Key Insights

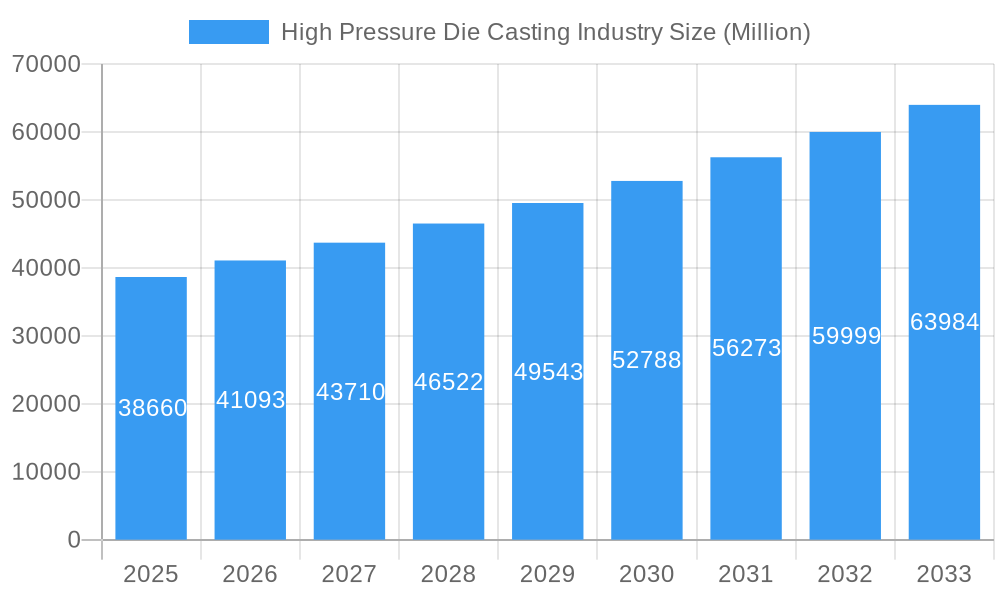

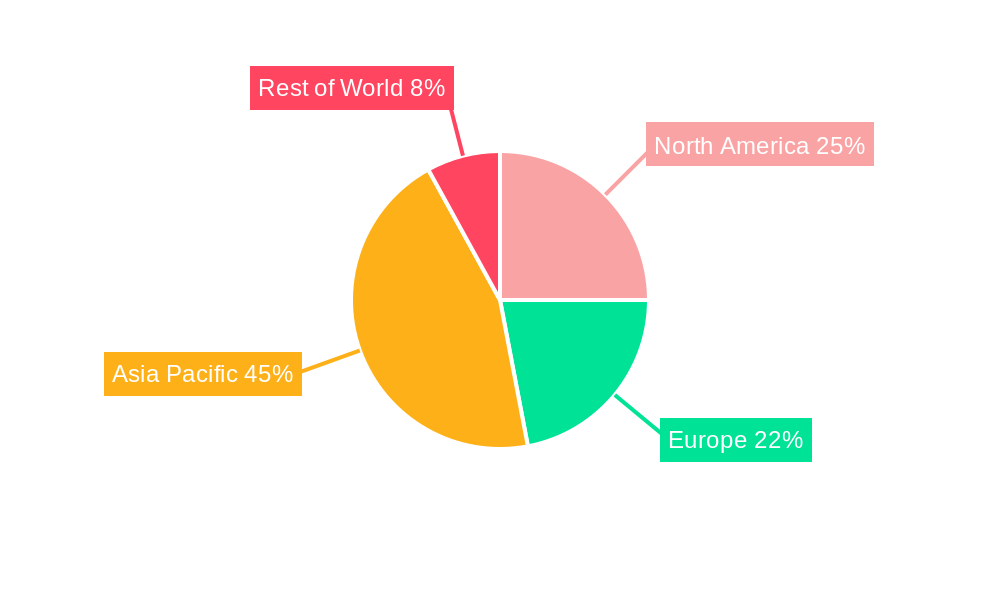

The high-pressure die casting (HPDC) market, valued at $38.66 billion in 2025, is projected to experience robust growth, driven by increasing demand from the automotive and electronics sectors. The automotive industry's shift towards lightweighting initiatives to improve fuel efficiency and reduce emissions fuels significant HPDC adoption. Similarly, the burgeoning electronics industry, particularly in consumer electronics and renewable energy technologies, requires high-precision components readily manufactured through HPDC. The rising adoption of electric vehicles (EVs) further boosts market growth as HPDC plays a crucial role in producing EV components like battery housings and motor casings. Technological advancements in HPDC, such as improved die design and automation, enhance production efficiency and part quality, driving market expansion. While material costs and supply chain disruptions present challenges, the overall market outlook remains positive, with a Compound Annual Growth Rate (CAGR) of 6.16% projected through 2033. Aluminum remains the dominant raw material due to its lightweight and high-strength properties, but magnesium and zinc are gaining traction for specific applications demanding lighter weight or improved corrosion resistance. Geographically, Asia Pacific, particularly China and India, dominates the market due to burgeoning manufacturing hubs and increasing automotive production. North America and Europe also represent significant markets, with a focus on high-value applications and advanced technological integration.

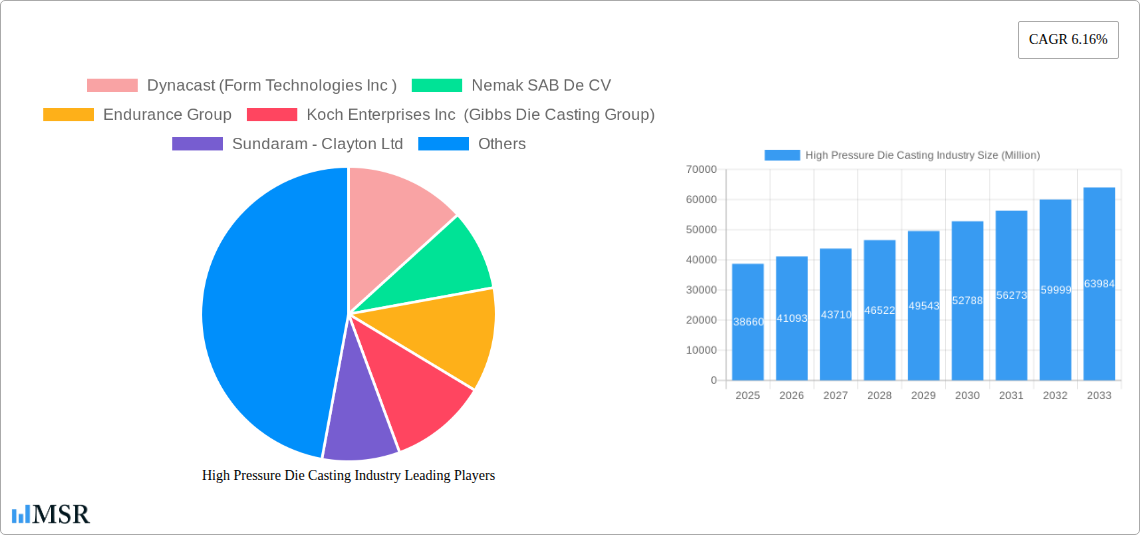

High Pressure Die Casting Industry Market Size (In Billion)

Growth within specific segments will vary. The automotive segment will likely maintain its leading position, driven by the aforementioned trends in lightweighting and EV adoption. However, the electronics and industrial applications segments are also expected to exhibit strong growth, fueled by expanding demand for high-precision components in consumer electronics, industrial automation, and renewable energy infrastructure. While precise market share figures for each segment and region are unavailable, reasonable estimations can be made using available data and industry reports to project future market size. Competitive landscape analysis suggests a mix of large multinational corporations and specialized regional players; intense competition fosters innovation and drives prices. The future success of HPDC manufacturers will depend on their ability to adapt to evolving technological advancements, cater to specific customer needs, and navigate the complexities of global supply chains.

High Pressure Die Casting Industry Company Market Share

High Pressure Die Casting Industry: A Comprehensive Market Report (2019-2033)

This in-depth report provides a comprehensive analysis of the high-pressure die casting industry, covering market dynamics, key segments, leading players, and future growth opportunities. With a study period spanning 2019-2033, a base year of 2025, and a forecast period of 2025-2033, this report offers invaluable insights for industry stakeholders seeking to navigate the complexities and capitalize on the potential of this dynamic sector. The global market size is estimated at USD xx Million in 2025, with a CAGR of xx% projected for the forecast period.

High Pressure Die Casting Industry Market Concentration & Dynamics

The high-pressure die casting market exhibits a moderately concentrated structure, with several multinational corporations holding significant market share. Top players such as Dynacast (Form Technologies Inc), Nemak SAB De CV, and Endurance Group command substantial portions of the market, while other notable players such as Koch Enterprises Inc (Gibbs Die Casting Group), Sundaram-Clayton Ltd, and Georg Fischer AG maintain strong regional presences. Market share fluctuates based on technological advancements, M&A activity, and regional economic performance.

- Market Concentration: The top 5 players hold an estimated xx% market share in 2025.

- Innovation Ecosystems: Significant investment in R&D drives continuous improvement in die-casting processes and materials. The focus is on lightweighting, automation, and sustainable practices.

- Regulatory Frameworks: Environmental regulations are increasingly stringent, influencing material choices and production methods. Compliance costs can impact profitability.

- Substitute Products: Alternative manufacturing techniques such as injection molding and 3D printing present competitive challenges, particularly for certain applications.

- End-User Trends: The automotive sector remains the largest end-user, followed by electrical and electronics. Growing demand for electric vehicles (EVs) is a crucial driver.

- M&A Activities: The past five years have witnessed xx major M&A deals in the high-pressure die casting industry, indicating consolidation and strategic expansion efforts.

High Pressure Die Casting Industry Industry Insights & Trends

The high-pressure die casting industry is experiencing robust growth, driven primarily by rising demand from the automotive and electronics sectors. The automotive industry's shift towards lighter vehicles and increased adoption of electric vehicles (EVs) has fueled demand for high-pressure die casting components. Technological advancements such as automation and AI-powered process optimization are enhancing efficiency and productivity. Evolving consumer preferences for durable, lightweight, and cost-effective products are contributing to the industry's growth trajectory. The market size is estimated to reach USD xx Million by 2033.

Key Markets & Segments Leading High Pressure Die Casting Industry

The automotive sector is the dominant application segment, accounting for approximately xx% of the total market share in 2025. Aluminum is the leading raw material, followed by zinc and magnesium. Geographically, Asia Pacific is the leading region, driven by strong automotive production and expanding electronics manufacturing.

- Raw Material Type:

- Aluminum: High demand due to its lightweight properties and suitability for automotive applications.

- Zinc: Cost-effective option for various applications, particularly in electronics.

- Magnesium: Growing popularity in automotive applications due to its lightweight nature and high strength-to-weight ratio.

- Application:

- Automotive: Dominant segment, driven by light weighting trends and EV adoption.

- Electrical and Electronics: Strong demand for miniaturized and high-precision components.

- Industrial Applications: Growth driven by increasing automation and demand for durable components.

- Other Applications: Includes diverse sectors like aerospace and medical devices.

- Regional Dominance: Asia Pacific dominates the market due to substantial automotive and electronics manufacturing. North America and Europe also hold significant market shares.

- Drivers: Economic growth, robust industrial infrastructure, and increasing manufacturing capabilities contribute to regional dominance.

High Pressure Die Casting Industry Product Developments

Recent product innovations focus on advanced materials, optimized casting processes, and surface finishing techniques. Companies are developing high-strength aluminum alloys, implementing automation and AI for better precision and efficiency, and exploring sustainable casting solutions. These improvements enhance product performance, reduce costs, and meet evolving environmental regulations.

Challenges in the High Pressure Die Casting Industry Market

The industry faces challenges such as fluctuating raw material prices, supply chain disruptions, and intense competition. Stringent environmental regulations necessitate significant investments in compliance measures. The increasing adoption of alternative manufacturing methods further adds to competitive pressures. These factors can impact profitability and overall growth.

Forces Driving High Pressure Die Casting Industry Growth

The industry's growth is propelled by technological advancements in casting processes, the rising demand for lightweight components in the automotive and aerospace sectors, and the ongoing expansion of the electronics manufacturing industry. Government incentives for sustainable manufacturing and the increasing adoption of electric vehicles further boost the growth outlook.

Challenges in the High Pressure Die Casting Industry Market

Long-term growth is dependent on continuous innovation in materials and processes, strategic partnerships to expand market access, and a proactive approach to environmental sustainability. Investments in R&D and skilled labor remain crucial for long-term success.

Emerging Opportunities in High Pressure Die Casting Industry

Emerging opportunities include the expanding EV market, the growing adoption of lightweight materials in various applications, and the development of sustainable and environmentally friendly casting techniques. Further penetration into niche markets and strategic collaborations can unlock substantial growth prospects.

Leading Players in the High Pressure Die Casting Industry Sector

- Dynacast (Form Technologies Inc)

- Nemak SAB De CV

- Endurance Group

- Koch Enterprises Inc (Gibbs Die Casting Group)

- Sundaram-Clayton Ltd

- Georg Fischer AG

- Ryobi Die Casting Inc

- Rheinmetall AG (Rheinmetall Automotive formerly KSPG AG)

- Officine Meccaniche Rezzatesi SpA

- Rockman Industries

- Engtek Group

- Shiloh Industries Ltd

Key Milestones in High Pressure Die Casting Industry Industry

- November 2022: Pace Industries closes two Muskegon die-casting plants, impacting aluminum and zinc die casting supply in the automotive sector.

- September 2022: Rheinmetall AG secures a USD 236 Million order for its Turbo Bypass Valve, boosting its position in the automotive components market.

- May 2022: GF Casting Solutions commits to enhancing EV production, leveraging AI and sustainability initiatives to capitalize on the growing e-mobility market.

Strategic Outlook for High Pressure Die Casting Industry Market

The high-pressure die casting industry is poised for substantial growth, driven by the automotive sector's transition to electric vehicles and the rising demand for lightweight components across various industries. Strategic investments in automation, sustainable materials, and technological innovation will be crucial for companies seeking to thrive in this evolving landscape. The focus on partnerships and geographical expansion will further enhance market penetration and competitiveness.

High Pressure Die Casting Industry Segmentation

-

1. Raw Material Type

- 1.1. Aluminum

- 1.2. Zinc

- 1.3. Magnesium

-

2. Application

- 2.1. Automotive

- 2.2. Electrical and Electronics

- 2.3. Industrial Applications

- 2.4. Other Applications

-

3. Production Process

- 3.1. Vacuum High-pressure Die Casting

- 3.2. Squeeze High-pressure Die Casting

High Pressure Die Casting Industry Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Rest of North America

-

2. Europe

- 2.1. Germany

- 2.2. United Kingdom

- 2.3. France

- 2.4. Italy

- 2.5. Rest of Europe

-

3. Asia Pacific

- 3.1. India

- 3.2. China

- 3.3. Japan

- 3.4. South Korea

- 3.5. Rest of Asia Pacific

-

4. Rest of the World

- 4.1. South America

- 4.2. Middle East and Africa

High Pressure Die Casting Industry Regional Market Share

Geographic Coverage of High Pressure Die Casting Industry

High Pressure Die Casting Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 6.16% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Growing Use of Aluminum in Die Casting Equipment to Increase Market Demand

- 3.3. Market Restrains

- 3.3.1. Fluctuations in Raw Material Prices

- 3.4. Market Trends

- 3.4.1. Automotive Segment Expected to Gain Prominence During the Forecast Period

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global High Pressure Die Casting Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Raw Material Type

- 5.1.1. Aluminum

- 5.1.2. Zinc

- 5.1.3. Magnesium

- 5.2. Market Analysis, Insights and Forecast - by Application

- 5.2.1. Automotive

- 5.2.2. Electrical and Electronics

- 5.2.3. Industrial Applications

- 5.2.4. Other Applications

- 5.3. Market Analysis, Insights and Forecast - by Production Process

- 5.3.1. Vacuum High-pressure Die Casting

- 5.3.2. Squeeze High-pressure Die Casting

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. North America

- 5.4.2. Europe

- 5.4.3. Asia Pacific

- 5.4.4. Rest of the World

- 5.1. Market Analysis, Insights and Forecast - by Raw Material Type

- 6. North America High Pressure Die Casting Industry Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Raw Material Type

- 6.1.1. Aluminum

- 6.1.2. Zinc

- 6.1.3. Magnesium

- 6.2. Market Analysis, Insights and Forecast - by Application

- 6.2.1. Automotive

- 6.2.2. Electrical and Electronics

- 6.2.3. Industrial Applications

- 6.2.4. Other Applications

- 6.3. Market Analysis, Insights and Forecast - by Production Process

- 6.3.1. Vacuum High-pressure Die Casting

- 6.3.2. Squeeze High-pressure Die Casting

- 6.1. Market Analysis, Insights and Forecast - by Raw Material Type

- 7. Europe High Pressure Die Casting Industry Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Raw Material Type

- 7.1.1. Aluminum

- 7.1.2. Zinc

- 7.1.3. Magnesium

- 7.2. Market Analysis, Insights and Forecast - by Application

- 7.2.1. Automotive

- 7.2.2. Electrical and Electronics

- 7.2.3. Industrial Applications

- 7.2.4. Other Applications

- 7.3. Market Analysis, Insights and Forecast - by Production Process

- 7.3.1. Vacuum High-pressure Die Casting

- 7.3.2. Squeeze High-pressure Die Casting

- 7.1. Market Analysis, Insights and Forecast - by Raw Material Type

- 8. Asia Pacific High Pressure Die Casting Industry Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Raw Material Type

- 8.1.1. Aluminum

- 8.1.2. Zinc

- 8.1.3. Magnesium

- 8.2. Market Analysis, Insights and Forecast - by Application

- 8.2.1. Automotive

- 8.2.2. Electrical and Electronics

- 8.2.3. Industrial Applications

- 8.2.4. Other Applications

- 8.3. Market Analysis, Insights and Forecast - by Production Process

- 8.3.1. Vacuum High-pressure Die Casting

- 8.3.2. Squeeze High-pressure Die Casting

- 8.1. Market Analysis, Insights and Forecast - by Raw Material Type

- 9. Rest of the World High Pressure Die Casting Industry Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Raw Material Type

- 9.1.1. Aluminum

- 9.1.2. Zinc

- 9.1.3. Magnesium

- 9.2. Market Analysis, Insights and Forecast - by Application

- 9.2.1. Automotive

- 9.2.2. Electrical and Electronics

- 9.2.3. Industrial Applications

- 9.2.4. Other Applications

- 9.3. Market Analysis, Insights and Forecast - by Production Process

- 9.3.1. Vacuum High-pressure Die Casting

- 9.3.2. Squeeze High-pressure Die Casting

- 9.1. Market Analysis, Insights and Forecast - by Raw Material Type

- 10. Competitive Analysis

- 10.1. Global Market Share Analysis 2025

- 10.2. Company Profiles

- 10.2.1 Dynacast (Form Technologies Inc )

- 10.2.1.1. Overview

- 10.2.1.2. Products

- 10.2.1.3. SWOT Analysis

- 10.2.1.4. Recent Developments

- 10.2.1.5. Financials (Based on Availability)

- 10.2.2 Nemak SAB De CV

- 10.2.2.1. Overview

- 10.2.2.2. Products

- 10.2.2.3. SWOT Analysis

- 10.2.2.4. Recent Developments

- 10.2.2.5. Financials (Based on Availability)

- 10.2.3 Endurance Group

- 10.2.3.1. Overview

- 10.2.3.2. Products

- 10.2.3.3. SWOT Analysis

- 10.2.3.4. Recent Developments

- 10.2.3.5. Financials (Based on Availability)

- 10.2.4 Koch Enterprises Inc (Gibbs Die Casting Group)

- 10.2.4.1. Overview

- 10.2.4.2. Products

- 10.2.4.3. SWOT Analysis

- 10.2.4.4. Recent Developments

- 10.2.4.5. Financials (Based on Availability)

- 10.2.5 Sundaram - Clayton Ltd

- 10.2.5.1. Overview

- 10.2.5.2. Products

- 10.2.5.3. SWOT Analysis

- 10.2.5.4. Recent Developments

- 10.2.5.5. Financials (Based on Availability)

- 10.2.6 Georg Fischer AG

- 10.2.6.1. Overview

- 10.2.6.2. Products

- 10.2.6.3. SWOT Analysis

- 10.2.6.4. Recent Developments

- 10.2.6.5. Financials (Based on Availability)

- 10.2.7 Ryobi Die Casting Inc

- 10.2.7.1. Overview

- 10.2.7.2. Products

- 10.2.7.3. SWOT Analysis

- 10.2.7.4. Recent Developments

- 10.2.7.5. Financials (Based on Availability)

- 10.2.8 Rheinmetall AG (Rheinmetall Automotive formerly KSPG AG)

- 10.2.8.1. Overview

- 10.2.8.2. Products

- 10.2.8.3. SWOT Analysis

- 10.2.8.4. Recent Developments

- 10.2.8.5. Financials (Based on Availability)

- 10.2.9 Officine Meccaniche Rezzatesi SpA

- 10.2.9.1. Overview

- 10.2.9.2. Products

- 10.2.9.3. SWOT Analysis

- 10.2.9.4. Recent Developments

- 10.2.9.5. Financials (Based on Availability)

- 10.2.10 Rockman Industries

- 10.2.10.1. Overview

- 10.2.10.2. Products

- 10.2.10.3. SWOT Analysis

- 10.2.10.4. Recent Developments

- 10.2.10.5. Financials (Based on Availability)

- 10.2.11 Engtek Group

- 10.2.11.1. Overview

- 10.2.11.2. Products

- 10.2.11.3. SWOT Analysis

- 10.2.11.4. Recent Developments

- 10.2.11.5. Financials (Based on Availability)

- 10.2.12 Shiloh Industries Ltd

- 10.2.12.1. Overview

- 10.2.12.2. Products

- 10.2.12.3. SWOT Analysis

- 10.2.12.4. Recent Developments

- 10.2.12.5. Financials (Based on Availability)

- 10.2.1 Dynacast (Form Technologies Inc )

List of Figures

- Figure 1: Global High Pressure Die Casting Industry Revenue Breakdown (Million, %) by Region 2025 & 2033

- Figure 2: North America High Pressure Die Casting Industry Revenue (Million), by Raw Material Type 2025 & 2033

- Figure 3: North America High Pressure Die Casting Industry Revenue Share (%), by Raw Material Type 2025 & 2033

- Figure 4: North America High Pressure Die Casting Industry Revenue (Million), by Application 2025 & 2033

- Figure 5: North America High Pressure Die Casting Industry Revenue Share (%), by Application 2025 & 2033

- Figure 6: North America High Pressure Die Casting Industry Revenue (Million), by Production Process 2025 & 2033

- Figure 7: North America High Pressure Die Casting Industry Revenue Share (%), by Production Process 2025 & 2033

- Figure 8: North America High Pressure Die Casting Industry Revenue (Million), by Country 2025 & 2033

- Figure 9: North America High Pressure Die Casting Industry Revenue Share (%), by Country 2025 & 2033

- Figure 10: Europe High Pressure Die Casting Industry Revenue (Million), by Raw Material Type 2025 & 2033

- Figure 11: Europe High Pressure Die Casting Industry Revenue Share (%), by Raw Material Type 2025 & 2033

- Figure 12: Europe High Pressure Die Casting Industry Revenue (Million), by Application 2025 & 2033

- Figure 13: Europe High Pressure Die Casting Industry Revenue Share (%), by Application 2025 & 2033

- Figure 14: Europe High Pressure Die Casting Industry Revenue (Million), by Production Process 2025 & 2033

- Figure 15: Europe High Pressure Die Casting Industry Revenue Share (%), by Production Process 2025 & 2033

- Figure 16: Europe High Pressure Die Casting Industry Revenue (Million), by Country 2025 & 2033

- Figure 17: Europe High Pressure Die Casting Industry Revenue Share (%), by Country 2025 & 2033

- Figure 18: Asia Pacific High Pressure Die Casting Industry Revenue (Million), by Raw Material Type 2025 & 2033

- Figure 19: Asia Pacific High Pressure Die Casting Industry Revenue Share (%), by Raw Material Type 2025 & 2033

- Figure 20: Asia Pacific High Pressure Die Casting Industry Revenue (Million), by Application 2025 & 2033

- Figure 21: Asia Pacific High Pressure Die Casting Industry Revenue Share (%), by Application 2025 & 2033

- Figure 22: Asia Pacific High Pressure Die Casting Industry Revenue (Million), by Production Process 2025 & 2033

- Figure 23: Asia Pacific High Pressure Die Casting Industry Revenue Share (%), by Production Process 2025 & 2033

- Figure 24: Asia Pacific High Pressure Die Casting Industry Revenue (Million), by Country 2025 & 2033

- Figure 25: Asia Pacific High Pressure Die Casting Industry Revenue Share (%), by Country 2025 & 2033

- Figure 26: Rest of the World High Pressure Die Casting Industry Revenue (Million), by Raw Material Type 2025 & 2033

- Figure 27: Rest of the World High Pressure Die Casting Industry Revenue Share (%), by Raw Material Type 2025 & 2033

- Figure 28: Rest of the World High Pressure Die Casting Industry Revenue (Million), by Application 2025 & 2033

- Figure 29: Rest of the World High Pressure Die Casting Industry Revenue Share (%), by Application 2025 & 2033

- Figure 30: Rest of the World High Pressure Die Casting Industry Revenue (Million), by Production Process 2025 & 2033

- Figure 31: Rest of the World High Pressure Die Casting Industry Revenue Share (%), by Production Process 2025 & 2033

- Figure 32: Rest of the World High Pressure Die Casting Industry Revenue (Million), by Country 2025 & 2033

- Figure 33: Rest of the World High Pressure Die Casting Industry Revenue Share (%), by Country 2025 & 2033

List of Tables

- Table 1: Global High Pressure Die Casting Industry Revenue Million Forecast, by Raw Material Type 2020 & 2033

- Table 2: Global High Pressure Die Casting Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 3: Global High Pressure Die Casting Industry Revenue Million Forecast, by Production Process 2020 & 2033

- Table 4: Global High Pressure Die Casting Industry Revenue Million Forecast, by Region 2020 & 2033

- Table 5: Global High Pressure Die Casting Industry Revenue Million Forecast, by Raw Material Type 2020 & 2033

- Table 6: Global High Pressure Die Casting Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 7: Global High Pressure Die Casting Industry Revenue Million Forecast, by Production Process 2020 & 2033

- Table 8: Global High Pressure Die Casting Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 9: United States High Pressure Die Casting Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 10: Canada High Pressure Die Casting Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 11: Rest of North America High Pressure Die Casting Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 12: Global High Pressure Die Casting Industry Revenue Million Forecast, by Raw Material Type 2020 & 2033

- Table 13: Global High Pressure Die Casting Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 14: Global High Pressure Die Casting Industry Revenue Million Forecast, by Production Process 2020 & 2033

- Table 15: Global High Pressure Die Casting Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 16: Germany High Pressure Die Casting Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 17: United Kingdom High Pressure Die Casting Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 18: France High Pressure Die Casting Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 19: Italy High Pressure Die Casting Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 20: Rest of Europe High Pressure Die Casting Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 21: Global High Pressure Die Casting Industry Revenue Million Forecast, by Raw Material Type 2020 & 2033

- Table 22: Global High Pressure Die Casting Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 23: Global High Pressure Die Casting Industry Revenue Million Forecast, by Production Process 2020 & 2033

- Table 24: Global High Pressure Die Casting Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 25: India High Pressure Die Casting Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 26: China High Pressure Die Casting Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 27: Japan High Pressure Die Casting Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 28: South Korea High Pressure Die Casting Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 29: Rest of Asia Pacific High Pressure Die Casting Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 30: Global High Pressure Die Casting Industry Revenue Million Forecast, by Raw Material Type 2020 & 2033

- Table 31: Global High Pressure Die Casting Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 32: Global High Pressure Die Casting Industry Revenue Million Forecast, by Production Process 2020 & 2033

- Table 33: Global High Pressure Die Casting Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 34: South America High Pressure Die Casting Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 35: Middle East and Africa High Pressure Die Casting Industry Revenue (Million) Forecast, by Application 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the High Pressure Die Casting Industry?

The projected CAGR is approximately 6.16%.

2. Which companies are prominent players in the High Pressure Die Casting Industry?

Key companies in the market include Dynacast (Form Technologies Inc ), Nemak SAB De CV, Endurance Group, Koch Enterprises Inc (Gibbs Die Casting Group), Sundaram - Clayton Ltd, Georg Fischer AG, Ryobi Die Casting Inc, Rheinmetall AG (Rheinmetall Automotive formerly KSPG AG), Officine Meccaniche Rezzatesi SpA, Rockman Industries, Engtek Group, Shiloh Industries Ltd.

3. What are the main segments of the High Pressure Die Casting Industry?

The market segments include Raw Material Type, Application, Production Process.

4. Can you provide details about the market size?

The market size is estimated to be USD 38.66 Million as of 2022.

5. What are some drivers contributing to market growth?

Growing Use of Aluminum in Die Casting Equipment to Increase Market Demand.

6. What are the notable trends driving market growth?

Automotive Segment Expected to Gain Prominence During the Forecast Period.

7. Are there any restraints impacting market growth?

Fluctuations in Raw Material Prices.

8. Can you provide examples of recent developments in the market?

November 2022: Pace Industries, one of the leading die-casting companies in the United States, announced the closure of its two Muskegon die-casting plants. The company manufactures aluminum die castings, zinc die castings, mechanical assemblies, and injected molded plastics for the automotive industry.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "High Pressure Die Casting Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the High Pressure Die Casting Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the High Pressure Die Casting Industry?

To stay informed about further developments, trends, and reports in the High Pressure Die Casting Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

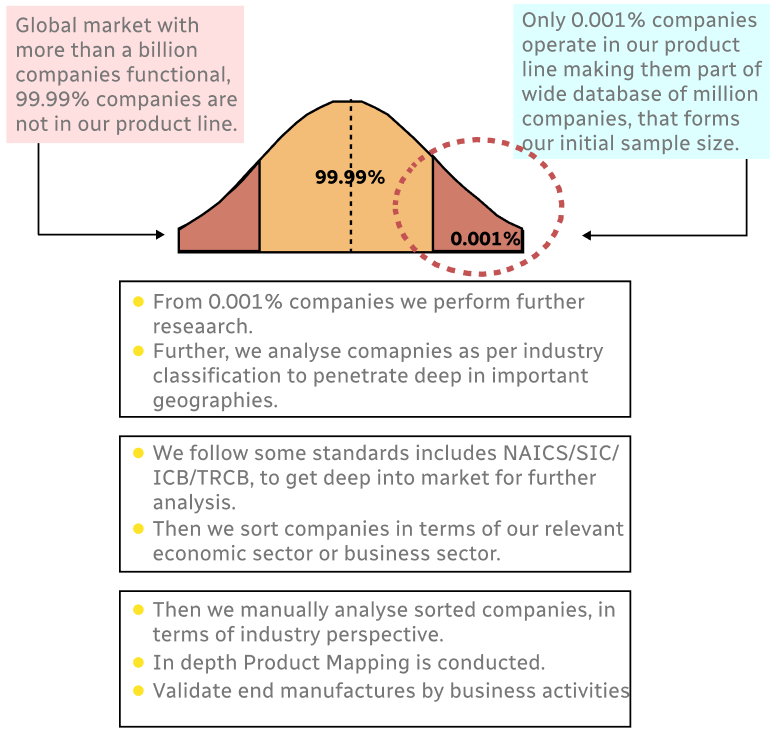

Step 1 - Identification of Relevant Samples Size from Population Database

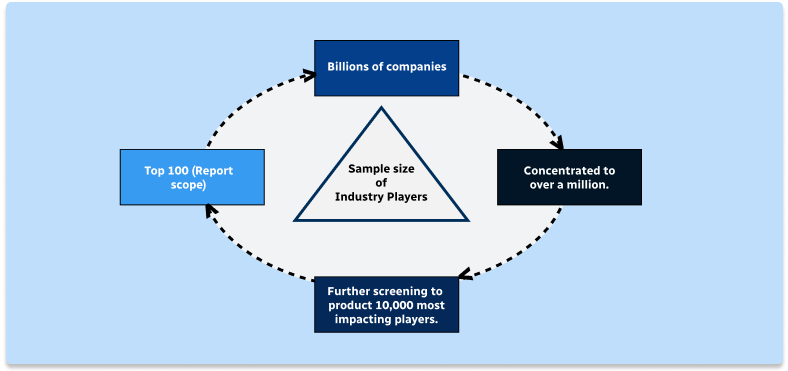

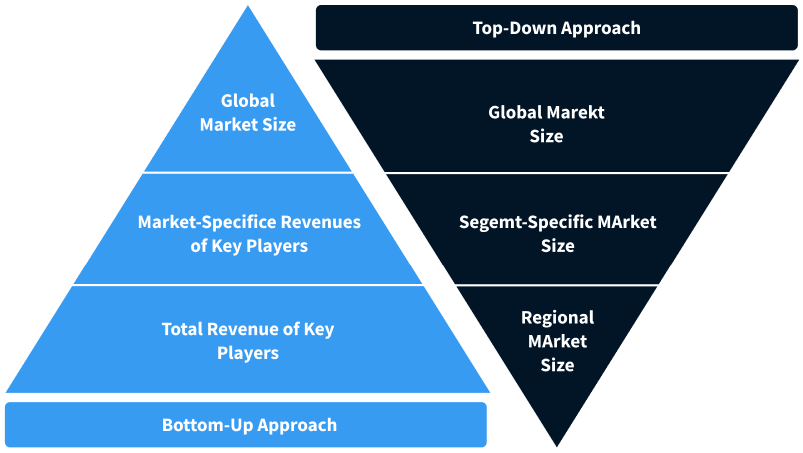

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

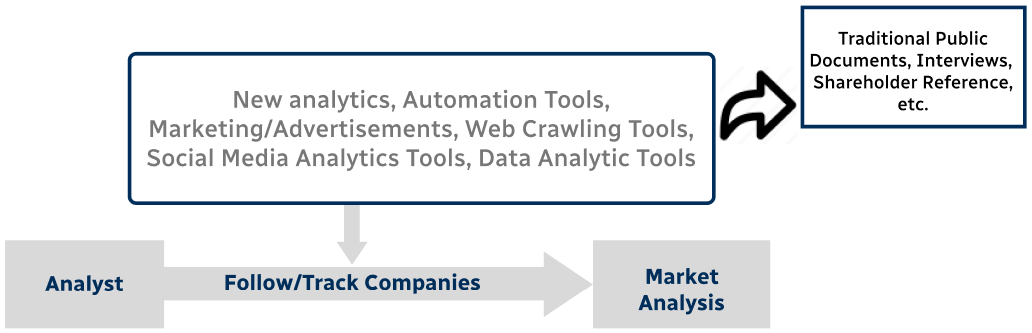

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence