Germany Automotive Parts Zinc Die Casting Market

Germany Automotive Parts Zinc Die Casting Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 5.6% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Growth of the Automotive Industry to Drive Demand in the Die Casting Market

- 3.3. Market Restrains

- 3.3.1. High Processing Cost May Hamper Market Expansion

- 3.4. Market Trends

- 3.4.1. Rising Demand for Vacuum Die Casting and Enactment of Stringent Emission Regulations

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Germany Automotive Parts Zinc Die Casting Market Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Production Process Type

- 5.1.1. Pressure Die Casting

- 5.1.2. Vacuum Die Casting

- 5.1.3. Other Productino Process Types

- 5.2. Market Analysis, Insights and Forecast - by Application Type

- 5.2.1. Body Assemblies

- 5.2.2. Engine Parts

- 5.2.3. Transmission Parts

- 5.2.4. Other Aplication Types

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. Germany

- 5.1. Market Analysis, Insights and Forecast - by Production Process Type

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 Sandhar technologies Ltd

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Empire Casting Co

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 Pace Industries

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Brillcast Manufacturing LLC

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 Cascade Die Casting Group Inc

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Ningbo Die Casting Company

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 Ashook Minda Grou

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 Dynacast

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 Kemlows Diecasting Products Ltd

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.1 Sandhar technologies Ltd

List of Figures

- Figure 1: Germany Automotive Parts Zinc Die Casting Market Revenue Breakdown (billion, %) by Product 2025 & 2033

- Figure 2: Germany Automotive Parts Zinc Die Casting Market Share (%) by Company 2025

List of Tables

- Table 1: Germany Automotive Parts Zinc Die Casting Market Revenue billion Forecast, by Production Process Type 2020 & 2033

- Table 2: Germany Automotive Parts Zinc Die Casting Market Revenue billion Forecast, by Application Type 2020 & 2033

- Table 3: Germany Automotive Parts Zinc Die Casting Market Revenue billion Forecast, by Region 2020 & 2033

- Table 4: Germany Automotive Parts Zinc Die Casting Market Revenue billion Forecast, by Production Process Type 2020 & 2033

- Table 5: Germany Automotive Parts Zinc Die Casting Market Revenue billion Forecast, by Application Type 2020 & 2033

- Table 6: Germany Automotive Parts Zinc Die Casting Market Revenue billion Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Germany Automotive Parts Zinc Die Casting Market?

The projected CAGR is approximately 5.6%.

2. Which companies are prominent players in the Germany Automotive Parts Zinc Die Casting Market?

Key companies in the market include Sandhar technologies Ltd, Empire Casting Co, Pace Industries, Brillcast Manufacturing LLC, Cascade Die Casting Group Inc, Ningbo Die Casting Company, Ashook Minda Grou, Dynacast, Kemlows Diecasting Products Ltd.

3. What are the main segments of the Germany Automotive Parts Zinc Die Casting Market?

The market segments include Production Process Type, Application Type.

4. Can you provide details about the market size?

The market size is estimated to be USD 6.08 billion as of 2022.

5. What are some drivers contributing to market growth?

Growth of the Automotive Industry to Drive Demand in the Die Casting Market.

6. What are the notable trends driving market growth?

Rising Demand for Vacuum Die Casting and Enactment of Stringent Emission Regulations.

7. Are there any restraints impacting market growth?

High Processing Cost May Hamper Market Expansion.

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in billion.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Germany Automotive Parts Zinc Die Casting Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Germany Automotive Parts Zinc Die Casting Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Germany Automotive Parts Zinc Die Casting Market?

To stay informed about further developments, trends, and reports in the Germany Automotive Parts Zinc Die Casting Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

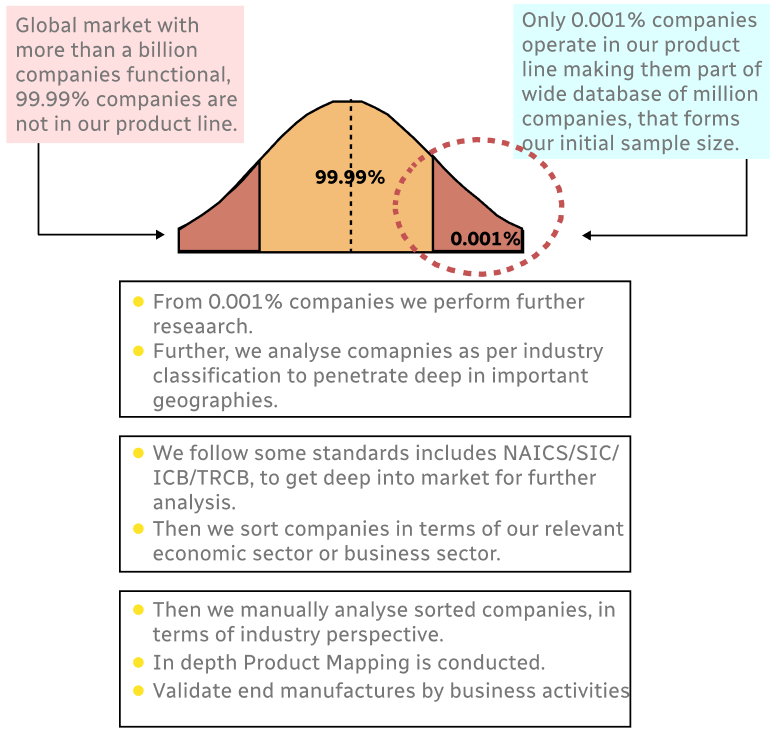

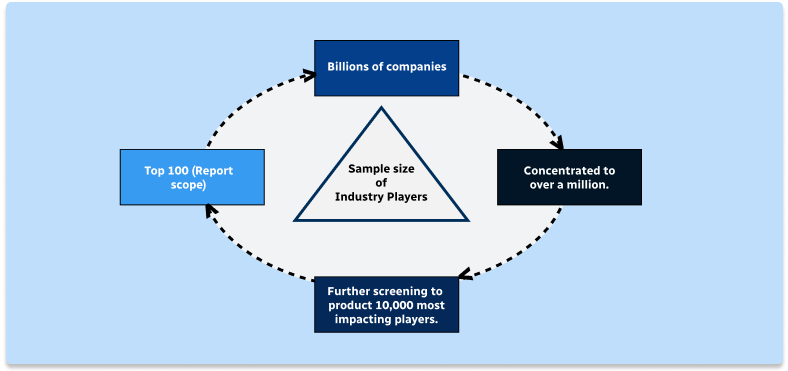

Step 1 - Identification of Relevant Samples Size from Population Database

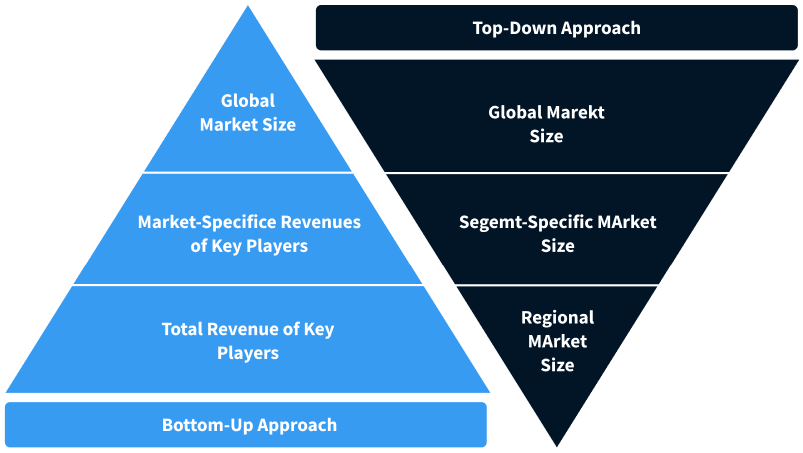

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

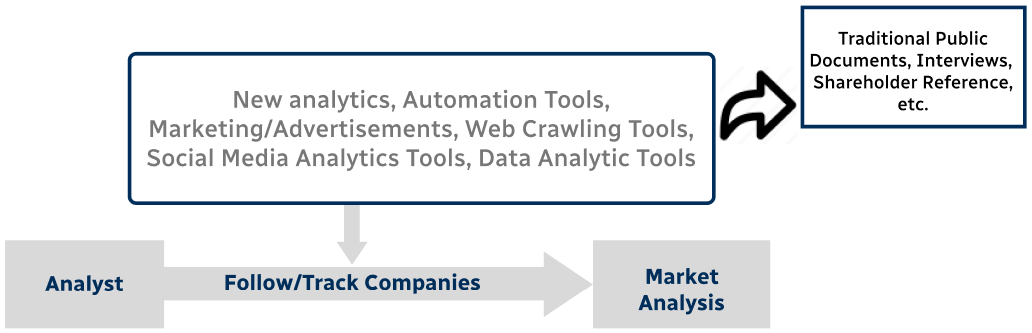

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence